Introduction to LED PCB

An LED PCB, or Light Emitting Diode Printed Circuit Board, is a specialized type of printed circuit board designed to efficiently power and control LED lights. LED-PCBs are widely used in various applications, from consumer electronics and automotive lighting to industrial and architectural illumination. The combination of LEDs and PCBs offers numerous advantages, such as improved energy efficiency, longer lifespan, and enhanced design flexibility compared to traditional lighting solutions.

How LED PCBs Work

LED PCBs operate by supplying electrical current to the connected LED components, which then emit light through a process called electroluminescence. The PCB serves as a base for mounting the LEDs and provides the necessary electrical connections and circuitry to control and power the LEDs.

Key Components of an LED PCB

- Substrate: The foundation of the PCB, typically made of FR-4 or aluminum, which provides mechanical support and electrical insulation.

- Copper Traces: Conductive paths etched onto the substrate that carry electrical signals and power to the LED components.

- Solder Mask: A protective layer that covers the copper traces, preventing short circuits and oxidation while also providing insulation.

- Silkscreen: A printed layer that adds text, logos, and component identifiers to the PCB for easier assembly and identification.

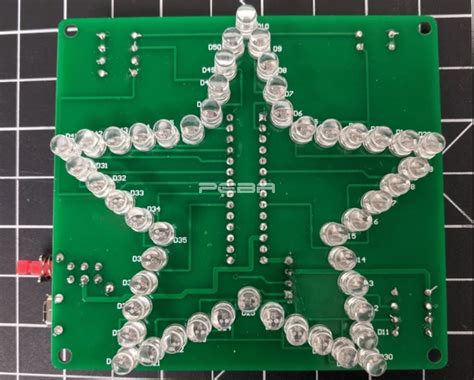

- LED Components: The light-emitting diodes mounted on the PCB, which can be surface-mounted (SMD) or through-hole (THT).

LED PCB Circuit Design Considerations

When designing an LED PCB, several factors must be taken into account to ensure optimal performance and reliability:

- Current and Voltage Requirements: LEDs require specific current and voltage levels to operate efficiently. The PCB design must incorporate appropriate resistors and power regulation circuitry to deliver the correct power to the LEDs.

- Thermal Management: LEDs generate heat during operation, which can affect their performance and lifespan. LED PCBs often feature thermal management solutions, such as metal-core PCBs (MCPCBs) or heatsinks, to dissipate heat effectively.

- LED Placement and Spacing: The arrangement of LEDs on the PCB impacts the overall light distribution and uniformity. Proper spacing and placement of LEDs are crucial for achieving the desired illumination pattern and avoiding hotspots or shadowing.

- Dimming and Control: Many LED PCBs incorporate dimming and control circuitry, allowing for adjustable brightness and color temperature. This can be achieved through pulse-width modulation (PWM) or analog dimming techniques.

Advantages of Using LED PCBs

LED PCBs offer several benefits over traditional lighting solutions:

- Energy Efficiency: LEDs consume significantly less power compared to incandescent or fluorescent lights, resulting in lower energy costs and reduced environmental impact.

- Long Lifespan: LED PCBs can last up to 50,000 hours or more, minimizing maintenance and replacement costs.

- Design Flexibility: The compact size and versatility of LED PCBs allow for innovative and space-saving lighting designs.

- Enhanced Durability: LED PCBs are resistant to shock, vibration, and extreme temperatures, making them suitable for harsh environments.

- Instant On/Off: Unlike traditional lights, LEDs reach full brightness instantly and can be switched on and off rapidly without affecting their lifespan.

Applications of LED PCBs

LED PCBs find applications in various industries and sectors, including:

- Automotive Lighting: LED PCBs are used in headlights, taillights, interior lighting, and instrument panel illumination.

- Consumer Electronics: LED PCBs are found in smartphones, tablets, laptops, televisions, and other electronic devices for backlighting and indicator lights.

- Architectural Lighting: LED PCBs are employed in indoor and outdoor architectural lighting, such as building facades, landscapes, and signage.

- Industrial Lighting: LED PCBs are used in warehouses, factories, and other industrial settings for energy-efficient and long-lasting illumination.

- Medical Devices: LED PCBs are incorporated into medical equipment, such as surgical lights, endoscopes, and dental instruments, for precise and reliable lighting.

LED PCB Manufacturing Process

The manufacturing process for LED PCBs involves several key steps:

- PCB Design: The LED PCB layout is designed using computer-aided design (CAD) software, taking into account the specific requirements of the application.

- PCB Fabrication: The designed PCB is manufactured using a series of processes, including substrate preparation, copper etching, solder mask application, and silkscreen printing.

- LED Mounting: The LED components are mounted onto the PCB using Surface-Mount Technology (SMT) or through-hole technology (THT).

