Why Proper PCB Grounding is Essential

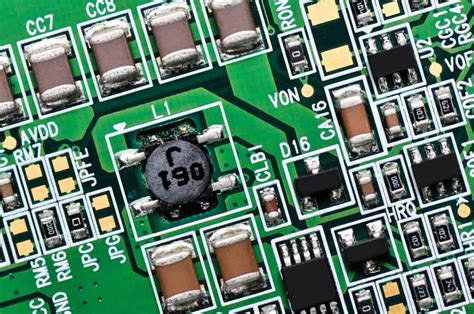

Printed circuit boards (PCBs) are the foundation of virtually all modern electronic devices. They provide the physical structure to mount components and the conductive pathways to electrically connect those components together into functional circuits. One of the most critical aspects of PCB design is proper grounding.

Grounding refers to creating a low-impedance path for current to return to the source, establishing a 0V reference level, and shielding sensitive signals from electromagnetic interference (EMI). Poor grounding can lead to issues like:

- Excess noise and interference

- Signal integrity problems

- Electromagnetic compatibility (EMC) failures

- Unreliable operation

- Overheating or damage to components

On the other hand, a well-grounded PCB will have:

- A stable reference voltage

- Improved signal integrity

- Higher noise immunity

- Better EMI/EMC performance

- Enhanced reliability and product lifetimes

So grounding is not just important for proper circuit operation, but also for ensuring the PCB meets performance and regulatory requirements. Let’s dive into the fundamentals of PCB grounding and best practices to achieve an effective grounding strategy.

Understanding Ground in Electronic Circuits

Before we get into specifics of PCB grounding, it’s helpful to review what ground actually means in the context of electronic circuits. Ground is defined as the reference point in an electrical circuit from which voltages are measured. Any point connected to ground is considered to be at a 0V potential.

However, contrary to what the term may imply, ground is not always connected to the literal earth. In battery-powered devices for instance, ground is simply the negative terminal of the battery. Even in line-powered equipment, the circuit ground may be isolated from the mains earth ground for safety reasons.

The key concept is that ground serves as a common return path for current. For any current flowing through a source, load, or signal, there must be an equal return current flowing back to the source. Ground provides this low-impedance return path, which is essential for the circuit to function.

Another important role of ground is to serve as a shield against electromagnetic interference. Proper grounding helps to contain electric and magnetic fields generated by the circuitry. It prevents those fields from radiating outward and coupling into other circuits as noise. Similarly, a grounded shield can protect the circuit from picking up external EMI.

Types of Ground Connections

Not all ground connections serve the same purpose in a PCB. There are actually several distinct types of grounds that should be considered:

Earth Ground

Also known as protective earth (PE), this refers to a connection to the earth, usually through the grounded conductor in an AC mains outlet. Its primary purpose is safety – to prevent hazardous voltages from appearing on exposed metal parts. Earth ground is typically only relevant for line-powered devices, and may not be present at all in double-insulated or battery-operated equipment.

Chassis Ground

This is any metal enclosure or frame that surrounds the circuitry, such as the metal chassis of a device or a shielding can over a sensitive circuit. The chassis may or may not be connected to earth ground, but it forms an EMI barrier and a safety shield against high voltages.

Analog Ground

Analog ground is a reference specifically for analog circuits on a mixed-signal PCB. It is kept separate from digital ground to avoid digital switching noise from corrupting the sensitive analog signals. Analog and digital grounds should only be connected at a single point.

Digital Ground

Digital or logic ground is the reference for digital circuits. Digital ICs communicate by switching their inputs and outputs between ground and the logic supply voltage. The fast switching causes large transient currents in the supply and ground nets, so digital grounds must be laid out to handle these dynamic loads.

Power Ground

Power ground is the return path for DC power supplies. It carries the bulk of the current drawn by the circuits back to the power source. For low-power circuits, power ground may be combined with digital ground. Higher-power circuits like motor drivers often require a dedicated power ground.

