Rogers RO4400 is a high-performance circuit material that is widely used in the electronics industry. It is a high-frequency laminate that offers excellent signal integrity, low loss, and high reliability. The material is designed to meet the demanding requirements of high-speed digital and RF applications, making it an ideal choice for a wide range of applications.

One of the key features of Rogers RO4400 is its low dielectric loss, which makes it an excellent choice for high-frequency applications. The material has a low dissipation factor, which means that it can transmit signals with minimal loss. This makes it an ideal choice for applications such as telecommunications, satellite communications, and radar systems.

Another important feature of Rogers RO4400 is its high thermal conductivity. This allows the material to dissipate heat quickly, which is essential for high-power applications. The material is also highly resistant to moisture and chemicals, which makes it ideal for use in harsh environments. Overall, Rogers RO4400 is a high-performance material that offers excellent electrical and mechanical properties, making it an ideal choice for a wide range of applications.

Overview of Rogers RO4400

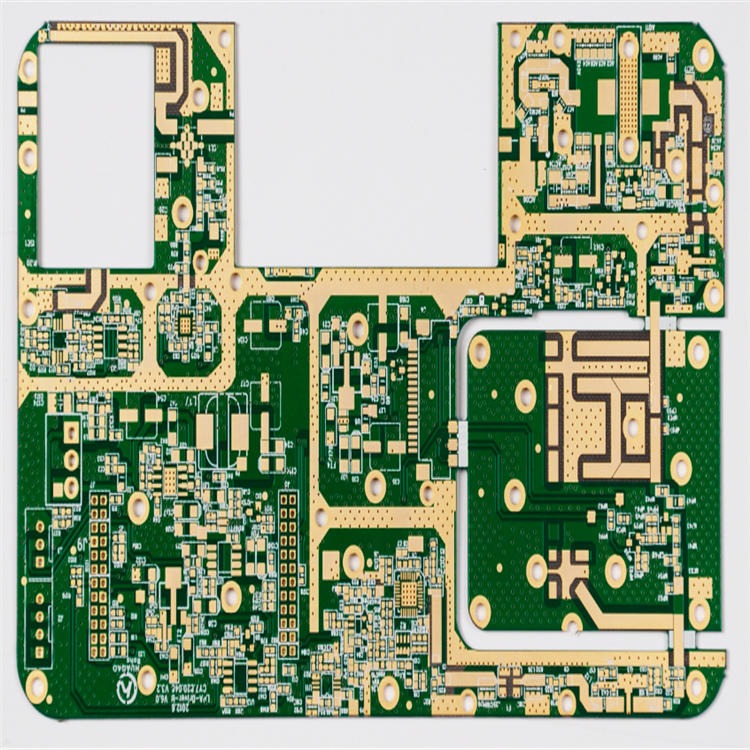

Rogers RO4400 is a high-frequency circuit material that is widely used in the design of high-performance printed circuit boards (PCBs). This material is made up of a woven fiberglass substrate that is impregnated with a proprietary blend of polytetrafluoroethylene (PTFE) and ceramic fillers. The result is a material that offers excellent electrical performance, low loss, and high reliability.

One of the key benefits of Rogers RO4400 is its low dielectric constant (Dk) and loss tangent (Df). These properties make it an ideal choice for high-frequency applications where signal integrity is critical. With a Dk of 3.38 and a Df of 0.0027 at 10 GHz, this material offers superior electrical performance compared to other PCB materials.

In addition to its electrical properties, Rogers RO4400 is also known for its excellent thermal stability and mechanical strength. This material can withstand temperatures up to 260°C without significant degradation, making it suitable for use in harsh environments. Its high mechanical strength also makes it resistant to cracking and deformation, ensuring the reliability of the PCB over its lifetime.

Overall, Rogers RO4400 is a high-performance PCB material that offers excellent electrical performance, thermal stability, and mechanical strength. Its low Dk and Df make it an ideal choice for high-frequency applications, while its reliability and durability make it suitable for use in harsh environments.

