Introduction to PCB Materials

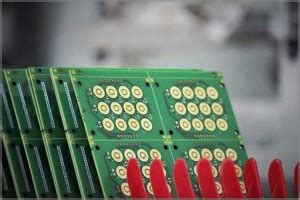

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They provide a platform for mounting and interconnecting electronic components, enabling the creation of complex circuits and devices. The choice of materials used in the construction of PCBs plays a crucial role in determining their performance, reliability, and durability. In this comprehensive article, we will explore the various materials used in PCB Fabrication, their properties, and their applications.

Types of PCB Materials

1. Substrate Materials

The substrate is the foundation of a PCB, providing mechanical support and electrical insulation for the copper traces and components. The most commonly used substrate materials are:

a. FR-4

FR-4 is a composite material made of woven fiberglass cloth impregnated with an epoxy resin. It is the most widely used substrate material due to its excellent mechanical and electrical properties, as well as its cost-effectiveness. FR-4 offers good insulation, high resistance to heat and moisture, and acceptable dielectric constant and loss tangent values.

b. High-Frequency Laminates

For applications requiring higher frequencies and lower signal losses, specialized substrate materials are used. These include:

- Rogers RO4000 Series: These materials offer low dielectric constant and loss tangent values, making them suitable for high-frequency applications such as wireless communications and radar systems.

- PTFE (Polytetrafluoroethylene): PTFE-based laminates, such as Rogers RT/duroid, provide excellent electrical performance at high frequencies, with very low dielectric constant and loss tangent values. They are used in demanding RF and microwave applications.

c. Flexible Substrates

Flexible PCBs require substrates that can withstand repeated bending and flexing without damage. Common flexible substrate materials include:

- Polyimide (PI): Polyimide films, such as DuPont Kapton, offer excellent flexibility, high temperature resistance, and good electrical properties. They are widely used in flexible and Flex-Rigid PCBs.

- Polyester (PET): Polyester films, such as DuPont Mylar, are used in low-cost flexible PCBs for applications that do not require high temperature resistance.

2. Conductive Materials

The conductive traces on a PCB are typically made of copper, which is chosen for its excellent electrical conductivity, thermal conductivity, and ease of processing. There are two main types of copper used in PCBs:

a. Electrodeposited Copper (ED Copper)

ED copper is the most common type of copper used in PCBs. It is deposited onto the substrate through an electroplating process, resulting in a thin, uniform layer of copper. ED copper is cost-effective and provides good adhesion to the substrate.

b. Rolled Annealed Copper (RA Copper)

RA copper is a higher-quality alternative to ED copper. It is produced by rolling and annealing high-purity copper foils, resulting in a more uniform grain structure and better mechanical properties. RA copper offers higher conductivity and better resistance to thermal stress compared to ED copper.

3. Solder Mask Materials

Solder mask is a protective layer applied over the copper traces on a PCB, leaving only the exposed pads and connection points for soldering. The most common solder mask materials are:

a. Liquid Photoimageable Solder Mask (LPISM)

LPISM is a photopolymer material that is applied as a liquid and then exposed to UV light through a photomask to define the desired pattern. It offers good resolution, excellent adhesion, and high resistance to chemicals and heat.

b. Dry Film Solder Mask (DFSM)

DFSM is a solid photopolymer film that is laminated onto the PCB surface and then exposed to UV light through a photomask. It provides consistent thickness, good resolution, and ease of application, making it suitable for high-volume production.

4. Surface Finish Materials

The surface finish is applied to the exposed copper pads on a PCB to protect them from oxidation and enhance solderability. The most common surface finish materials are:

a. Hot Air Solder Leveling (HASL)

HASL is a widely used surface finish that involves dipping the PCB in molten solder and then using hot air to level the solder on the pads. It provides good solderability and is cost-effective, but can result in uneven surface flatness.

b. Electroless Nickel Immersion Gold (ENIG)

ENIG is a two-layer surface finish consisting of a thin layer of gold over a layer of nickel. The nickel layer provides a diffusion barrier and the gold layer offers excellent solderability and corrosion resistance. ENIG is widely used in high-reliability applications.

c. Immersion Silver (ImAg)

ImAg is a single-layer surface finish that deposits a thin layer of silver onto the copper pads. It provides good solderability, low cost, and flat surface finish, making it suitable for fine-pitch components.

d. Immersion Tin (ISn)

ISn is another single-layer surface finish that deposits a thin layer of tin onto the copper pads. It offers good solderability, low cost, and compatibility with lead-free soldering processes.

