Introduction to PCB Files

A PCB file, short for Printed Circuit Board file, is a digital file format used in the design and manufacturing of electronic circuits. These files contain all the necessary information required to fabricate a physical PCB, including the layout of copper traces, component placement, drill holes, and various layers that make up the complete circuit board.

PCB files are essential in the electronic design automation (EDA) process, as they bridge the gap between the schematic design and the actual production of the PCB. They enable designers to create complex circuits with precision and accuracy while also allowing manufacturers to streamline the production process.

Key Components of a PCB File

-

Copper Traces: PCB files define the layout and routing of copper traces that connect various components on the board. These traces are designed to carry electrical signals between components.

-

Component Placement: The file specifies the exact location and orientation of each component on the PCB, ensuring proper connections and functionality.

-

Drill Holes: PCB files include information about the location and size of drill holes required for mounting components and creating electrical connections between layers.

-

Layers: A PCB can consist of multiple layers, each serving a specific purpose. The PCB file defines the arrangement and composition of these layers, which can include copper, insulation, and solder mask.

Common PCB File Formats

There are several file formats used to represent PCB designs, each with its own characteristics and advantages. Some of the most common PCB file formats include:

1. Gerber Files (.gbr)

Gerber files are the most widely used format for PCB manufacturing. They are ASCII text files that describe the layout of each layer in the PCB, including copper traces, solder mask, silkscreen, and drill holes. Gerber files are named after their creator, H. Joseph Gerber, who developed the format in the 1960s.

Advantages of Gerber files:

– Universally accepted by PCB manufacturers

– Simple and reliable format

– Can be easily viewed and edited using Gerber viewers

2. ODB++ Files (.tgz)

ODB++, or Open Database++, is a more modern and intelligent format compared to Gerber files. It is a compressed archive that contains all the necessary information for PCB fabrication and assembly in a single, unified database. ODB++ files include not only the layer data but also the bill of materials (BOM), component placement, and netlist information.

Advantages of ODB++ files:

– Comprehensive and self-contained format

– Supports advanced features like embedded components and sequential lamination

– Enables better communication between design and manufacturing teams

3. IPC-2581 Files (.xml)

IPC-2581 is an open, vendor-neutral format for exchanging PCB design data. It is based on XML and provides a standardized way to represent PCB layout, stackup, materials, and other manufacturing information. IPC-2581 files are human-readable and can be easily parsed by software tools.

Advantages of IPC-2581 files:

– Standardized and vendor-neutral format

– Supports advanced manufacturing capabilities

– Facilitates data exchange between different EDA tools and manufacturing systems

PCB Design and Manufacturing Workflow

The PCB design and manufacturing process typically involves the following steps:

-

Schematic Design: The circuit is designed using EDA software, which captures the electrical connections and component properties.

-

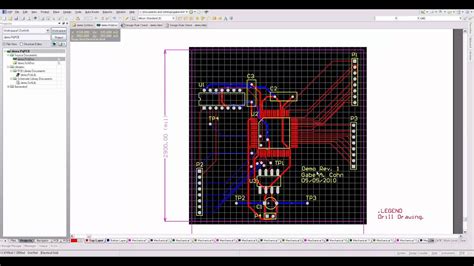

PCB Layout: The schematic is translated into a physical layout, where components are placed and traces are routed on the PCB.

-

Design Rule Check (DRC): The layout is checked against a set of design rules to ensure manufacturability and functionality.

-

PCB File Generation: Once the layout is finalized, the PCB file (e.g., Gerber or ODB++) is generated, containing all the necessary information for manufacturing.

-

Fabrication: The PCB manufacturer uses the PCB file to fabricate the physical board, including etching copper traces, drilling holes, and applying solder mask and silkscreen.

-

Assembly: Components are placed and soldered onto the fabricated PCB according to the component placement information in the PCB file.

-

Testing and Inspection: The assembled PCB undergoes various tests and inspections to verify its functionality and quality.

