What is a Metal-Core PCB?

A metal-core printed circuit board (MCPCB) is a specialized type of PCB that uses a metal base instead of the standard FR-4 fiberglass material. The metal core, typically made of aluminum, provides excellent thermal conductivity, allowing heat to dissipate quickly and efficiently from the mounted components, such as high-power LEDs.

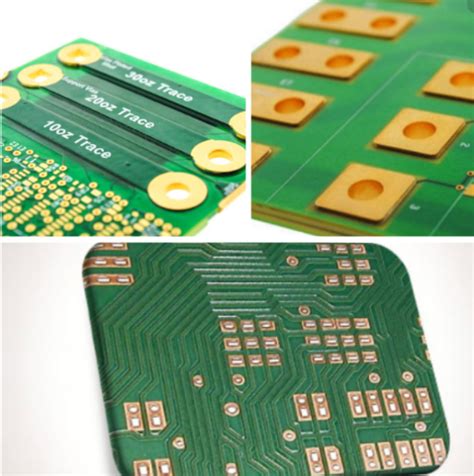

MCPCBs consist of three layers:

- A thin dielectric layer

- A metal core (usually aluminum)

- A copper circuit layer

The dielectric layer electrically isolates the copper circuit layer from the metal core while allowing efficient heat transfer.

Advantages of using Metal-Core PCBs for LED applications

Superior thermal management

One of the primary reasons to choose a metal-core PCB over a standard PCB for LED-based products is its superior thermal management capabilities. LEDs generate a significant amount of heat, which can negatively impact their performance, lifespan, and color consistency. By using an MCPCB, the heat generated by the LEDs is efficiently dissipated through the metal core, maintaining optimal operating temperatures.

The thermal conductivity of aluminum, the most common metal core material, is around 205 W/mK, while FR-4, the standard PCB material, has a thermal conductivity of only 0.3 W/mK. This substantial difference in thermal conductivity allows MCPCBs to dissipate heat up to 8-10 times more effectively than standard PCBs.

Improved LED performance and longevity

By maintaining a lower operating temperature, MCPCBs enable LEDs to perform at their best. High temperatures can cause a decrease in LED light output, shifts in color temperature, and reduced lifespan. With proper thermal management provided by MCPCBs, LEDs can maintain their optimal light output, color consistency, and longer lifespans.

LED Lifespan Comparison:

| PCB Type | Operating Temperature | Estimated Lifespan |

|———-|———————-|——————-|

| Standard PCB | 85°C | 50,000 hours |

| Metal-Core PCB | 60°C | 100,000 hours |

Note: Lifespan estimates are based on average values and can vary depending on the specific LED and operating conditions.

Design flexibility and cost-effectiveness

MCPCBs offer design flexibility by allowing for the creation of custom thermal management solutions tailored to specific LED applications. The metal core can be shaped and sized according to the design requirements, enabling more compact and efficient layouts.

Moreover, using MCPCBs can be cost-effective in the long run. While the initial cost of an MCPCB may be higher than a standard PCB, the improved thermal management leads to increased LED lifespan and reduced maintenance costs. This is particularly valuable in applications where LED replacements are difficult or costly, such as in automotive lighting or industrial equipment.

Applications of Metal-Core PCBs in LED-based products

Automotive lighting

MCPCBs are widely used in automotive lighting applications, such as headlights, taillights, and interior lighting. The harsh operating conditions in vehicles, including high temperatures and vibrations, make efficient thermal management crucial. MCPCBs ensure that the LEDs perform reliably and maintain their light output and color consistency throughout the vehicle’s lifespan.

Industrial lighting

Industrial environments often require high-power LED lighting solutions that can withstand demanding conditions. MCPCBs are ideal for industrial lighting applications, such as factory floor illumination, warehouse lighting, and outdoor area lighting. The superior thermal management provided by MCPCBs ensures that the LEDs can operate continuously at high power levels without overheating or experiencing premature failure.