Properties of PCB Materials

The choice of PCB materials depends on various properties that affect the performance and reliability of the final product. Some of the key properties to consider are:

1. Dielectric Constant (Dk)

The dielectric constant is a measure of a material’s ability to store electrical energy. A lower Dk value indicates less energy storage and faster signal propagation, which is desirable for high-frequency applications.

2. Loss Tangent (Df)

The loss tangent, also known as the dissipation factor, is a measure of a material’s ability to dissipate electrical energy as heat. A lower Df value indicates less energy loss and better signal integrity.

3. Thermal Conductivity

Thermal conductivity is a measure of a material’s ability to conduct heat. Higher thermal conductivity allows for better heat dissipation, which is crucial for high-power applications and thermal management.

4. Coefficient of Thermal Expansion (CTE)

The CTE is a measure of a material’s expansion or contraction with changes in temperature. A lower CTE value indicates better dimensional stability and less stress on components during temperature fluctuations.

5. Mechanical Strength

Mechanical strength is important for the durability and reliability of PCBs. Materials with high tensile strength, flexural strength, and impact resistance are preferred for applications that involve mechanical stress.

Applications of PCB Materials

The choice of PCB materials depends on the specific requirements of the application. Some common applications and their material requirements are:

1. Consumer Electronics

Consumer electronics, such as smartphones, tablets, and laptops, require cost-effective materials with good electrical and mechanical properties. FR-4 substrates, ED copper, and HASL or ImAg surface finishes are commonly used.

2. Automotive Electronics

Automotive electronics require materials that can withstand harsh environmental conditions, such as high temperatures, vibrations, and moisture. High-Tg FR-4 substrates, RA copper, and ENIG surface finish are often used for their reliability and durability.

3. Industrial Electronics

Industrial electronics, such as process control systems and power electronics, require materials with high thermal conductivity and mechanical strength. Aluminum-backed PCBs, thick copper layers, and ENIG surface finish are commonly used.

4. Medical Electronics

Medical electronics require materials that are biocompatible, reliable, and resistant to sterilization processes. Polyimide substrates, RA copper, and ENIG surface finish are often used for their stability and durability.

5. High-Frequency and RF Applications

High-frequency and RF applications, such as wireless communications and radar systems, require materials with low dielectric constant and loss tangent values. High-frequency laminates, such as Rogers RO4000 series, PTFE-based laminates, and RA copper, are commonly used.

PCB Material Selection Criteria

When selecting PCB materials, several criteria should be considered to ensure the best performance and reliability for the specific application. These criteria include:

- Electrical Requirements

- Dielectric constant

- Loss tangent

- Impedance control

-

Signal integrity

-

Thermal Requirements

- Operating temperature range

- Thermal conductivity

-

Coefficient of thermal expansion

-

Mechanical Requirements

- Flexural strength

- Tensile strength

- Impact resistance

-

Dimensional stability

-

Environmental Requirements

- Moisture resistance

- Chemical resistance

- UV resistance

-

Flammability rating

-

Manufacturing Requirements

- Ease of processing

- Compatibility with fabrication processes

- Cost-effectiveness

- Lead time and availability

By considering these criteria and evaluating the specific needs of the application, designers can select the most suitable PCB materials to ensure optimal performance and reliability.

PCB Material Comparison

| Material Property | FR-4 | Rogers RO4350B | Polyimide | Aluminum |

|---|---|---|---|---|

| Dielectric Constant (Dk) | 4.5 | 3.48 | 3.5 | – |

| Loss Tangent (Df) | 0.02 | 0.0037 | 0.002 | – |

| Thermal Conductivity (W/mK) | 0.3 | 0.6 | 0.2 | 150 |

| CTE (ppm/°C) | 15 | 10 | 20 | 23 |

| Tg (°C) | 130-140 | >280 | >250 | – |

| Moisture Absorption (%) | 0.1-0.2 | 0.06 | 0.4-0.8 | – |

This table compares the key properties of some common PCB materials, including FR-4, Rogers RO4350B (high-frequency laminate), polyimide (flexible substrate), and aluminum (metal-backed PCB). It helps designers understand the differences between these materials and select the most appropriate one based on the application requirements.

