Introduction to Rogers TMM 6

Rogers TMM 6 is a ceramic-filled, thermoset laminate material that is designed for high frequency, high performance printed circuit boards (PCBs). It features excellent dielectric properties for applications up to 40 GHz and beyond.

Some key features of Rogers TMM 6 laminate include:

- Stable dielectric constant of 6.15 across a wide frequency range

- Low loss tangent of 0.0035 at 10 GHz

- Low Z-axis CTE for reliability

- High thermal conductivity for heat dissipation

- Compatible with common PCB processing methods

With its superior electrical and thermal performance, Rogers TMM 6 enables the design of advanced RF/microwave PCBs for applications such as 5G infrastructure, radar systems, satellite communications, test and measurement equipment, and more.

Rogers TMM 6 Material Properties

The material properties of Rogers TMM 6 that make it well-suited for high frequency applications are outlined below:

Dielectric Constant

- Dielectric constant (Dk): 6.15 ± 0.15

- Extremely stable across temperature and frequency range

- Enables tightly controlled impedance and wavelength for controlled signal propagation

Loss Tangent

- Loss tangent: 0.0035 at 10 GHz

- Low loss for high frequency efficiency and performance

Coefficient of Thermal Expansion (CTE)

- X and Y CTE: 30-35 ppm/°C (x,y)

- Z CTE: 15-20 ppm/°C (z)

- Matched CTE in x, y, and z directions

- Provides excellent dimensional stability during thermal excursions

Thermal Conductivity

- 0.92 W/mK

- Allows efficient heat transfer away from components

Dielectric Strength

- 700 V/mil

- High breakdown voltage enables thinner dielectric layers

Moisture Absorption

- <0.2%

- Resists absorbed moisture to prevent signal loss

Key Material Properties Summary

| Property | Value |

|---|---|

| Dielectric Constant | 6.15 ± 0.15 |

| Loss Tangent | 0.0035 at 10 GHz |

| X,Y CTE | 30-35 ppm/°C |

| Z CTE | 15-20 ppm/°C |

| Thermal Conductivity | 0.92 W/mK |

| Dielectric Strength | >700 V/mil |

| Moisture Absorption | <0.2% |

Rogers TMM 6 Laminate Copper Cladding

Rogers TMM 6 laminates are available with different copper foil cladding options:

- Standard 1⁄2 oz (18 μm) or 1 oz (35 μm) electrodeposited copper foils

- Reverse treat foils for improved adhesion

- Low profile copper foil to minimize conductor losses at higher frequencies

Heavier copper weights can also be specified for applications requiring high current carrying capacity.

The selection of copper foil type and weight impacts signal loss, current carrying capability, and manufacturability.

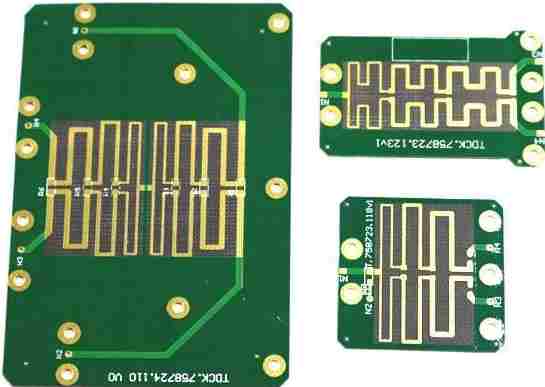

PCB Design with Rogers TMM 6

Rogers TMM 6 laminates enable the design of advanced RF PCBs, but require careful layout and tuning to achieve peak electrical performance. Here are some key design guidelines:

Controlled Impedance

- Match PCB trace impedance to RF system impedance (typically 50 Ω or 75 Ω)

- This requires management of trace width, dielectric thickness, and dielectric constant

- Use impedance calculators to determine exact trace geometry

Minimize Conductor Losses

- Use thicker copper weights where possible

- Minimize number of vias and avoid small drill sizes where practical

- Use low-loss PCB finishes such as immersion silver

Maintain Signal Integrity

- Provide proper component layout and isolation for sensitive RF traces

- Watch for impedance mismatches at transitions between traces and components

- Use ground vias for isolation and preventing unwanted signal coupling

Thermal Management

- Ensure adequate heat sinking, thermal vias, and/or backside metallization

- Consider thermal impacts on material properties and electrical performance

Proper modeling, simulation, and testing helps validate RF PCB performance to meet application needs prior to full production.