Signal Ground

This is a reference used for communication signals, especially in differential signaling schemes like RS-485 or Ethernet. The signal grounds help to establish a common-mode reference between the transmitter and receiver. They also shield the signal conductors from external EMI.

The following table summarizes the different ground types and their roles:

| Ground Type | Purpose |

|---|---|

| Earth Ground | Safety, EMI shielding, voltage reference |

| Chassis Ground | EMI shielding, safety |

| Analog Ground | 0V reference for analog signals |

| Digital Ground | Return path for digital logic switching currents |

| Power Ground | High-current return for DC power supplies |

| Signal Ground | Common-mode reference and shielding for communication signals |

While each type of ground serves a different purpose, they must still be tied together properly for the overall grounding scheme to be effective. We’ll discuss that in more detail later.

Ground Planes and PCB Layer Stackups

One of the most fundamental decisions in PCB grounding is whether to use a dedicated ground plane. A ground plane is a large area of copper, typically taking up most of a PCB layer, that serves as a low-impedance ground connection. Ground planes offer several advantages:

- Lower impedance compared to narrow ground traces

- Consistent ground potential across the board

- Better heat dissipation

- Improved EMI shielding when combined with power planes

- Easier routing of signal traces

In fact, ground planes have become so ubiquitous that you’d be hard-pressed to find a PCB design without one. Even simple two-layer boards usually dedicate the bottom layer as a ground plane.

The use of ground planes ties into the overall layer stackup of the PCB. The layer stackup refers to the arrangement of copper layers and insulating substrates that make up the board. A typical 4-layer PCB Stackup might look like this:

| Layer | Purpose |

|---|---|

| Top | Signal traces, components |

| Inner 1 | Ground plane |

| Inner 2 | Power plane |

| Bottom | Signal traces, components |

In this stackup, the ground and power planes form a large parallel plate capacitor. This provides a very low impedance between power and ground, helping to decouple the supply. It also creates a controlled impedance environment for signal traces routed on the top and bottom layers.

For more complex designs, additional layers can be added. A 6-layer board might have a signal layer sandwiched between the power and ground planes, allowing for higher routing density. In high-speed digital designs, multiple ground planes are often used, with each signal layer adjacent to a ground plane for improved signal integrity.

When selecting a layer stackup, consider the following:

- Number of layers required for routing and power/ground

- Controlled impedance requirements for high-speed signals

- EMI shielding and containment

- Manufacturing capabilities and costs

Your PCB fabricator can help you choose an appropriate stackup based on your design requirements and budget.

Grounding Strategies for Mixed-Signal PCBs

Grounding becomes more complex when dealing with mixed-signal PCBs that contain both analog and digital circuits. Analog circuits are much more sensitive to noise than digital ones. Even a small amount of digital switching noise coupled into the analog ground can cause problems like jitter, reduced dynamic range, or even complete malfunction.

There are a few different grounding strategies that can be employed in mixed-signal designs to mitigate these issues:

Split Ground Planes

One approach is to physically split the ground plane into separate analog and digital sections. The two ground sections are not connected on the PCB itself. Instead, they are tied together at a single point, usually at the power supply or through a ferrite bead, which helps to isolate high-frequency noise.

The split between analog and digital ground is typically placed under the ADC or DAC that forms the interface between the analog and digital domains. Components are carefully placed so that analog parts are over the analog ground section, and digital parts over the digital section.

Splitting the ground plane like this helps to contain digital noise within the digital section. The single-point connection between the grounds prevents ground loops and ensures that no noise currents can flow through the analog ground.

Hybrid Ground Planes

While split ground planes offer good noise isolation, they make it more difficult to route traces between the analog and digital sections. Each crossing of the split requires a capacitor or resistor bridge to maintain the ground isolation.

