Introduction to SLA Batteries and Charging Circuits

Sealed Lead Acid (SLA) batteries are a popular choice for various applications due to their reliability, low maintenance, and cost-effectiveness. These batteries are commonly used in uninterruptible power supplies (UPS), emergency lighting systems, security systems, and even in some automotive applications. To ensure optimal performance and longevity of SLA batteries, it is essential to use a proper charging circuit. In this article, we will explore the basics of SLA batteries, their charging requirements, and provide a detailed guide on designing and implementing an efficient SLA charging circuit.

What are Sealed Lead Acid Batteries?

Sealed Lead Acid (SLA) batteries, also known as Valve Regulated Lead Acid (VRLA) batteries, are a type of rechargeable battery that uses lead plates and sulfuric acid electrolyte. Unlike traditional flooded lead acid batteries, SLA batteries are designed to be maintenance-free and leak-proof. They have a sealed construction with a pressure relief valve that allows the release of excess gas during overcharging, hence the name “valve regulated.”

SLA batteries come in two main types:

-

Absorbed Glass Mat (AGM) batteries: In AGM batteries, the electrolyte is absorbed into a fiberglass mat separator between the lead plates. This design minimizes the risk of leakage and allows for better shock and vibration resistance.

-

Gel Cell batteries: Gel Cell batteries use a gelled electrolyte, which is a mixture of sulfuric acid and silica. The gelled electrolyte provides a more stable and safer operation, especially in high-temperature environments.

Advantages of SLA Batteries

SLA batteries offer several advantages over traditional flooded lead acid batteries:

-

Maintenance-free: SLA batteries do not require regular topping up of the electrolyte, making them suitable for applications where maintenance is difficult or impractical.

-

Leak-proof: The sealed construction of SLA batteries minimizes the risk of electrolyte leakage, ensuring safer operation and reducing the risk of damage to the surrounding equipment.

-

Low self-discharge: SLA batteries have a lower self-discharge rate compared to other rechargeable batteries, allowing them to retain their charge for longer periods when not in use.

-

Wide operating temperature range: SLA batteries can operate in a wide range of temperatures, typically from -20°C to 60°C, making them suitable for various environments.

-

Shock and vibration resistant: The solid construction and immobilized electrolyte in SLA batteries provide excellent resistance to shocks and vibrations, making them ideal for portable and mobile applications.

Understanding SLA Battery Charging Requirements

To ensure optimal performance and longevity of SLA batteries, it is crucial to follow the proper charging requirements. Overcharging or undercharging can lead to reduced battery life and even permanent damage.

Charging Stages

SLA batteries typically require a three-stage charging process:

-

Bulk Charge: In this stage, the battery is charged at a constant current until it reaches approximately 70-80% of its capacity. The charging current is usually set to 10-30% of the battery’s rated capacity (C/10 to C/3).

-

Absorption Charge: Once the battery reaches the bulk charge voltage (typically 14.4V-14.7V for a 12V battery), the charging voltage is held constant while the current gradually decreases. This stage allows the battery to reach its full capacity without overcharging.

-

Float Charge: After the absorption charge, the battery is maintained at a lower voltage (typically 13.6V-13.8V for a 12V battery) to compensate for self-discharge and keep the battery at its optimal charge level.

Charging Voltage and Current

The charging voltage and current are critical parameters in the SLA battery charging process. The recommended charging voltage for a 12V SLA battery is as follows:

- Bulk Charge: 14.4V-14.7V

- Absorption Charge: 14.4V-14.7V

- Float Charge: 13.6V-13.8V

The charging current should be set based on the battery’s rated capacity. A common rule of thumb is to use a charging current equal to 10-30% of the battery’s capacity (C/10 to C/3). For example, a 10Ah battery can be charged at 1A to 3A.

Temperature Compensation

Temperature plays a crucial role in the charging process of SLA batteries. As the temperature increases, the battery’s internal resistance decreases, leading to a higher charging current and potential overcharging. Conversely, at lower temperatures, the internal resistance increases, resulting in slower charging and potentially undercharging.

To account for temperature variations, it is recommended to incorporate temperature compensation in the charging circuit. The charging voltage should be adjusted based on the ambient temperature to ensure optimal charging. A typical temperature compensation factor is -3mV/°C to -5mV/°C per cell.

Designing an SLA Battery Charging Circuit

Now that we understand the charging requirements of SLA batteries, let’s dive into designing an efficient and reliable charging circuit.

Key Components

-

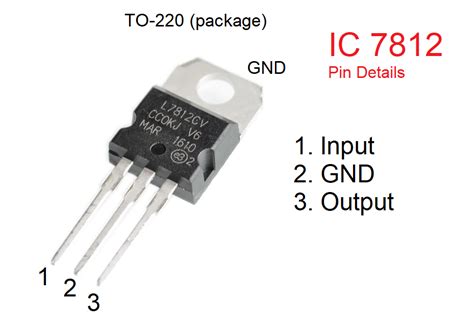

Voltage Regulator: A voltage regulator is used to maintain a constant charging voltage during the bulk and absorption charging stages. Common choices include linear regulators (e.g., LM317) or switching regulators (e.g., buck converters).

