Rogers RT/duroid 5880LZ is a high-frequency laminated material that has become a popular choice for microwave applications. Its high dielectric constant and low loss tangent make it ideal for use in high-frequency circuits, such as antennas, amplifiers, and filters. This article will provide an overview of Rogers RT/duroid 5880LZ, its properties, and its applications in the field of microwave engineering.

The RT/duroid 5880LZ is a PTFE composite material that is reinforced with woven glass microfibers. It has a dielectric constant of 2.2, which is relatively high for a laminate material, and a loss tangent of 0.0009, which is exceptionally low. These properties make it an excellent choice for circuits that require low loss and high frequency stability. The material is also highly resistant to moisture, which makes it suitable for use in harsh environments.

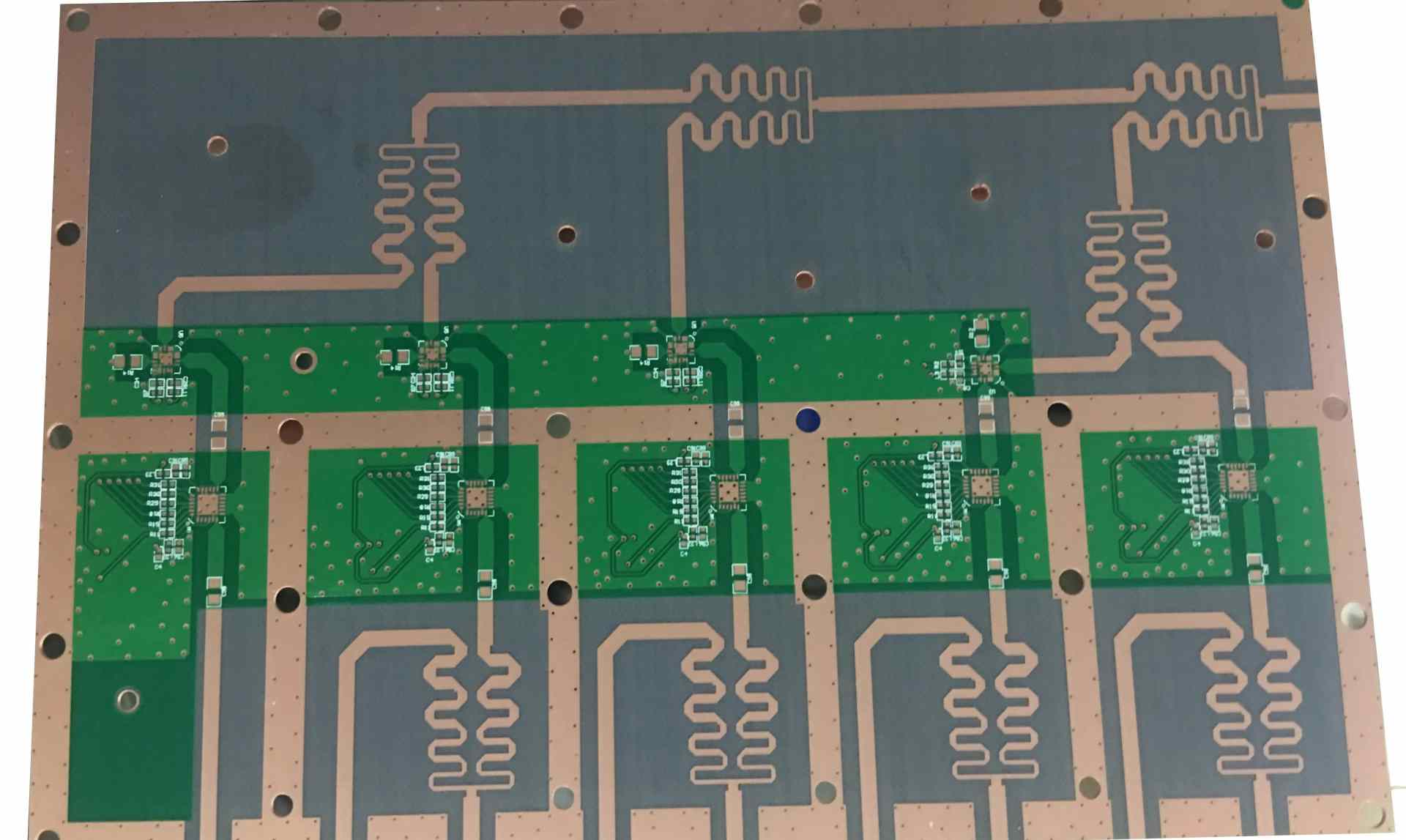

The RT/duroid 5880LZ has found applications in a wide range of microwave circuits, including power amplifiers, filters, and antennas. Its low loss tangent allows for high Q-factor resonators, which are essential for filter designs. The material is also used in high-power applications, where its thermal stability and low loss are critical. In conclusion, Rogers RT/duroid 5880LZ is a versatile material that has become a popular choice for microwave engineers due to its excellent properties and wide range of applications.

