What Are Rogers ARLON Industrial Cellular Silicones?

Rogers ARLON Industrial Cellular Silicones are a range of lightweight, flexible foam materials made by Rogers Corporation. They are used in a variety of industrial applications where lightweight, thermal insulation and vibration dampening properties are needed.

Some key features of Rogers ARLON Industrial Cellular Silicones include:

- Low density and lightweight

- Good thermal insulation properties

- Excellent vibration dampening abilities

- Flexible and compressible

- Resilient structure

- Wide operating temperature range

- Good dielectric properties

- Resistant to weathering and UV

Applications of Rogers ARLON Industrial Cellular Silicones

Rogers ARLON Industrial Cellular Silicones are used in a diverse range of industrial sectors and applications:

Transportation:

- Automotive underbody shields

- Train and subway car flooring

- Marine vessel insulation

Industrial:

- Pipe and duct insulation

- Acoustic barriers

- Commercial refrigeration insulation

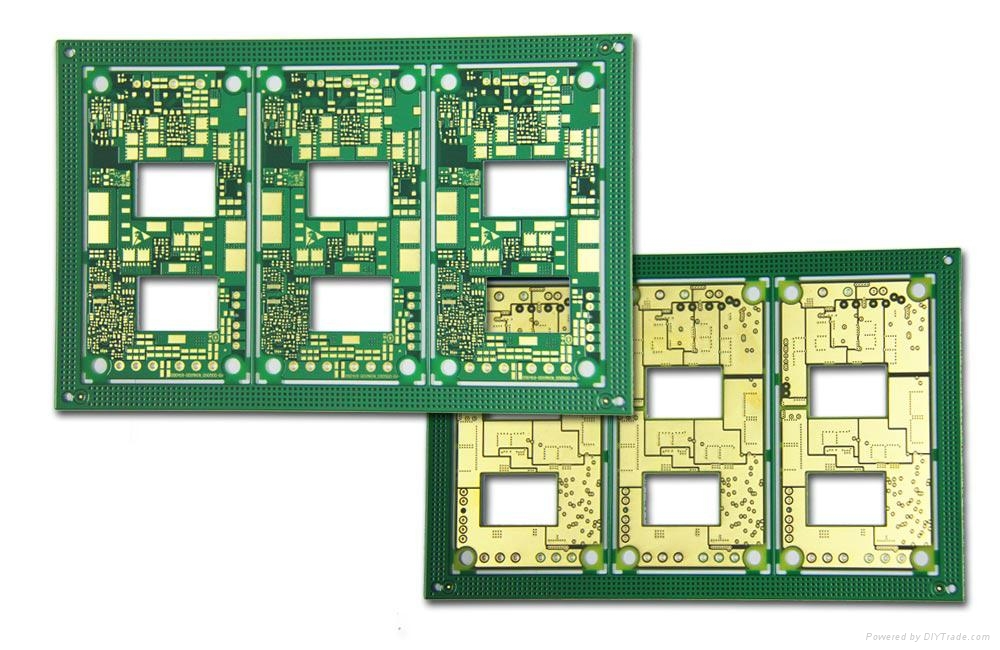

Electronics:

- Electrical enclosures and cable insulation

- Thermal interface pads

- Keyboard and keypads

Construction:

- HVAC duct liners

- Pipe insulation

- Roofing and cladding

Types of Rogers ARLON Industrial Cellular Silicones

Rogers offers a wide range of ARLON silicone foam products with different densities, cell structures and properties for optimal performance in various applications:

| Product | Description |

|---|---|

| ARLON 1100 | Ultra-low density, open cell silicone foam |

| ARLON 1102 | Low density, open cell silicone foam |

| ARLON 1104 | Medium density, open cell silicone foam |

| ARLON 1106 | Higher density, open cell silicone foam |

| ARLON 1250 | Medium density, closed cell silicone foam |

| ARLON 1252 | Higher density, closed cell silicone foam |

Benefits of Using Rogers ARLON Industrial Cellular Silicones

Some of the key benefits that make Rogers ARLON silicone foams useful across industrial applications include:

- Lightweight – Low density foams are extremely lightweight, making them useful for applications where weight reduction is critical.

- Thermal insulation – Low thermal conductivity provides effective insulation for hot or cold temperature management.

- Vibration dampening – Excellent acoustic dampening helps reduce noise and vibration.

- Resilient – Retains original shape and properties after compression or impact.

- Flexible – Can conform to curved or irregular shapes.

- Weather/UV resistance – Suitable for outdoor applications and harsh environments.

- Flame resistance – Meets flame retardancy standards for industrial safety.

Conclusion

Rogers ARLON Industrial Cellular Silicones provide a versatile range of lightweight, resilient foam materials for diverse industrial applications. Their unique properties like low density, vibration dampening, thermal insulation make them a preferred choice for transportation, industrial, electronics and construction sectors. The wide range of densities and cell structures available allows manufacturers to select the optimal material for their specific application and performance requirements.

Frequently Asked Questions

What industries use Rogers ARLON Industrial Cellular Silicones?

Rogers ARLON silicones are used across transportation, industrial, electronics, HVAC/construction and other industries where lightweight, thermal or acoustic insulation is needed.

What temperature range can Rogers ARLON foams withstand?

Most Rogers ARLON silicone foams can perform in a wide temperature range from -115°C up to +260°C for short periods. Certain specialty products can even go up to +315°C.

Are Rogers ARLON foams flame retardant?

Yes, Rogers ARLON silicone foam products meet flammability standards like UL 94 V-0 and NFPA 130 making them suitable for industrial applications.

Can Rogers ARLON foams be custom fabricated?

Yes, Rogers has in-house fabrication capabilities to provide custom sheets, rolls, die-cuts, laminates, and other shapes based on application requirements.

Do Rogers ARLON foams require any special care or maintenance?

Rogers ARLON foams are generally low maintenance but should be protected from prolonged UV exposure, extreme temperatures outside operating range and solvents/chemicals incompatible with silicone.

Leave a Reply