-

Current Limiter: A current limiter is necessary to prevent excessive charging current that can damage the battery. This can be achieved using a resistor in series with the battery or by controlling the current through the voltage regulator.

-

Temperature Sensor: To implement temperature compensation, a temperature sensor (e.g., thermistor or IC temperature sensor) is used to measure the ambient temperature near the battery.

-

Microcontroller or Analog Control Circuit: A microcontroller or analog control circuit is used to monitor the battery voltage, control the charging stages, and adjust the charging voltage based on temperature feedback.

-

Protection Circuitry: Additional protection circuitry, such as reverse polarity protection and overcharge protection, can be included to safeguard the battery and the charging circuit.

Circuit Diagram

Here’s a simplified schematic diagram of an SLA battery charging circuit:

+---------+

| |

| Power |

| Supply |

| |

+----+----+

|

|

+----+----+

| |

| Voltage |

|Regulator|

| |

+----+----+

|

|

+----+----+

| |

| Current |

| Limiter |

| |

+----+----+

|

|

+----+----+

| |

| SLA |

| Battery |

| |

+----+----+

|

|

+----+----+

| |

| Temp |

| Sensor |

| |

+----+----+

|

|

+----+----+

| |

| Micro- |

|controller|

| |

+----+----+

In this circuit, the power supply provides the necessary input voltage to the voltage regulator. The voltage regulator maintains a constant charging voltage, which is then fed to the current limiter. The current limiter ensures that the charging current does not exceed the recommended value for the battery.

The SLA battery is connected to the output of the current limiter. The temperature sensor is placed near the battery to measure the ambient temperature. The microcontroller reads the temperature sensor and adjusts the charging voltage accordingly using temperature compensation.

Charging Algorithm

The microcontroller implements the three-stage charging algorithm based on the battery voltage and charging time. Here’s a simplified flowchart of the charging algorithm:

+------------------+

| Start Charging |

+------------------+

|

v

+------------------+

| Bulk Charging |

| (CC Mode) |

+------------------+

|

v

+------------------+

|Battery Voltage |

| >= 14.4V? |

+------------------+

|

Yes | No

v

+------------------+

| Absorption |

| Charging |

| (CV Mode) |

+------------------+

|

v

+------------------+

| Charging |

| Current <= C/10?|

+------------------+

|

Yes | No

v

+------------------+

| Float Charging |

| (CV Mode) |

+------------------+

|

v

+------------------+

| End Charging |

+------------------+

During the bulk charging stage, the battery is charged at a constant current (CC) until the battery voltage reaches the bulk charge voltage (e.g., 14.4V). Then, the charging enters the absorption stage, where the voltage is held constant (CV) while the current gradually decreases. Once the charging current drops below a certain threshold (usually C/10), the charging transitions to the float stage, where a lower constant voltage is maintained to keep the battery at its optimal charge level.

Temperature Compensation

To implement temperature compensation, the microcontroller reads the temperature sensor and adjusts the charging voltage based on the following formula:

V_charge = V_ref - (T_ambient - T_ref) * Temperature_Compensation_Factor

Where:

– V_charge is the adjusted charging voltage

– V_ref is the reference charging voltage at the reference temperature (e.g., 25°C)

– T_ambient is the measured ambient temperature

– T_ref is the reference temperature (e.g., 25°C)

– Temperature_Compensation_Factor is the compensation factor in mV/°C per cell (e.g., -3mV/°C to -5mV/°C)

By adjusting the charging voltage based on the ambient temperature, the charging circuit ensures optimal charging performance and extends the battery life.

Implementing the SLA Battery Charging Circuit

Now that we have designed the SLA battery charging circuit, let’s discuss the implementation details.

Component Selection

-

Voltage Regulator: Choose a voltage regulator that can handle the required charging voltage and current. For a 12V SLA battery, a regulator with an output voltage range of 13.6V to 14.7V and a current rating higher than the maximum charging current is suitable. Examples include LM317 for linear regulation or a buck converter module for switching regulation.

-

Current Limiter: The current limiter can be implemented using a resistor in series with the battery or by controlling the current through the voltage regulator. For a resistor-based current limiter, choose a resistor value that limits the current to the desired level (e.g., R = (V_regulator – V_battery) / I_max). For a regulator-based current limiter, use the regulator’s current limiting feature or an external current sense resistor.

-

Temperature Sensor: Select a temperature sensor that is compatible with the microcontroller and provides accurate readings. Options include thermistors (e.g., NTC or PTC) or IC temperature sensors (e.g., LM35, DS18B20).

-

Microcontroller: Choose a microcontroller that has sufficient I/O pins, ADC channels, and processing power to handle the charging algorithm and temperature compensation. Popular choices include Arduino, PIC, or AVR microcontrollers.