The table below summarizes the key steps in the PCB design and manufacturing workflow:

| Step | Description |

|---|---|

| Schematic Design | Capturing the electrical connections and component properties |

| PCB Layout | Translating the schematic into a physical layout |

| Design Rule Check | Verifying the layout against manufacturing and functionality rules |

| PCB File Generation | Creating the PCB file (e.g., Gerber or ODB++) for manufacturing |

| Fabrication | Manufacturing the physical PCB based on the PCB file |

| Assembly | Placing and soldering components onto the fabricated PCB |

| Testing and Inspection | Verifying the functionality and quality of the assembled PCB |

Importance of PCB Files in Electronics Industry

PCB files play a crucial role in the electronics industry, enabling the design and manufacture of complex circuits with high precision and reliability. They provide a standardized way to communicate design intent between different stakeholders, including designers, manufacturers, and assembly houses.

Some of the key benefits of using PCB files include:

-

Design Precision: PCB files allow designers to create intricate layouts with tight tolerances, ensuring the proper functioning of the circuit.

-

Manufacturing Efficiency: By providing a complete and unambiguous representation of the PCB, these files enable manufacturers to streamline their processes and reduce errors.

-

Collaboration: PCB files facilitate collaboration between design teams, manufacturers, and clients, as they provide a common language for exchanging design data.

-

Revision Control: PCB files can be easily versioned and tracked, allowing for better management of design changes and updates.

-

Automation: Many aspects of the PCB design and manufacturing process can be automated using PCB files, reducing manual effort and increasing productivity.

As the electronics industry continues to evolve, with increasing demand for smaller, faster, and more complex circuits, the importance of PCB files will only grow. Designers and manufacturers who stay up-to-date with the latest file formats and best practices will be well-positioned to meet the challenges of the future.

Frequently Asked Questions (FAQ)

-

What software is used to create PCB files?

PCB files are typically created using electronic design automation (EDA) software, such as Altium Designer, KiCad, Eagle, or OrCAD. These tools provide a user-friendly interface for designing schematics and layouts, and generating the necessary manufacturing files. -

Can PCB files be edited after they are generated?

Yes, PCB files can be edited using specialized software tools. For example, Gerber files can be viewed and edited using Gerber viewers and editors, while ODB++ files can be modified using tools provided by the format’s developers. However, it is important to exercise caution when editing PCB files, as changes can affect the manufacturability and functionality of the final board. -

How do I choose the right PCB file format for my project?

The choice of PCB file format depends on several factors, including the complexity of the design, the manufacturing capabilities of your chosen fabrication house, and the level of collaboration required between design and manufacturing teams. Gerber files are the most widely supported and are suitable for most standard PCB designs. ODB++ and IPC-2581 offer additional benefits for more complex designs and advanced manufacturing processes. -

What information should I provide to the PCB manufacturer along with the PCB files?

In addition to the PCB files themselves, it is important to provide the manufacturer with a comprehensive fabrication package, which may include: - Bill of Materials (BOM): A list of all components used in the design, including part numbers, quantities, and specifications.

- Assembly Drawings: Detailed drawings showing the placement and orientation of components on the PCB.

-

Special Instructions: Any specific requirements or considerations for the manufacturing process, such as surface finishes, testing, or packaging.

-

How can I ensure the quality and reliability of my PCB design?

To ensure the quality and reliability of your PCB design, follow these best practices: - Adhere to industry standards and design guidelines, such as IPC standards for PCB design and manufacturing.

- Perform thorough design rule checks (DRC) to verify that your layout meets manufacturing constraints and functional requirements.

- Collaborate closely with your PCB manufacturer to ensure that your design is optimized for their specific processes and capabilities.

- Conduct rigorous testing and inspection of the fabricated and assembled PCBs to identify and address any issues early in the production cycle.

By understanding the importance of PCB files and following best practices for design and manufacturing, you can ensure the successful realization of your electronic projects.

Conclusion

PCB files are the cornerstone of the electronic design and manufacturing process, enabling the creation of complex, high-performance circuits with precision and reliability. By providing a standardized way to represent PCB layouts and manufacturing information, these files facilitate collaboration between designers, manufacturers, and assembly houses, streamlining the production process and reducing errors.

As the electronics industry continues to push the boundaries of what is possible, the role of PCB files will only become more critical. Designers and manufacturers who stay current with the latest file formats, design tools, and best practices will be well-positioned to meet the challenges of the future and deliver innovative, high-quality electronic products to market.

Leave a Reply