What is FR-4 Material?

FR-4 (Flame Retardant 4) is a glass-reinforced epoxy laminate material widely used in the manufacturing of PCBs. It is a composite material consisting of woven fiberglass cloth impregnated with an epoxy resin binder. FR-4 is known for its excellent mechanical and electrical properties, making it a popular choice for a wide range of electronic applications.

Composition and Structure

FR-4 is made by layering sheets of woven fiberglass cloth and impregnating them with an epoxy resin. The fiberglass provides mechanical strength and dimensional stability, while the epoxy resin acts as a binder and offers insulation properties. The number of layers and the thickness of the FR-4 laminate can vary depending on the specific requirements of the PCB.

Properties of FR-4

FR-4 exhibits several desirable properties that make it suitable for PCB Fabrication:

-

Mechanical Strength: FR-4 has good mechanical strength and rigidity, allowing it to withstand the stresses and strains encountered during the manufacturing process and in the final application.

-

Electrical Insulation: The epoxy resin in FR-4 provides excellent electrical insulation, preventing short circuits and ensuring proper Signal Integrity.

-

Flame Retardancy: As the name suggests, FR-4 is flame retardant, meeting the UL94 V-0 flammability rating. This property is crucial for ensuring the safety of electronic devices.

-

Thermal Stability: FR-4 has a glass transition temperature (Tg) of around 130°C to 140°C, providing good thermal stability for most standard PCB applications.

-

Moisture Resistance: FR-4 offers decent moisture resistance, making it suitable for use in various environmental conditions.

Applications of FR-4

FR-4 is a versatile material and finds applications in a wide range of industries and products:

- Consumer electronics: Smartphones, laptops, televisions, and home appliances

- Automotive electronics: Engine control units, infotainment systems, and sensors

- Industrial electronics: Control systems, power supplies, and automation equipment

- Telecommunications: Routers, switches, and network infrastructure

- Medical devices: Diagnostic equipment, monitoring systems, and implantable devices

What is Rogers Material?

Rogers material, also known as Rogers laminate, is a specialty substrate material designed for high-frequency and high-speed applications. Rogers offers a range of materials with varying properties to cater to specific requirements in RF (Radio Frequency) and microwave circuits.

Composition and Structure

Rogers materials are typically composed of a ceramic-filled PTFE (polytetrafluoroethylene) or a hydrocarbon-ceramic composite. These materials provide a low dielectric constant (Dk) and a low dissipation factor (Df), which are essential for high-frequency performance. The ceramic filler helps to control the dielectric constant and improve the thermal conductivity of the material.

Properties of Rogers Material

Rogers materials exhibit several unique properties that make them ideal for high-frequency applications:

-

Low Dielectric Constant (Dk): Rogers materials have a lower dielectric constant compared to FR-4, typically ranging from 2.2 to 10.2. A lower Dk results in faster signal propagation and reduced signal loss.

-

Low Dissipation Factor (Df): The dissipation factor, also known as the loss tangent, is a measure of the energy loss in the material. Rogers materials have a low Df, typically in the range of 0.0009 to 0.002, which minimizes signal attenuation and maintains signal integrity at high frequencies.

-

Controlled Dielectric Constant: Rogers materials offer a consistent dielectric constant across a wide frequency range, ensuring predictable performance and minimizing signal distortion.

-

Thermal Conductivity: Some Rogers materials, such as RO4003C and RT/duroid 6035HTC, have enhanced thermal conductivity, allowing for better heat dissipation in high-power applications.

-

Dimensional Stability: Rogers materials maintain their dimensional stability over a wide temperature range, ensuring consistent performance in demanding environmental conditions.

Applications of Rogers Material

Rogers materials are primarily used in high-frequency and high-speed applications where signal integrity and low loss are critical:

- Wireless Communication: Base stations, antennas, and RF modules

- Radar Systems: Automotive radar, aerospace and defense radar applications

- Satellite Communication: Satellite transceivers and ground stations

- High-Speed Digital: High-speed digital circuits, high-bandwidth data transmission

- Microwave and Millimeter-Wave: Microwave circuits, millimeter-wave radar, and imaging systems

FR4 vs Rogers: Key Differences

Now that we have a basic understanding of FR-4 and Rogers materials let’s compare their key differences:

| Property | FR-4 | Rogers |

|---|---|---|

| Dielectric Constant (Dk) | 4.2 to 4.6 | 2.2 to 10.2 |

| Dissipation Factor (Df) | 0.02 to 0.03 | 0.0009 to 0.002 |

| Thermal Conductivity | Low | Varies (Some have enhanced thermal conductivity) |

| Moisture Absorption | Higher | Lower |

| Cost | Lower | Higher |

| Frequency Range | Suitable for low to mid frequencies | Suitable for high frequencies and high-speed applications |

Dielectric Constant and Dissipation Factor

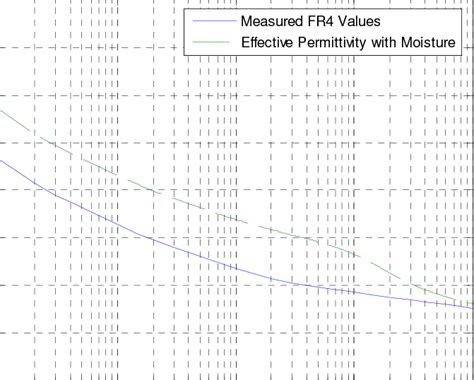

One of the main differences between FR-4 and Rogers materials is their dielectric constant (Dk) and dissipation factor (Df). FR-4 has a higher Dk, typically ranging from 4.2 to 4.6, while Rogers materials have a lower Dk, ranging from 2.2 to 10.2. A lower Dk results in faster signal propagation and reduced signal loss, making Rogers materials more suitable for high-frequency applications.