Architectural lighting

Architectural lighting often involves compact, high-power LED fixtures that require efficient thermal management to maintain optimal performance and aesthetics. MCPCBs allow for the creation of sleek, low-profile designs that can be seamlessly integrated into various architectural elements, such as walls, ceilings, and facades. The excellent heat dissipation properties of MCPCBs ensure that the LEDs maintain their light output and color consistency, enhancing the overall visual appeal of the architectural space.

Medical and scientific instruments

LED-based medical and scientific instruments, such as microscope illuminators, endoscopes, and dental curing lights, require reliable and consistent light output. MCPCBs provide the necessary thermal management to ensure that the LEDs perform optimally and maintain their output stability over time. Additionally, the compact designs made possible by MCPCBs allow for the creation of smaller, more ergonomic instruments that are easier to handle and maneuver.

Choosing the right Metal-Core PCB for your LED application

When selecting an MCPCB for your LED application, consider the following factors:

-

Thermal requirements: Determine the amount of heat generated by your LEDs and choose an MCPCB with the appropriate thermal conductivity and heat dissipation capabilities.

-

Dielectric layer thickness: A thinner dielectric layer allows for better thermal conductivity but may increase the risk of electrical shorts. Strike a balance between thermal performance and electrical safety.

-

Metal core thickness: Thicker metal cores provide better heat spreading but may increase the overall thickness of the PCB. Consider the available space in your design when choosing the metal core thickness.

-

Surface finish: Select a surface finish that enhances thermal conductivity and solderability, such as Electroless Nickel Immersion Gold (ENIG) or Immersion Silver.

-

Manufacturing process: Ensure that your MCPCB manufacturer has experience in producing high-quality MCPCBs and can meet your specific design requirements and tolerances.

FAQ

1. Are metal-core PCBs more expensive than standard PCBs?

Yes, metal-core PCBs are generally more expensive than standard PCBs due to the additional materials and manufacturing processes involved. However, the long-term benefits of improved thermal management, increased LED lifespan, and reduced maintenance costs often outweigh the initial investment.

2. Can metal-core PCBs be used for applications other than LEDs?

While metal-core PCBs are primarily used in LED applications, they can also be beneficial in other applications that require efficient thermal management, such as power electronics, high-performance processors, and radio frequency (RF) devices.

3. What are the most common metal core materials used in MCPCBs?

Aluminum is the most common metal core material used in MCPCBs due to its excellent thermal conductivity, lightweight properties, and cost-effectiveness. Other materials, such as copper and copper-molybdenum alloys, may be used in applications that require even higher thermal conductivity or specific mechanical properties.

4. How do I select the appropriate dielectric layer thickness for my MCPCB?

The dielectric layer thickness should be chosen based on the specific requirements of your application. Thinner dielectric layers provide better thermal conductivity but may increase the risk of electrical shorts. Consult with your MCPCB manufacturer to determine the optimal dielectric layer thickness for your design, considering factors such as voltage requirements, thermal performance, and manufacturing feasibility.

5. Can metal-core PCBs be used in flexible circuit applications?

While metal-core PCBs are typically rigid, there are some specialized flexible MCPCBs available that incorporate a thin, flexible metal core. These flexible MCPCBs offer the benefits of efficient thermal management in applications that require a degree of flexibility, such as wearable electronics or compact, conformable LED lighting solutions.

Conclusion

Metal-core PCBs offer significant advantages over standard PCBs in LED-based products, primarily due to their superior thermal management capabilities. By efficiently dissipating heat away from the LEDs, MCPCBs enable improved LED performance, color consistency, and longevity. These benefits make MCPCBs an ideal choice for various LED applications, including automotive lighting, industrial lighting, architectural lighting, and medical and scientific instruments.

When selecting an MCPCB for your LED application, consider factors such as thermal requirements, dielectric layer thickness, metal core thickness, surface finish, and manufacturing process. By choosing the right MCPCB and working with an experienced manufacturer, you can create high-performance, reliable, and cost-effective LED-based products that meet the demanding requirements of today’s market.

Leave a Reply