Overview of Rogers RT/duroid 5880LZ

Rogers RT/duroid 5880LZ is a high-frequency laminate material that is widely used in the design and construction of microwave circuits and systems. It is a PTFE-based composite material that provides excellent electrical performance, low loss, and high reliability.

The RT/duroid 5880LZ material has a dielectric constant (Dk) of 2.2, which is stable over a wide range of frequencies and temperatures. This makes it an ideal choice for high-frequency applications where signal integrity and stability are critical.

In addition to its excellent electrical properties, RT/duroid 5880LZ also has a low coefficient of thermal expansion (CTE), which ensures dimensional stability and reliability in harsh environments. It is also resistant to moisture, chemicals, and other environmental factors that can affect the performance of microwave circuits.

The RT/duroid 5880LZ material is available in various thicknesses, ranging from 0.003″ to 0.250″. It can be supplied with either smooth or textured copper foil, depending on the specific application requirements.

Overall, Rogers RT/duroid 5880LZ is a reliable and high-performance material that is widely used in the design and construction of microwave circuits and systems. Its excellent electrical properties, low loss, and high reliability make it an ideal choice for high-frequency applications where signal integrity and stability are critical.

Physical Properties

Material Composition

Rogers RT/duroid 5880LZ is a high-frequency laminate material that is made up of woven glass fabric and a PTFE (Polytetrafluoroethylene) composite. This material is known for its excellent electrical performance, low dielectric loss, and high thermal stability.

The glass fabric used in the laminate is impregnated with a proprietary PTFE resin system, which makes the material highly resistant to chemical attack, moisture, and other environmental factors. The dielectric constant of RT/duroid 5880LZ is 2.2, which is very low compared to other high-frequency laminates.

Dimensional Stability

One of the key features of Rogers RT/duroid 5880LZ is its excellent dimensional stability. The material has a low coefficient of thermal expansion (CTE), which means that it is less likely to warp or deform when exposed to changes in temperature. This makes it an ideal choice for applications where temperature stability is critical, such as in aerospace, defense, and telecommunications.

The table below summarizes the key physical properties of Rogers RT/duroid 5880LZ:

| Property | Value |

|---|---|

| Dielectric constant | 2.2 |

| Dissipation factor | 0.0009 |

| Thermal conductivity | 0.66 W/m-K |

| Coefficient of thermal expansion (CTE) | 17 ppm/°C |

| Tensile strength | 120 MPa |

| Water absorption | < 0.04% |

In summary, Rogers RT/duroid 5880LZ is a high-performance laminate material that is ideal for high-frequency applications that require excellent electrical performance and dimensional stability. Its low dielectric constant, low dissipation factor, and high thermal stability make it a popular choice for a wide range of industries, including aerospace, defense, and telecommunications.

Electrical Properties

Dielectric Constant

Rogers RT/duroid 5880LZ has a low dielectric constant of 2.2, making it an excellent choice for high-frequency applications. The low dielectric constant reduces signal loss, resulting in better signal integrity. This material is commonly used in microwave and millimeter-wave circuits, where high-frequency performance is critical.

Loss Tangent

The loss tangent of Rogers RT/duroid 5880LZ is very low, typically around 0.0009 at 10 GHz. This means that the material has very low loss, which is essential for high-frequency applications. The low loss tangent ensures that the signal is not absorbed by the substrate, resulting in better signal quality.

In summary, Rogers RT/duroid 5880LZ has excellent electrical properties, including a low dielectric constant and a low loss tangent. These properties make it an ideal choice for high-frequency applications, such as microwave and millimeter-wave circuits.

Thermal Properties

Thermal Conductivity

Rogers RT/duroid 5880LZ has a thermal conductivity of 0.66 W/mK. This value is relatively low compared to other materials used in high-frequency applications, such as copper (401 W/mK) or aluminum (237 W/mK). However, it is important to note that the thermal conductivity of a material is not the only factor that determines its ability to dissipate heat. Other properties, such as thermal resistance and thermal capacity, also play a role.

Thermal Expansion Coefficient

The thermal expansion coefficient of Rogers RT/duroid 5880LZ is 17 ppm/°C. This value indicates how much the material will expand or contract when subjected to temperature changes. A high thermal expansion coefficient can cause issues in high-frequency applications, as it can lead to changes in the dimensions of the material and affect its performance. However, the thermal expansion coefficient of RT/duroid 5880LZ is relatively low, which makes it a suitable choice for applications where dimensional stability is crucial.

In summary, Rogers RT/duroid 5880LZ has a relatively low thermal conductivity but a low thermal expansion coefficient, which makes it a suitable choice for high-frequency applications where dimensional stability is crucial.

