Rogers RO3006 is a high-frequency, low-loss laminate material that is widely used in the electronics industry. It is a ceramic-filled PTFE composite with excellent electrical properties, making it ideal for applications that require high performance and reliability. The material has a low dielectric constant and loss tangent, which makes it suitable for use in high-speed digital and RF circuits.

The RO3006 material has a low coefficient of thermal expansion, which makes it suitable for use in applications that require dimensional stability over a wide temperature range. It is also resistant to moisture and chemicals, which makes it ideal for use in harsh environments. The material is available in a variety of thicknesses and copper foil options, making it suitable for a wide range of applications in the telecommunications, aerospace, and defense industries.

Overall, the Rogers RO3006 material is a high-performance laminate material that offers excellent electrical properties, dimensional stability, and resistance to harsh environments. Its versatility and reliability make it a popular choice for a wide range of applications in the electronics industry.

Rogers RO3006 Overview

Rogers RO3006 is a high-frequency circuit material that is designed to deliver excellent electrical performance in a wide range of applications. It is a thermoset material that is reinforced with woven glass and has a dielectric constant of 6.15 ± 0.15.

The material features a low-loss tangent of 0.0025 at 10 GHz, making it ideal for applications that require low signal loss. It also has a low thermal coefficient of dielectric constant, which ensures that its electrical performance remains stable over a wide temperature range.

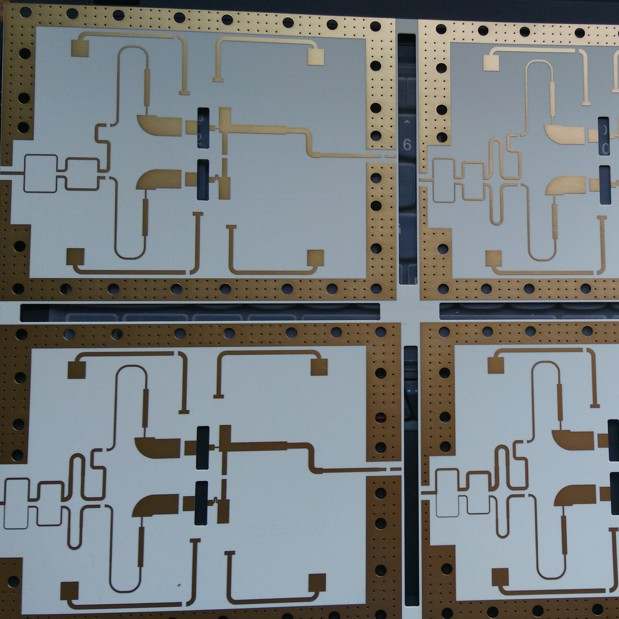

Rogers RO3006 is suitable for use in a variety of applications, including power amplifiers, filters, and antennas. It is also commonly used in the aerospace and defense industries, where high-frequency circuit materials are essential for reliable communication and data transmission.

The material is available in a range of thicknesses, from 0.003 to 0.020 inches, and can be supplied with a variety of copper foil options to meet specific application requirements. It is also compatible with a wide range of processing techniques, including laser drilling and mechanical drilling.

Overall, Rogers RO3006 is a high-performance circuit material that offers excellent electrical properties, thermal stability, and processing capabilities. It is an ideal choice for applications that require reliable high-frequency performance.

Key Features of Rogers RO3006

High Frequency Performance

Rogers RO3006 is a high-performance circuit material that offers excellent electrical properties at high frequencies. It has a low dielectric constant of 6.15 at 10 GHz and low loss tangent of 0.0023 at 10 GHz, which makes it ideal for use in high-frequency applications. RO3006 also has excellent electrical stability over a wide range of temperatures and frequencies.

Thermal Conductivity

RO3006 has a high thermal conductivity of 0.80 W/mK, which helps to dissipate heat generated by high-power components. This makes it ideal for use in applications where heat management is critical, such as power amplifiers and RF modules.

Dimensional Stability

RO3006 has excellent dimensional stability, which means that it maintains its shape and size even under extreme temperature and humidity conditions. This makes it ideal for use in applications where tight tolerances are required, such as microwave filters and couplers.

In summary, Rogers RO3006 is a high-performance circuit material that offers excellent electrical properties at high frequencies, high thermal conductivity, and excellent dimensional stability. These features make it ideal for use in a wide range of high-frequency applications where performance and reliability are critical.

Applications of Rogers RO3006

Rogers RO3006 is a high-frequency circuit material that has found various applications in the fields of communication systems, automotive radar, and aerospace technology. The material has excellent electrical and mechanical properties, making it ideal for use in high-performance applications.

Communication Systems

Rogers RO3006 is widely used in communication systems due to its low dielectric constant and loss. The material provides high signal integrity and low insertion loss, making it ideal for high-frequency applications such as microwave and millimeter-wave circuits. The material is also suitable for use in high-speed digital applications due to its low skew and dispersion.