Similarly, FR-4 has a higher Df, ranging from 0.02 to 0.03, while Rogers materials have a lower Df, typically in the range of 0.0009 to 0.002. A lower Df minimizes signal attenuation and maintains signal integrity at high frequencies.

Thermal Conductivity

Thermal conductivity is another area where FR-4 and Rogers materials differ. FR-4 has relatively low thermal conductivity, which can limit its use in high-power applications where heat dissipation is critical. On the other hand, some Rogers materials, such as RO4003C and RT/duroid 6035HTC, have enhanced thermal conductivity, making them suitable for applications that generate significant heat.

Moisture Absorption

FR-4 has higher moisture absorption compared to Rogers materials. Moisture absorption can lead to changes in the dielectric constant and affect the performance of the PCB. Rogers materials have lower moisture absorption, making them more stable in humid environments.

Cost

FR-4 is generally less expensive than Rogers materials. The higher cost of Rogers materials is due to their specialized composition and superior high-frequency performance. The choice between FR-4 and Rogers often depends on the specific requirements of the application and the budget constraints.

Frequency Range

FR-4 is suitable for low to mid-frequency applications, typically up to a few gigahertz. Beyond that, the higher dielectric constant and dissipation factor of FR-4 can lead to signal loss and degradation. Rogers materials, with their lower Dk and Df, are designed for high-frequency and high-speed applications, offering superior performance in the gigahertz and even millimeter-wave range.

Choosing Between FR-4 and Rogers

When deciding between FR-4 and Rogers materials for your PCB, consider the following factors:

-

Frequency Range: If your application operates at high frequencies or requires high-speed signal transmission, Rogers materials are the preferred choice. FR-4 is suitable for lower frequency applications.

-

Signal Integrity: For applications where signal integrity is critical, such as in wireless communication or radar systems, Rogers materials provide lower signal loss and better signal quality.

-

Power Handling: If your application involves high-power transmission or generates significant heat, Rogers materials with enhanced thermal conductivity can help dissipate heat more effectively.

-

Environmental Conditions: If your PCB will be exposed to humid environments, Rogers materials with lower moisture absorption can provide better stability and performance.

-

Cost: FR-4 is a more cost-effective option for general-purpose PCBs. If your application demands the superior performance of Rogers materials, be prepared to invest in the higher cost.

Conclusion

FR-4 and Rogers materials are both widely used in PCB fabrication, but they cater to different application requirements. FR-4 is a versatile and cost-effective choice for general-purpose PCBs operating at lower frequencies. Rogers materials, on the other hand, are specialized substrates designed for high-frequency and high-speed applications, offering lower dielectric constant, lower dissipation factor, and better signal integrity.

When choosing between FR-4 and Rogers, consider the frequency range, signal integrity requirements, power handling, environmental conditions, and cost of your application. By understanding the differences between these materials and their suitability for specific applications, you can make an informed decision and ensure optimal performance for your PCB project.

Frequently Asked Questions (FAQ)

- Can I use FR-4 for high-frequency applications?

-

While FR-4 can be used for some high-frequency applications, it may not provide the same level of performance as Rogers materials. FR-4 has a higher dielectric constant and dissipation factor, which can lead to signal loss and degradation at higher frequencies. For optimal high-frequency performance, Rogers materials are recommended.

-

Are Rogers materials more expensive than FR-4?

-

Yes, Rogers materials are generally more expensive than FR-4. The higher cost is due to the specialized composition and superior high-frequency performance of Rogers materials. However, the cost difference may be justified for applications that require the enhanced properties and performance offered by Rogers materials.

-

Can I mix FR-4 and Rogers materials on the same PCB?

-

Yes, it is possible to use both FR-4 and Rogers materials on the same PCB. This approach is called a hybrid PCB, where FR-4 is used for the general-purpose circuitry, and Rogers materials are used for the high-frequency or high-speed sections. However, designing a hybrid PCB requires careful consideration of the material transitions and signal integrity.

-

How do I select the right Rogers material for my application?

-

Rogers offers a range of materials with varying properties to cater to different application requirements. The selection of the right Rogers material depends on factors such as the frequency range, dielectric constant, dissipation factor, thermal conductivity, and cost. Consult the Rogers material datasheets and work with your PCB manufacturer to determine the most suitable material for your specific application.

-

Are there any other high-frequency PCB materials besides Rogers?

- Yes, there are other high-frequency PCB materials available in the market. Some examples include Isola, Taconic, and Arlon materials. These materials offer similar properties to Rogers materials, such as low dielectric constant and low dissipation factor, and are suitable for high-frequency and high-speed applications. However, Rogers materials are widely recognized and trusted in the industry for their consistent performance and reliability.

Leave a Reply