PCB Fabrication with Rogers TMM 6

Rogers TMM 6 can be fabricated into PCBs and circuits using standard PCB methods. Here are some guidelines for reliable processing:

Imaging and Etching

- Compatible with most liquid photo resists and methods

- Can be etched in ammoniacal or cupric chloride chemistries

Hole Drilling

- Use standard mechanical or laser drilling

- Laser drilling provides small vias while minimizing smear

Plating and Outerlayer Imaging

- Electroless copper and direct metallization plating are compatible

- Roller coating resists preferred for uniform and void-free plating

Solder Mask

- LPI solder masks recommended for accurate registration and tenting

Final Finishes

- Immersion silver, immersion tin, ENIG, HASL are compatible final finishes

Rogers Corp provides additional guidelines for each process step to optimize fabrication with TMM 6 material.

Rogers TMM 6 Material Availability

Rogers TMM 6 laminates are available in sheets and panels form using the TR/TMM6 material designation. Some standard offerings include:

| Material | Description |

|---|---|

| TR/TMM6(0050) | 0.005” (0.127mm) dielectric |

| TR/TMM6(0100) | 0.010” (0.254mm) dielectric |

| TR/TMM6(0200) | 0.020” (0.508mm) dielectric |

| TR/TMM10(0200) | 0.020” (0.508mm) dielectric |

- Standard panel sizes up to 18” x 24” or 24” x 18”

- Sheet stock available

- Prepregs available for multilayer boards with TMM6

- Other dielectric thicknesses, copper weights, and claddings available upon request

The combination of stock sheets and quick-turn fabrication services enable fast prototyping and short production lead times with Rogers TMM 6 material.

Rogers TMM 6 Laminate Applications

The stable electrical performance and high frequency capabilities of Rogers TMM 6 make it a material of choice for many advanced RF PCB applications including:

5G Infrastructure

- 5G base stations and massive MIMO antennas

- Front-haul and back-haul equipment

- Test and measurement

Military and Aerospace

- Radar and electronic warfare systems

- Satellite communications

- Avionics equipment

Wireless Testing

- Wireless test fixtures

- Production testing

- R&D characterization

Microwave Systems

- Point-to-point radios

- Microwave radio heads

- VSAT and communications on the move

Rogers TMM 6 Material Considerations

While Rogers TMM 6 provides excellent high frequency laminate performance, there are some considerations when selecting it for an application:

- Higher material cost than FR-4 laminates

- More difficult to hand-solder due to high Tg (>280C)

- Requires tight process controls to achieve consistency

- Lead time may be longer than standard materials

- Special handling required to prevent mechanical or moisture damage

For many applications, the superior electrical performance of Rogers TMM 6 outweighs these considerations. But all design and manufacturing factors should be evaluated when selecting a circuit material.

Frequently Asked Questions

What is the shelf life of Rogers TMM 6 material?

The shelf life of Rogers TMM 6 material is 1 year from the date of shipment when stored in a cool, dry environment and in unopened packaging. The material should also be kept sealed and dessicated during storage to prevent moisture absorption.

What are the bonding parameters for multilayer boards using Rogers TMM 6 prepreg?

Rogers recommends lamination pressure of 200 psi for bonding multilayer boards with TMM 6 prepreg. The recommended lamination temperature cycle is:

- Heat to 190°C at a 3-5°C/min ramp rate

- Hold at 190°C for 1 hour

- Heat to 250°C at a 3-5°C/min ramp rate

- Hold at 250°C for 1 hour

- Cool to below 60°C at 4-6°C/min before removing pressure

The high lamination temperature helps ensure full curing of the prepreg resin.

Can Rogers TMM 6 be used for microwave hybrid circuits?

Yes, Rogers TMM 6 is an excellent choice of substrate for microwave hybrid circuits. Its stable dielectric constant facilitates precise microwave circuit design, while its high frequency performance supports operation well into microwave bands. The ceramic filler offers improved thermal conductivity to dissipate heat from power circuits.

What chemical etchants can be used to fabricate PCBs with Rogers TMM 6?

Ammoniacal and cupric chloride etchants are commonly used to etch Rogers TMM 6 boards. Cupric chloride will provide a faster etch rate. Peracetic acid can also be used for a “swell and etch” process. Good process control is needed to achieve desired edge profiles and minimize undercutting.

Is Rogers TMM 6 material suitable for high power RF printed circuit boards?

Yes, Rogers TMM 6 can be an appropriate choice for high power RF PCBs due to its favorable thermal conductivity, dielectric strength, and temperature resistance. Thicker dielectrics and heavier copper weights help manage thermal loads and current capacity. The material is routinely used for high power amplifiers and other microwave circuits requiring robust electrical and thermal performance.

Leave a Reply