- Soldering: The mounted LEDs are soldered onto the PCB using reflow or wave soldering techniques, ensuring secure electrical connections.

- Testing and Inspection: The assembled LED PCB undergoes rigorous testing and inspection to ensure proper functionality, light output, and quality control.

Choosing the Right LED PCB for Your Application

When selecting an LED PCB for your application, consider the following factors:

- Lighting Requirements: Determine the desired light output, color temperature, and beam angle for your specific application.

- Environmental Conditions: Consider the operating environment, including temperature range, humidity, and exposure to dust or moisture, to choose an LED PCB with appropriate protection and thermal management.

- Power Supply: Ensure that the LED PCB is compatible with the available power supply and can operate within the required voltage and current range.

- Size and Form Factor: Select an LED PCB that fits within the available space and can be easily integrated into your application.

- Cost and Availability: Consider the cost and availability of the LED PCB, as well as the lead time and minimum order quantity (MOQ) required by the manufacturer.

| Factor | Consideration |

|---|---|

| Lighting Requirements | Desired light output, color temperature, and beam angle |

| Environmental Conditions | Operating temperature range, humidity, and exposure to dust or moisture |

| Power Supply | Compatibility with available power supply, required voltage, and current range |

| Size and Form Factor | Fitting within available space and ease of integration |

| Cost and Availability | Cost, lead time, and minimum order quantity (MOQ) |

Maintenance and Troubleshooting of LED PCBs

To ensure optimal performance and longevity of your LED PCB, follow these maintenance and troubleshooting tips:

- Regular Cleaning: Periodically clean the LED PCB to remove dust, dirt, and debris that can accumulate over time and affect the light output.

- Proper Ventilation: Ensure adequate ventilation around the LED PCB to prevent overheating and maintain optimal operating temperatures.

- Voltage and Current Monitoring: Regularly check the voltage and current supplied to the LED PCB to ensure they are within the specified range and prevent potential damage.

- Visual Inspection: Inspect the LED PCB for any signs of physical damage, such as cracks, burns, or discoloration, which may indicate a fault or potential failure.

- Replacement of Faulty Components: If an individual LED or other component fails, replace it promptly to prevent further damage to the PCB and maintain consistent light output.

Future Trends in LED PCB Technology

As technology advances, LED PCBs continue to evolve and improve. Some notable trends in LED PCB technology include:

- Miniaturization: The development of smaller and more compact LED PCBs allows for even greater design flexibility and integration into various applications.

- Intelligent Control: The incorporation of smart sensors and control systems enables LED PCBs to adapt to changing environments and user preferences, such as automatic dimming based on ambient light levels.

- Wireless Connectivity: The integration of wireless communication protocols, such as Bluetooth or Wi-Fi, allows for remote control and monitoring of LED PCBs through mobile apps or smart home systems.

- Sustainable Materials: The use of eco-friendly and recyclable materials in LED PCB manufacturing helps reduce environmental impact and promote sustainability.

- Enhanced Color Rendering: Advancements in LED technology lead to improved color rendering index (CRI) and a wider range of color temperatures, enabling more natural and accurate lighting.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between an LED PCB and a regular PCB?

A: An LED PCB is specifically designed to power and control LED lights, while a regular PCB is a general-purpose circuit board used for various electronic applications. -

Q: Can LED PCBs be used for outdoor lighting applications?

A: Yes, LED PCBs can be designed with appropriate protection and thermal management to withstand outdoor environmental conditions, such as exposure to moisture, dust, and extreme temperatures. -

Q: How long do LED PCBs typically last?

A: LED PCBs can last up to 50,000 hours or more, depending on factors such as operating conditions, thermal management, and quality of components used. -

Q: Are LED PCBs more energy-efficient than traditional lighting solutions?

A: Yes, LED PCBs consume significantly less power compared to incandescent or fluorescent lights, resulting in lower energy costs and reduced environmental impact. -

Q: Can LED PCBs be dimmed or controlled for different lighting effects?

A: Yes, many LED PCBs incorporate dimming and control circuitry, allowing for adjustable brightness and color temperature through techniques such as pulse-width modulation (PWM) or analog dimming.

Conclusion

LED PCBs have revolutionized the lighting industry, offering numerous advantages over traditional lighting solutions. By combining the energy efficiency, long lifespan, and design flexibility of LEDs with the reliability and functionality of printed circuit boards, LED PCBs have become an essential component in a wide range of applications, from consumer electronics and automotive lighting to architectural and industrial illumination.

As technology continues to advance, the future of LED PCBs looks bright, with ongoing developments in miniaturization, intelligent control, wireless connectivity, sustainable materials, and enhanced color rendering. By understanding the key aspects of LED PCBs, including their components, design considerations, manufacturing process, and maintenance requirements, you can effectively leverage this technology to create innovative and efficient lighting solutions for your specific application.

Leave a Reply