Key Features of Rogers RO4400

Electrical Properties

Rogers RO4400 is a high-frequency laminate material that offers excellent electrical properties. Its dielectric constant (Dk) ranges from 3.38 to 3.66, making it suitable for applications that require low signal loss. The material also has a tight tolerance of ±0.05 on Dk, ensuring consistent performance across different batches.

The dissipation factor (Df) of Rogers RO4400 is also low, ranging from 0.0025 to 0.0037, which translates to low signal attenuation. This makes it an ideal choice for high-frequency applications such as RF and microwave circuits.

Rogers RO4400 is also a low-loss material, with a loss tangent that ranges from 0.0015 to 0.0022 at 10 GHz. This low-loss characteristic makes it suitable for applications that require high signal integrity and low noise.

Thermal Properties

In addition to its excellent electrical properties, Rogers RO4400 also offers good thermal stability. The material has a Tg (glass transition temperature) of 280°C, which means it can withstand high-temperature environments without losing its mechanical or electrical properties.

Rogers RO4400 also has a low coefficient of thermal expansion (CTE), ranging from 13 to 17 ppm/°C. This means that it is less prone to thermal stress and can maintain its shape and structural integrity even under extreme temperature changes.

Overall, Rogers RO4400 is a high-performance material that offers excellent electrical and thermal properties. Its low-loss characteristic, tight Dk tolerance, and good thermal stability make it an ideal choice for high-frequency applications that require consistent performance and reliability.

Applications of Rogers RO4400

Rogers RO4400 is a high-performance circuit material that is widely used in various applications. This section will discuss two major applications of Rogers RO4400: Aerospace and Telecommunications.

Aerospace

Rogers RO4400 is an ideal choice for aerospace applications due to its excellent electrical properties and high reliability. It is commonly used in radar systems, satellite communication systems, and other aerospace electronics.

One of the key advantages of Rogers RO4400 is its low dielectric constant (Dk) and low loss tangent (Df) values, which enable it to provide superior signal integrity and reduced signal distortion. This is particularly important in high-frequency applications where signal quality is critical.

Another advantage of Rogers RO4400 is its high thermal conductivity, which makes it an excellent choice for applications that require efficient heat dissipation. This is especially important in aerospace applications where electronics are exposed to extreme temperatures and thermal management is crucial.

Telecommunications

Rogers RO4400 is also widely used in telecommunications applications due to its excellent electrical properties and high reliability. It is commonly used in high-speed digital circuits, wireless communication systems, and other telecommunications electronics.

One of the key advantages of Rogers RO4400 in telecommunications applications is its high-frequency performance. It provides low insertion loss and excellent signal integrity, making it an ideal choice for high-speed digital circuits and wireless communication systems.

Another advantage of Rogers RO4400 is its low outgassing properties, which make it suitable for use in vacuum environments. This is particularly important in space-based telecommunications applications where electronics are exposed to vacuum conditions.

In summary, Rogers RO4400 is a versatile and reliable circuit material that is widely used in aerospace and telecommunications applications. Its excellent electrical properties, high reliability, and thermal management capabilities make it an ideal choice for high-performance electronics.

Manufacturing Process

The Rogers RO4400 is a high-performance circuit material that is widely used in the electronics industry. The manufacturing process of Rogers RO4400 involves several steps that are carefully designed to ensure the highest quality and performance of the material.

The process begins with the selection of high-quality raw materials, which are then carefully inspected to ensure that they meet the required specifications. The raw materials are then mixed together in a precise ratio to form a homogeneous mixture.

The mixture is then subjected to a series of pressing and curing steps that result in the formation of a solid sheet of material. The sheet is then subjected to a series of machining and finishing steps to achieve the desired thickness, surface finish, and other properties.

During the manufacturing process, the material is subjected to strict quality control measures to ensure that it meets the required specifications. This includes testing the material for its electrical, mechanical, and thermal properties, as well as its chemical composition and purity.