Applications of Rogers RT/duroid 5880LZ

Rogers RT/duroid 5880LZ is a high-performance circuit material that has gained popularity in recent years due to its exceptional electrical properties and mechanical stability. This material has a low dielectric constant and loss tangent, making it ideal for high-frequency applications. Here are some of the applications where Rogers RT/duroid 5880LZ is commonly used:

Telecommunications

Rogers RT/duroid 5880LZ is widely used in the telecommunications industry for applications such as antennas, filters, and power amplifiers. The low loss tangent of this material ensures that the signal loss is minimal, resulting in better signal transmission and reception.

Aerospace and Defense

Rogers RT/duroid 5880LZ is also used in the aerospace and defense industry for applications such as radar systems, satellite communication systems, and electronic warfare systems. This material is known for its high thermal stability and low moisture absorption, making it suitable for use in harsh environments.

Automotive

Rogers RT/duroid 5880LZ is used in the automotive industry for applications such as collision avoidance systems, radar systems, and infotainment systems. The low dielectric constant of this material ensures that the signal loss is minimal, resulting in better performance and reliability.

Medical

Rogers RT/duroid 5880LZ is also used in the medical industry for applications such as MRI machines and other medical imaging equipment. The low loss tangent of this material ensures that the signal loss is minimal, resulting in better image quality and accuracy.

In conclusion, Rogers RT/duroid 5880LZ is a versatile circuit material that finds applications in a wide range of industries. Its exceptional electrical properties and mechanical stability make it an ideal choice for high-frequency applications where signal loss is a critical factor.

Handling and Processing

Rogers RT/duroid 5880LZ is a high-performance laminate material that requires careful handling and processing to achieve optimal results. Here are some key considerations to keep in mind:

-

Storage: The material should be stored in a clean, dry, and temperature-controlled environment to prevent moisture absorption and warping. It is recommended to store the material in its original packaging until it is ready for use.

-

Cutting: The material can be cut using a variety of methods, including mechanical saws, routers, and lasers. It is important to use appropriate cutting tools and techniques to prevent delamination and chipping. The material should be securely clamped or vacuumed to prevent movement during cutting.

-

Drilling: The material can be drilled using standard carbide drills or diamond-coated drills. It is important to use appropriate drilling speeds and feeds to prevent overheating and delamination. Pre-drilling a pilot hole can also help prevent chipping.

-

Cleaning: The material should be cleaned using a mild detergent and water solution or isopropyl alcohol. Abrasive cleaners or solvents should be avoided as they can damage the surface finish.

-

Etching: The material can be etched using a variety of methods, including chemical etching and plasma etching. It is important to follow appropriate safety precautions and to use etchants that are compatible with the material.

Overall, Rogers RT/duroid 5880LZ is a versatile and reliable material that can be processed using a variety of techniques. With proper handling and processing, it can deliver exceptional performance in a wide range of applications.

Safety Measures

When working with Rogers RT/duroid 5880LZ, it is important to follow proper safety measures to avoid any potential hazards. Here are some guidelines to keep in mind:

-

Wear protective gear: Always wear appropriate protective gear, including gloves, goggles, and a respirator, when handling RT/duroid 5880LZ. This will help protect you from any potential exposure to hazardous materials.

-

Store the material properly: Store RT/duroid 5880LZ in a dry, cool place away from direct sunlight. This will help prevent any degradation of the material and maintain its quality.

-

Use appropriate tools: Use tools that are specifically designed for working with RT/duroid 5880LZ. This will help ensure that the material is handled properly and reduce the risk of damage.

-

Avoid inhalation: Avoid inhaling any dust or particles that may be released when working with RT/duroid 5880LZ. This can be achieved by working in a well-ventilated area or using a respirator.

-

Follow proper disposal procedures: Dispose of any unused or waste material according to local regulations. This will help protect the environment and prevent any potential hazards.

By following these safety measures, you can ensure that you are working with Rogers RT/duroid 5880LZ in a safe and responsible manner.

Conclusion

In conclusion, Rogers RT/duroid 5880LZ is a high-performance laminate material that is ideal for use in high-frequency applications. The material offers a low dielectric constant and loss tangent, making it suitable for applications that require low insertion loss and high signal integrity.

With its high thermal stability and mechanical strength, RT/duroid 5880LZ can withstand harsh environmental conditions, making it a reliable choice for applications in aerospace, defense, and telecommunications industries.

The material’s excellent dimensional stability and consistent electrical properties make it easy to work with and ensure that the final product meets the required specifications. Additionally, the material’s compatibility with standard fabrication processes makes it easy to integrate into existing designs.

Overall, Rogers RT/duroid 5880LZ is a high-quality material that offers excellent electrical and mechanical properties, making it a reliable choice for a range of high-frequency applications.

Leave a Reply