What are Flexible PCBs?

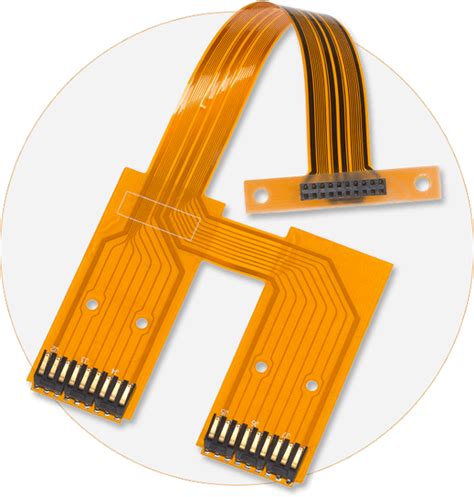

Flexible PCBs, also known as Flex circuits or Flex-PCBs, are a type of printed circuit board that uses a flexible substrate material, typically polyimide or polyester, to interconnect electronic components. Unlike traditional rigid PCBs, Flex PCBs can bend, twist, and fold, allowing for more compact and space-efficient designs. This flexibility enables the creation of electronic devices with unique form factors and improved reliability in applications where motion or vibration is present.

Key Features of Flexible PCBs

-

Flexibility: The most distinguishing feature of Flex PCBs is their ability to bend and flex without compromising the integrity of the circuit. This flexibility allows for the creation of unique product designs and the integration of electronics into tight spaces.

-

Lightweight: Flex PCBs are typically thinner and lighter than their rigid counterparts, making them ideal for applications where weight reduction is critical, such as in aerospace and portable electronics.

-

High Reliability: The flexible nature of Flex PCBs allows them to withstand repeated bending and flexing, making them more resistant to mechanical stress and vibration compared to rigid PCBs.

-

Improved Signal Integrity: Flex PCBs can be designed with controlled impedance and reduced signal loss, enhancing signal integrity in high-speed applications.

-

Cost-effective: In certain applications, Flex PCBs can reduce the overall cost of the electronic assembly by eliminating the need for connectors and cables, simplifying the manufacturing process, and reducing the number of components required.

Manufacturing Process of Flexible PCBs

The manufacturing process of Flex PCBs shares many similarities with that of rigid PCBs, but with some additional steps to accommodate the flexible substrate material. Here’s an overview of the typical manufacturing process:

-

Substrate Preparation: The flexible substrate material, usually polyimide or polyester, is cleaned and treated to ensure proper adhesion of the conductive layers.

-

Copper Lamination: A thin layer of copper is laminated onto the substrate material using heat and pressure. The copper layer serves as the conductive material for the circuit traces.

-

Photolithography: The desired circuit pattern is transferred onto the copper layer using photolithography. A photoresist material is applied to the copper, and the circuit pattern is exposed using UV light through a photomask.

-

Etching: The unwanted copper is removed through an etching process, leaving behind the desired circuit traces.

-

Coverlay Application: A protective coverlay material is applied to the circuit traces to insulate and protect them from damage.

-

Drilling and Cutting: Holes are drilled through the Flex PCB for component mounting and interconnections. The Flex PCB is then cut to its final shape using a laser or die-cutting process.

-

Surface Finishing: Various surface finishes, such as ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative), can be applied to the exposed copper traces to improve solderability and protect against oxidation.

-

Component Assembly: Electronic components are mounted onto the Flex PCB using various methods, such as surface mount technology (SMT) or through-hole mounting.

-

Testing and Inspection: The assembled Flex PCB undergoes rigorous testing and inspection to ensure proper functionality and adherence to quality standards.

Flex PCB Stack-Up

The stack-up of a Flex PCB refers to the arrangement of conductive layers and insulating materials that make up the circuit board. The most common Flex PCB stack-ups include:

| Stack-up Type | Description |

|---|---|

| Single-sided | A single conductive layer on one side of the flexible substrate |

| Double-sided | Conductive layers on both sides of the flexible substrate |

| Multi-layer | Multiple conductive layers separated by insulating layers |

| Rigid-Flex | A combination of rigid and flexible sections in a single PCB |

The choice of stack-up depends on the complexity of the circuit design, the required flexibility, and the intended application.

Applications of Flexible PCBs

Flex PCBs find applications across a wide range of industries due to their unique properties and advantages over rigid PCBs. Some of the most common applications include:

Consumer Electronics

Flex PCBs are extensively used in consumer electronics, such as smartphones, tablets, wearables, and smart home devices. Their flexibility allows for the creation of slim, compact, and lightweight designs, while also enabling the integration of electronics into curved or irregular shapes.