An alternative approach is to use a hybrid (or mixed) ground plane. This is a single ground plane that covers the entire PCB, but with separate analog and digital regions. The analog region is connected to the digital region by a thin trace, which forms a single-point connection between the two.

The key difference from a split plane is that the ground regions are not isolated on the PCB itself. This allows traces to cross the boundary without the need for bridges. The thin connecting trace still provides some isolation between the analog and digital regions, but not as much as a complete split.

Hybrid ground planes offer a compromise between the noise isolation of a split plane and the routing flexibility of a single plane. They are often easier to design and manufacture than fully split planes.

Gridded Ground Planes

A third option is to use a grid of ground traces instead of a solid plane. This is sometimes called a “gridded ground” or “hatched ground”. The grid is typically laid out on a 0.1″ or 0.2″ pitch, with the traces sized to handle the expected current.

Gridded grounds have a few potential advantages. They can achieve better impedance control for high-speed signals by adjusting the trace width and spacing. They also save copper compared to solid planes, which can reduce manufacturing costs.

However, gridded grounds are not as effective as solid planes at providing a low-impedance ground connection. They also provide less shielding against EMI. For these reasons, gridded grounds are not as commonly used in modern PCB designs.

Ultimately, the choice of grounding strategy will depend on the specific requirements of your design. Factors to consider include:

- The sensitivity of the analog circuits to digital noise

- The frequency and edge rate of the digital signals

- The routing complexity and layer count of the PCB

- Manufacturing capabilities and cost targets

Simulation tools can be very helpful in evaluating different grounding schemes and predicting their noise performance. It’s also a good idea to prototype and test your grounding strategy on an actual PCB before committing to a full production run.

Best Practices for PCB Grounding

Regardless of the specific grounding strategy used, there are several best practices that should be followed to ensure a robust and effective grounding scheme:

Keep Ground Connections Short

The impedance of a ground connection increases with its length. Therefore, it’s important to keep ground traces and vias as short as possible. Components should be placed close to their ground connections, especially decoupling capacitors.

Where longer ground traces can’t be avoided, they should be made as wide as possible to reduce inductance. Necking down ground traces to route between pins is a common mistake that can cause significant ground bounce issues.

Use Multiple Vias for Ground Connections

Vias have inductance that can limit their effectiveness at high frequencies. Using multiple vias in parallel reduces the overall inductance and provides a lower-impedance ground connection.

This is especially important for decoupling capacitors. A single via can have an inductance of several nanohenries, which limits the capacitor’s effectiveness above a few hundred MHz. Using two or three vias per capacitor pad ensures good high-frequency performance.

Provide Return Paths for High-Speed Signals

High-speed signals should always have a clear return path through ground. Without a continuous ground reference, the signal can couple energy into other traces or radiate EMI.

The return path should be as close as possible to the signal trace to minimize loop area. This is why high-speed signals are often routed between power and ground planes, or on a layer adjacent to a ground plane.

Signals that transition between layers also need a nearby ground via to provide a return path. These vias should be placed within a few millimeters of the signal via, not at the other end of the board.

Avoid Split Planes Under Connectors

Connectors, especially high-speed ones like USB or Ethernet, should be placed over a continuous ground plane. Splitting the ground plane under a connector can cause significant signal integrity and EMI problems.

If the connector must cross a boundary between analog and digital grounds, the split should be placed a short distance away from the connector pins. Alternatively, a stitching capacitor can be used to bridge the split at the connector.

Use Ground Pours in Unused Areas

Copper areas that are not used for signals or components should be filled with a ground pour. This helps to reduce the impedance of the ground connection and provides additional shielding against EMI.

Ground pours also help to equalize copper coverage on the PCB layers, which can prevent warping during manufacturing. However, care must be taken not to create isolated copper areas that could cause resonances or floating voltages.

Route Power and Ground as a Pair

Power traces should always be routed parallel to their corresponding ground traces. This helps to minimize loop area and reduce the inductance of the power distribution network.