Overall, the manufacturing process of Rogers RO4400 is a complex and highly controlled process that is designed to ensure the highest quality and performance of the material. With its excellent electrical and mechanical properties, Rogers RO4400 is an ideal choice for a wide range of electronic applications.

Advantages and Limitations

Rogers RO4400 is a high-performance circuit material that offers numerous advantages over other materials. However, it also has some limitations that need to be considered before choosing it for a particular application.

Advantages

-

Low Dielectric Loss: Rogers RO4400 has a low dielectric loss, which makes it an ideal choice for high-frequency applications. It offers low insertion loss, excellent signal integrity, and reduced crosstalk.

-

High Thermal Conductivity: The material has high thermal conductivity, which helps in dissipating heat from the circuit. It can handle high power levels and offers stable performance over a wide range of temperatures.

-

Stable Electrical Properties: Rogers RO4400 has stable electrical properties, which means it offers consistent performance over time. It has a low coefficient of thermal expansion, which reduces the risk of delamination and cracking.

-

Ease of Processing: The material is easy to process and can be used in a variety of applications. It can be drilled, routed, and machined using standard tools and techniques.

Limitations

-

Cost: Rogers RO4400 is relatively expensive compared to other materials. It may not be suitable for applications with tight budget constraints.

-

Limited Availability: The material may not be readily available in all regions. It may require longer lead times or higher minimum order quantities.

-

Processing Constraints: Rogers RO4400 has some processing constraints that need to be considered. It requires controlled environments and specialized equipment for processing.

In conclusion, Rogers RO4400 is a high-performance circuit material that offers several advantages over other materials. However, it also has some limitations that need to be considered before choosing it for a particular application.

Comparisons with Other Materials

When compared to other materials, Rogers RO4400 stands out in terms of its performance and versatility. Here are some of the key comparisons between Rogers RO4400 and other materials:

Rogers RO4000 vs FR-4

FR-4 is a common material used in PCBs due to its low cost. However, when it comes to performance, Rogers RO4400 outperforms FR-4 in several ways. For example, Rogers RO4400 has a higher dielectric constant, lower loss tangent, and better thermal stability compared to FR-4. This makes it a better choice for high-frequency applications where signal integrity is critical.

Rogers RO4000 vs PTFE

PTFE is another popular material used in high-frequency applications. While PTFE has excellent electrical properties, it is not as mechanically robust as Rogers RO4400. Rogers RO4400 has a higher glass transition temperature and better dimensional stability, making it a better choice for applications where mechanical strength is important.

Rogers RO4000 vs Ceramic

Ceramic materials are often used in high-power applications due to their excellent thermal conductivity. However, ceramics are brittle and can be difficult to work with. Rogers RO4400 offers a good balance between thermal conductivity and mechanical strength, making it a better choice for applications where both properties are important.

In summary, Rogers RO4400 is a versatile material that offers excellent performance in a wide range of applications. While there are other materials available, Rogers RO4400 stands out due to its superior electrical and mechanical properties.

Future Prospects

Rogers RO4400 has a bright future ahead of it. The demand for high-frequency laminates is expected to increase in the coming years, and Rogers RO4400 is well-positioned to meet this demand. The laminate’s excellent electrical and mechanical properties make it ideal for use in a wide range of applications, including aerospace, defense, telecommunications, and automotive.

In addition, Rogers Corporation is committed to ongoing research and development, which means that the company is always looking for ways to improve its products. This commitment to innovation ensures that Rogers RO4400 will continue to be a top-performing laminate well into the future.

Another factor that bodes well for the future of Rogers RO4400 is the company’s focus on sustainability. The laminate is manufactured using environmentally friendly processes, which makes it an attractive option for businesses looking to reduce their carbon footprint. As sustainability becomes an increasingly important consideration for companies across industries, Rogers RO4400 is well-positioned to capitalize on this trend.

Overall, the future looks bright for Rogers RO4400. With its exceptional electrical and mechanical properties, ongoing commitment to innovation, and focus on sustainability, this high-frequency laminate is poised to remain a top choice for a wide range of applications.

Leave a Reply