Medical Devices

The medical industry has embraced Flex PCBs for their reliability, biocompatibility, and ability to conform to the human body. Flex PCBs are used in medical devices such as hearing aids, pacemakers, insulin pumps, and wearable health monitoring systems.

Automotive Electronics

In the automotive industry, Flex PCBs are used in various applications, including instrument clusters, infotainment systems, and advanced driver assistance systems (ADAS). Their resistance to vibration and ability to fit into tight spaces make them well-suited for the harsh automotive environment.

Aerospace and Defense

Flex PCBs are used in aerospace and defense applications where weight reduction, space savings, and high reliability are critical. They are found in avionics systems, satellite communications, and military equipment.

Industrial Automation

Industrial automation systems benefit from the use of Flex PCBs due to their ability to withstand harsh environmental conditions, such as extreme temperatures, humidity, and chemical exposure. Flex PCBs are used in sensors, actuators, and control systems in industrial settings.

Future Trends in Flexible PCB Technology

As the demand for smaller, lighter, and more flexible electronic devices continues to grow, the Flex PCB industry is expected to witness significant advancements in the coming years. Some of the future trends in Flex PCB technology include:

-

Increased Adoption of High-Density Interconnects (HDI): HDI technology allows for the creation of finer pitch traces and smaller vias, enabling higher component density and improved signal integrity in Flex PCBs.

-

Integration of Active Components: The integration of active components, such as IC chips and sensors, directly onto the Flex PCB substrate is expected to become more prevalent, leading to further miniaturization and improved performance.

-

Advanced Materials: The development of new flexible substrate materials with enhanced properties, such as higher temperature resistance, improved electrical performance, and better biocompatibility, will expand the application range of Flex PCBs.

-

3D Printing: The use of 3D printing technology for the fabrication of Flex PCBs is an emerging trend that could potentially reduce manufacturing costs and lead times while enabling more complex and customized designs.

-

Wearable Electronics: As the wearable technology market continues to grow, Flex PCBs will play a crucial role in enabling the development of comfortable, lightweight, and conformable wearable devices.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between a Flex PCB and a rigid PCB?

A: The main difference between a Flex PCB and a rigid PCB is the substrate material. Flex PCBs use a flexible substrate, such as polyimide or polyester, while rigid PCBs use a rigid substrate, typically FR-4. This flexibility allows Flex PCBs to bend, fold, and conform to various shapes, whereas rigid PCBs maintain a fixed, rigid structure. -

Q: Can Flex PCBs be used in high-temperature applications?

A: Yes, Flex PCBs can be designed to withstand high temperatures by using appropriate substrate materials and components. Polyimide, a common Flex PCB substrate, has a high glass transition temperature and can maintain its mechanical and electrical properties at elevated temperatures. -

Q: Are Flex PCBs more expensive than rigid PCBs?

A: In general, Flex PCBs tend to be more expensive than rigid PCBs due to the specialized materials and manufacturing processes involved. However, in certain applications, the use of Flex PCBs can lead to overall cost savings by reducing the number of components, simplifying assembly, and improving reliability. -

Q: How do I choose the right Flex PCB stack-up for my application?

A: The choice of Flex PCB stack-up depends on several factors, including the complexity of the circuit design, the required flexibility, and the intended application. Single-sided and double-sided Flex PCBs are suitable for simpler designs, while multi-layer and rigid-flex PCBs are used for more complex circuits that require higher component density and improved signal integrity. Consulting with a Flex PCB manufacturer or an experienced PCB designer can help in selecting the most appropriate stack-up for your specific application. -

Q: What are the challenges in designing Flex PCBs compared to rigid PCBs?

A: Designing Flex PCBs presents some unique challenges compared to rigid PCBs. These include considering the mechanical stresses on the circuit during flexing, ensuring proper bend radius and bend relief, and accounting for the differences in thermal expansion between the flexible substrate and the components. Additionally, signal integrity and EMI/EMC considerations may require special attention in Flex PCB designs. Designers must also be mindful of the manufacturing limitations and work closely with the Flex PCB manufacturer to ensure the design is producible and reliable.

In conclusion, Flexible PCBs have emerged as a game-changing technology in the world of electronics, enabling the creation of innovative, compact, and reliable electronic devices. With their unique capabilities and advantages over traditional rigid PCBs, Flex PCBs have found applications across a wide range of industries, from consumer electronics and medical devices to automotive and aerospace systems. As the demand for smaller, lighter, and more flexible electronics continues to grow, the Flex PCB industry is poised for significant advancements in the coming years. By understanding the capabilities, manufacturing processes, and design considerations of Flex PCBs, engineers and product designers can leverage this versatile technology to create the next generation of electronic devices that push the boundaries of form and function.

Leave a Reply