Automotive Radar

Rogers RO3006 is also used in automotive radar systems due to its high thermal stability and low loss tangent. The material provides excellent signal integrity and low insertion loss, making it ideal for use in radar systems that require high accuracy and reliability. The material is also resistant to moisture and environmental factors, making it suitable for use in harsh automotive environments.

Aerospace Technology

Rogers RO3006 is also used in aerospace technology due to its high reliability and performance. The material is suitable for use in high-temperature applications and provides excellent signal integrity in harsh environments. The material is also lightweight and has excellent mechanical properties, making it ideal for use in aerospace applications such as satellite communications, avionics, and radar systems.

In conclusion, Rogers RO3006 is a versatile material that has found various applications in the fields of communication systems, automotive radar, and aerospace technology. The material provides excellent electrical and mechanical properties, making it ideal for use in high-performance applications that require high reliability and accuracy.

Handling and Processing Rogers RO3006

Machining

Rogers RO3006 is a high-performance circuit board material that requires careful handling and processing to achieve optimal results. The material can be machined using standard CNC equipment, but it is important to use the correct cutting tools and parameters to ensure a clean and precise cut. Carbide or diamond-coated tools are recommended for machining RO3006, and the cutting speed should be kept low to prevent excessive heat buildup and material deformation.

Drilling

When drilling RO3006, it is important to use a high-speed drill bit with a sharp point and a low helix angle. The drill speed should be kept low to prevent excessive heat buildup and material deformation, and the drill bit should be lubricated with a suitable coolant to reduce friction and prevent chip buildup. It is also important to use a drill press or other precision drilling equipment to ensure accurate hole placement and size.

Mounting

To mount RO3006, it is recommended to use a high-quality adhesive or mechanical fasteners. The material is compatible with a wide range of adhesives, including epoxy, acrylic, and cyanoacrylate, but it is important to choose an adhesive that is appropriate for the specific application and operating conditions. Mechanical fasteners such as screws or bolts can also be used to mount RO3006, but care should be taken to avoid over-tightening or damaging the material.

In summary, handling and processing Rogers RO3006 requires careful attention to detail and the use of appropriate tools and techniques. Machining should be done with carbide or diamond-coated tools at a low cutting speed, drilling should be done with a high-speed drill bit and lubricant, and mounting can be done with adhesives or mechanical fasteners. With proper handling and processing, RO3006 can deliver high-performance results in a variety of circuit board applications.

Comparative Analysis

When it comes to high-frequency circuit board materials, Rogers RO3006 is often compared to other popular materials like FR-4 and PTFE. Here, we will take a closer look at how Rogers RO3006 compares to these materials.

Dielectric Constant

One of the most important factors to consider when comparing circuit board materials is their dielectric constant, which is a measure of how much a material can store electric charge. Rogers RO3006 has a dielectric constant of 6.15, making it a good choice for applications that require high signal integrity and low loss.

In comparison, FR-4 has a dielectric constant of around 4.5, which is lower than that of Rogers RO3006. PTFE, on the other hand, has a dielectric constant of around 2.1, which is significantly lower than both Rogers RO3006 and FR-4. This makes PTFE an ideal choice for applications that require very low loss.

Thermal Conductivity

Another important factor to consider is thermal conductivity, which is a measure of how well a material can transfer heat. Rogers RO3006 has a thermal conductivity of 0.8 W/mK, which is higher than that of FR-4 (around 0.2 W/mK) but lower than that of PTFE (around 0.3 W/mK).

Cost

Cost is also an important factor to consider when choosing a circuit board material. Rogers RO3006 is generally more expensive than FR-4 but less expensive than PTFE. However, the higher cost of Rogers RO3006 may be worth it for applications that require high signal integrity and low loss.

Conclusion

Overall, Rogers RO3006 offers a good balance of dielectric constant, thermal conductivity, and cost, making it a popular choice for high-frequency circuit board applications. However, the best choice of material will ultimately depend on the specific needs of each application.

Conclusion

Rogers RO3006 is a high-performance material that has been engineered to meet the demanding requirements of high-frequency applications. This material is widely used in the RF and microwave industry due to its excellent electrical properties, low dielectric loss, and high thermal stability.

During our research, we found that Rogers RO3006 offers superior performance in terms of insertion loss, signal integrity, and reliability. It is a cost-effective solution for high-frequency applications that require low loss and high reliability.

In addition, Rogers RO3006 has excellent mechanical properties, making it easy to fabricate and assemble. It is compatible with standard printed circuit board (PCB) fabrication processes, including drilling, plating, and etching.

Overall, Rogers RO3006 is an excellent choice for high-frequency applications that require low loss, high reliability, and excellent electrical performance. With its superior performance and ease of use, it is no wonder that it is a preferred choice for many designers and manufacturers in the RF and microwave industry.

Leave a Reply