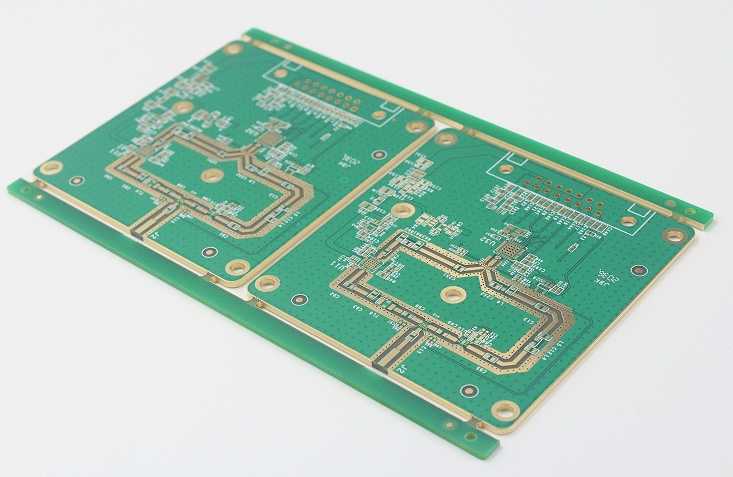

Substrate materials, DBC and Carriers for reliable power electronics

Rogers curamik Thermal is a leading manufacturer of high-performance thermal management solutions for power electronics. They offer a wide range of substrate materials, direct bonded copper (DBC) and carriers to meet the demanding thermal requirements of modern power electronic systems and modules.

Substrate Materials

Rogers curamik Thermal offers several families of substrate materials including:

- curamik AlN – Aluminum nitride substrates with high thermal conductivity.

- curamik ZL – Composite ceramic substrates with thermal expansion similar to silicon.

- curamik AMB – Active metal brazed substrates.

- curamik ELT – Extremely low temperature co-fired ceramic substrates.

These substrate materials are known for their excellent thermal conductivity, electrical isolation, and coefficient of thermal expansion (CTE) match to various chip materials. By combining different substrate materials in a hybrid configuration, Rogers curamik enables optimized thermal management solutions.

Aluminum Nitride Substrates

Aluminum nitride (AlN) substrates have the highest thermal conductivity among ceramic materials. Key properties:

- Thermal conductivity: 180 – 220 W/mK

- High electrical resistivity

- Low dielectric constant

- Excellent corrosion resistance

- CTE: 4.5 ppm/K

AlN substrates are ideal for high-power applications with extreme heat dissipation requirements. Rogers curamik AlN substrates are available in single-layer and multi-layer configurations.

Direct Bonded Copper (DBC)

Rogers curamik offers several DBC material systems suitable for various applications:

- curamik DBC-C – Copper on AlN ceramic

- curamik DBC-Si – Copper on Al2O3 ceramic

- curamik DBC-Cu – Copper on CuMo composite

These DBC substrates provide outstanding thermal conductivity and electrical isolation. The direct bond between copper and ceramic achieves high thermal cycling stability. Rogers curamik’s DBC materials are designed to withstand extreme thermal, mechanical and electrical loads in high-power modules.

Copper on AlN DBC

The curamik DBC-C system pairs high purity copper with AlN ceramic substrate. Key properties:

- Outstanding thermal performance

- Thermal conductivity up to 220 W/mK

- High dielectric strength >11 kV/mm

- Hermetic seal

Its excellent thermal, electrical and mechanical properties make curamik DBC-C suitable for IGBT power modules, automotive power electronics and other demanding applications.

Carriers

Rogers curamik offers power module carriers in AlSiC and CuMo composite materials. These carriers are used as baseplates for power modules to enable electrical isolation while providing thermal conduction away from the modules. Key benefits:

- High thermal conductivity

- Low CTE for reliability

- Electrically isolating

- Weight reduction potential

By optimizing carrier materials for specific applications, Rogers curamik enables reduced weight, improved reliability and lower system costs.

AlSiC Carriers

AlSiC carriers consist of aluminum matrix infused with silicon carbide particles. This composite material offers an excellent combination of properties:

- Thermal conductivity: 170 – 220 W/mK

- High strength and stiffness

- Low density: ~3 g/cm3

- CTE tunable to DBC substrate

- Electrically isolating

AlSiC carriers are ideal for aerospace, defense, and other applications where weight reduction and thermal performance are critical.

Conclusion

Rogers curamik Thermal provides customized thermal management solutions to meet the specific needs of power electronic systems and modules. Their extensive material and design expertise enables high-performance, reliable substrates, DBC and carriers for demanding applications.

Frequently Asked Questions

Q: What industries use Rogers curamik Thermal products?

A: Key industries using Rogers curamik Thermal products include automotive, aerospace, industrial, renewable energy, rail and defense. Their substrate materials, DBC and carriers are designed to withstand extreme environments.

Q: How are Rogers curamik substrates different from traditional ceramic substrates?

A: Rogers curamik uses advanced ceramic materials like AlN and AlSiC composites to achieve much higher thermal conductivity than traditional ceramics. Their materials are engineered specifically for thermal management.

Q: What fabrication capabilities does Rogers curamik offer?

A: Rogers curamik has extensive fabrication capabilities including cutting, milling, metallization, printing, cleaning, brazing and more. This allows them to produce finished components and assemblies.

Q: Does Rogers curamik provide custom designs?

A: Yes, Rogers curamik works closely with customers to engineer thermal management solutions tailored to their specific application requirements. Their expert design services can create custom substrates, DBC and carriers.

Q: Where is Rogers curamik located?

A: Rogers curamik has manufacturing facilities in Germany, Poland, China, Korea and the United States to serve customers worldwide. They have sales support and technical services across the major regions.

Leave a Reply