Future Trends in PCB Materials

As electronics continue to advance, there is a growing demand for PCB materials that can meet the ever-increasing performance requirements. Some of the future trends in PCB materials include:

- Advanced Composite Materials

- Development of new composite materials with improved electrical, thermal, and mechanical properties

-

Integration of nanomaterials, such as carbon nanotubes and graphene, to enhance performance

-

Eco-Friendly Materials

- Increasing adoption of halogen-free and lead-free materials to reduce environmental impact

-

Development of biodegradable and recyclable PCB materials

-

3D Printing Materials

- Exploration of 3D printable conductive and dielectric materials for rapid prototyping and customization

-

Development of multi-material 3D printing techniques for integrated electronics fabrication

-

High-Speed and High-Frequency Materials

- Continuous improvement of low-loss and low-Dk materials for high-speed digital and RF applications

-

Development of materials with improved thermal conductivity and dimensional stability for better signal integrity

-

Flexible and Stretchable Materials

- Advancement of flexible and stretchable substrate materials for wearable electronics and IoT devices

- Integration of conductive inks and elastomeric materials for enhanced flexibility and durability

By staying up-to-date with these trends and adopting new materials as they become available, designers can create PCBs that meet the evolving needs of modern electronics.

Frequently Asked Questions (FAQ)

- What is the most commonly used PCB substrate material?

-

The most commonly used PCB substrate material is FR-4, which is a composite of woven fiberglass cloth and epoxy resin. FR-4 offers a good balance of electrical, mechanical, and thermal properties, as well as cost-effectiveness.

-

What are the advantages of using high-frequency laminates in PCBs?

-

High-frequency laminates, such as Rogers RO4000 series and PTFE-based materials, offer lower dielectric constant and loss tangent values compared to standard FR-4. This results in reduced signal loss, improved signal integrity, and better performance at high frequencies, making them suitable for wireless communications, radar systems, and other RF applications.

-

What is the difference between ED copper and RA copper?

-

ED (Electrodeposited) copper is the most common type of copper used in PCBs, which is deposited onto the substrate through an electroplating process. RA (Rolled Annealed) copper, on the other hand, is produced by rolling and annealing high-purity copper foils, resulting in a more uniform grain structure and better mechanical properties. RA copper offers higher conductivity and better resistance to thermal stress compared to ED copper.

-

What factors should be considered when selecting a surface finish for PCBs?

-

When selecting a surface finish for PCBs, several factors should be considered, including:

- Solderability: The ability of the surface finish to provide good wetting and bonding with solder

- Shelf life: The duration for which the surface finish can maintain its solderability and prevent oxidation

- Flatness: The uniformity and planarity of the surface finish, which is important for fine-pitch components

- Compatibility: The compatibility of the surface finish with the chosen soldering process and components

- Cost: The cost-effectiveness of the surface finish in relation to the application requirements

-

How do flexible PCB materials differ from rigid PCB materials?

- Flexible PCB materials, such as polyimide (PI) and polyester (PET), are designed to withstand repeated bending and flexing without damage. They offer high flexibility, good electrical properties, and resistance to high temperatures. In contrast, rigid PCB materials, such as FR-4, provide a stable and rigid platform for mounting components but have limited flexibility. Flexible PCBs are used in applications that require conformity to curved surfaces or dynamic motion, while rigid PCBs are used in applications that demand structural stability and high component density.

Conclusion

In conclusion, the selection of PCB materials plays a crucial role in determining the performance, reliability, and durability of electronic devices. Understanding the properties and characteristics of various substrate materials, conductive materials, solder mask materials, and surface finishes is essential for designing PCBs that meet the specific requirements of different applications.

By considering factors such as dielectric constant, loss tangent, thermal conductivity, mechanical strength, and environmental resistance, designers can make informed decisions when choosing PCB materials. Additionally, staying updated with future trends in PCB materials, such as advanced composites, eco-friendly options, and high-speed and high-frequency materials, can help designers create PCBs that keep pace with the ever-evolving needs of modern electronics.

As the demand for high-performance, reliable, and cost-effective PCBs continues to grow, the development and adoption of new materials will play a vital role in shaping the future of the electronics industry. By leveraging the right PCB materials and staying at the forefront of technological advancements, designers can create innovative and robust electronic devices that meet the challenges of tomorrow.

Leave a Reply