On multi-layer boards, power and ground planes should be adjacent to each other in the stackup. This forms a low-impedance, high-frequency bypass capacitor that helps to decouple the power supply.

Isolate Sensitive Circuitry

Sensitive analog or RF circuits should be isolated from noisy digital sections as much as possible. This can be done by placing them on separate ground regions, using split or hybrid ground planes, or even on separate PCBs.

If sensitive circuits must be placed on the same board as noisy ones, they should be physically separated as much as possible. Placing a row of ground vias or a shielding can between the sections can help to contain noise.

Simulate and Test Your Grounding Scheme

Modern PCB design tools include powerful simulation capabilities that can help to validate your grounding scheme before you build a physical board. Tools like Ansys SIwave or Allegro PCB PI can simulate the impedance of your ground network, predict ground bounce, and identify potential EMI issues.

However, simulation is not a substitute for real-world testing. It’s important to measure the actual performance of your grounding scheme on a prototype PCB. Tools like network analyzers, spectrum analyzers, and oscilloscopes can be used to characterize ground impedance, noise levels, and signal integrity.

By following these best practices and carefully simulating and testing your design, you can ensure a robust and effective grounding scheme that will provide reliable performance over the life of your product.

FAQs

Q: What’s the difference between earth ground and chassis ground?

A: Earth ground refers to a connection to the physical earth, usually through the mains wiring in a building. Its primary purpose is safety, to prevent hazardous voltages from appearing on exposed metal parts. Chassis ground is any metal enclosure or shielding that surrounds the circuitry. It may or may not be connected to earth ground, but it provides a shield against EMI and a safety barrier against high voltages.

Q: Do I need to use a ground plane in my PCB design?

A: In most cases, yes. Ground planes offer several important benefits, including lower impedance, better EMI shielding, and improved signal integrity. They have become a standard feature in modern PCB designs. Even simple two-layer boards usually dedicate one layer as a ground plane.

Q: How do I choose between a split ground plane and a hybrid ground plane for my mixed-signal design?

A: Split ground planes offer the best isolation between analog and digital sections, but they can make routing more difficult. Hybrid ground planes have a single ground plane with separate analog and digital regions, connected by a thin trace. They provide some isolation while still allowing traces to cross the boundary. The choice depends on the noise sensitivity of your analog circuits, the routing complexity, and the manufacturing capabilities.

Q: What’s wrong with routing a high-speed signal over a split in the ground plane?

A: A high-speed signal needs a continuous ground reference to maintain signal integrity and prevent EMI. Routing it over a split in the ground plane disrupts the return path, causing the signal to radiate or couple noise into other parts of the circuit. If a high-speed signal must cross a ground split, the split should be bridged with capacitors or the signal should be routed on a different layer.

Q: How many vias should I use for a ground connection?

A: For low-frequency signals, a single via is usually sufficient. However, vias have significant inductance at high frequencies, which can limit their effectiveness. For high-speed signals or decoupling capacitors, it’s best to use multiple vias in parallel to reduce the overall inductance. Two to four vias per connection is typical.

Conclusion

Proper grounding is essential for the reliable operation of any electronic system. In PCBs, grounding serves to provide a low-impedance return path for signals, establish a stable reference voltage, and shield against electromagnetic interference.

There are several types of grounds in a typical PCB, including earth ground, chassis ground, analog ground, digital ground, power ground, and signal ground. Each serves a different purpose, but they must all be tied together properly for the grounding scheme to be effective.

Ground planes are a key feature of modern PCB designs. They provide a low-impedance ground connection and help to route signals and decouple power supplies. The use of ground planes is closely tied to the overall layer stackup of the PCB.

Mixed-signal PCBs present additional grounding challenges, as analog circuits are much more sensitive to digital noise. Split ground planes, hybrid ground planes, and gridded grounds are all strategies that can be used to isolate analog and digital sections while still providing a functional grounding scheme.

Regardless of the specific approach used,

Leave a Reply