-

Protection Components: Include appropriate protection components such as reverse polarity protection diodes, fuses, and overcharge protection circuits to ensure the safety and reliability of the charging circuit.

Software Implementation

The charging algorithm and temperature compensation can be implemented using the microcontroller’s programming language (e.g., C/C++ for Arduino). Here’s a simplified code snippet illustrating the main steps:

void setup() {

// Initialize ADC, I/O pins, and temperature sensor

}

void loop() {

// Read battery voltage and temperature

float batteryVoltage = readBatteryVoltage();

float temperature = readTemperature();

// Determine charging stage based on battery voltage

if (batteryVoltage < 14.4) {

// Bulk Charging (CC Mode)

setChargingVoltage(14.4);

setChargingCurrent(maxChargingCurrent);

} else if (batteryVoltage >= 14.4 && chargingCurrent > batteryCapacity / 10) {

// Absorption Charging (CV Mode)

setChargingVoltage(14.4);

} else {

// Float Charging (CV Mode)

setChargingVoltage(13.6);

}

// Apply temperature compensation

float compensatedVoltage = 14.4 - (temperature - 25) * 0.003;

setChargingVoltage(compensatedVoltage);

// Delay before next iteration

delay(1000);

}

In the setup() function, initialize the necessary peripherals such as ADC, I/O pins, and the temperature sensor.

In the loop() function, read the battery voltage and temperature using the ADC and temperature sensor. Determine the charging stage based on the battery voltage and charging current. Set the appropriate charging voltage and current accordingly.

Apply temperature compensation by adjusting the charging voltage based on the measured temperature and the compensation factor.

Repeat the process periodically to continuously monitor and control the charging process.

Testing and Calibration

Before deploying the SLA battery charging circuit, it is essential to test and calibrate it to ensure accurate and safe operation. Follow these steps:

-

Verify the functionality of the voltage regulator, current limiter, and protection circuits using a power supply and a dummy load (e.g., a resistor).

-

Calibrate the ADC readings for accurate voltage and temperature measurements. Use a multimeter to measure the actual battery voltage and compare it with the ADC readings. Adjust the ADC calibration factors if necessary.

-

Test the charging algorithm by connecting an SLA battery to the charging circuit. Monitor the battery voltage, charging current, and temperature over time to ensure proper charging stages and temperature compensation.

-

Validate the overcharge protection and safety features by intentionally inducing fault conditions (e.g., short circuit, reverse polarity) and verifying that the protection mechanisms activate as expected.

-

Perform long-term testing to assess the reliability and performance of the charging circuit under various operating conditions and battery states.

Frequently Asked Questions (FAQ)

-

Can I use this SLA battery charging circuit for different battery voltages?

Yes, the charging circuit can be adapted for different battery voltages by adjusting the voltage regulator output and modifying the charging voltage set points in the software. However, ensure that the voltage regulator and other components are rated for the desired voltage range. -

What should I do if the battery is not charging properly?

If the battery is not charging properly, first check the connections and ensure that there are no loose or corroded terminals. Verify that the power supply is providing the correct input voltage to the charging circuit. If the issue persists, troubleshoot the individual components (voltage regulator, current limiter, temperature sensor) and check the software for any logical errors or incorrect calibration values. -

How long does it take to fully charge an SLA battery?

The charging time depends on the battery capacity and the charging current. As a general rule, it takes approximately 10 to 15 hours to fully charge an SLA battery using a charging current of C/10 (10% of the battery capacity). For example, a 10Ah battery charged at 1A will take around 10 to 15 hours to reach full charge. -

Can I leave the SLA battery connected to the charging circuit indefinitely?

Yes, once the battery reaches the float charging stage, it can be left connected to the charging circuit indefinitely. The float charge voltage maintains the battery at its optimal charge level and compensates for self-discharge. However, it is recommended to periodically check the battery health and performance to ensure long-term reliability. -

What safety precautions should I take when working with SLA batteries and charging circuits?

When working with SLA batteries and charging circuits, follow these safety precautions: - Wear protective gloves and eyewear to avoid contact with the battery electrolyte.

- Work in a well-ventilated area to prevent the accumulation of hydrogen gas, which can be explosive.

- Avoid short-circuiting the battery terminals or the charging circuit, as it can cause high currents and generate heat.

- Disconnect the power supply and battery when making any modifications or repairs to the charging circuit.

- Follow the manufacturer’s guidelines for handling, storage, and disposal of SLA batteries.

Conclusion

Designing and implementing an efficient and reliable SLA battery charging circuit is crucial for optimizing battery performance and longevity. By understanding the charging requirements, selecting appropriate components, and implementing a robust charging algorithm with temperature compensation, you can ensure that your SLA batteries are charged safely and effectively.

Remember to always prioritize safety and follow best practices when working with batteries and electrical circuits. Regular testing, calibration, and maintenance will help you identify and address any issues promptly, ensuring the long-term reliability of your SLA battery charging system

Leave a Reply