Introduction to IC Block Removal

Integrated Circuit (IC) blocks are essential components of Printed Circuit Boards (PCBs) that perform various functions in electronic devices. However, there may be instances when you need to remove an IC block from a PCB, such as for replacement, repair, or salvaging purposes. Removing an IC block requires careful handling and the right techniques to avoid damaging the PCB or the IC block itself.

In this comprehensive guide, we will walk you through the step-by-step process of removing an IC block from a PCB safely and efficiently. We will cover the necessary tools, precautions, and methods to ensure a successful IC block removal.

Tools and Materials Required for IC Block Removal

Before diving into the IC block removal process, it’s essential to gather the necessary tools and materials. Having the right equipment will make the task easier and minimize the risk of damage. Here’s a list of the tools and materials you’ll need:

| Tool/Material | Purpose |

|---|---|

| Soldering iron | To melt the solder and remove the IC block |

| Desoldering pump or solder sucker | To remove the melted solder from the PCB |

| Desoldering braid or wick | An alternative to the desoldering pump for removing solder |

| Tweezers | To handle small components and remove the IC block |

| Flux | To improve solder flow and prevent oxidation |

| Isopropyl alcohol | To clean the PCB after IC block removal |

| Safety glasses | To protect your eyes from solder splashes |

| Antistatic mat or wrist strap | To prevent electrostatic discharge (ESD) damage |

Make sure you have all the necessary tools and materials before starting the IC block removal process.

Precautions and Safety Measures

Removing an IC block from a PCB involves working with hot soldering irons and handling delicate components. It’s crucial to take the following precautions and safety measures to ensure a safe and successful removal process:

-

Wear safety glasses: Always wear safety glasses to protect your eyes from solder splashes or accidental debris.

-

Use an antistatic mat or wrist strap: IC blocks and PCBs are sensitive to electrostatic discharge (ESD). Use an antistatic mat or wear an antistatic wrist strap to prevent ESD damage.

-

Work in a well-ventilated area: Soldering releases fumes that can be harmful if inhaled. Ensure proper ventilation in your work area or use a fume extractor.

-

Handle the PCB and IC block with care: PCBs and IC blocks are delicate components. Handle them gently to avoid physical damage, such as bending or breaking.

-

Allow the soldering iron to cool down: After using the soldering iron, let it cool down completely before storing it away to prevent accidental burns or fires.

Step-by-Step Guide to Removing the IC Block

Now that you have the necessary tools and have taken the proper precautions, let’s dive into the step-by-step process of removing the IC block from the PCB.

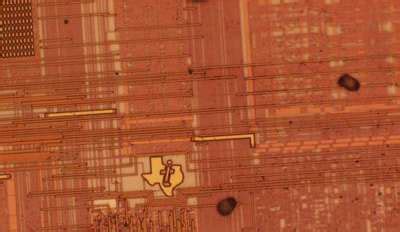

Step 1: Identify the IC Block

The first step is to identify the IC block you want to remove. Refer to the PCB schematic or documentation to locate the specific IC block. Take note of its orientation and pinout to ensure proper removal and reinstallation if needed.

Step 2: Clean the PCB

Before starting the removal process, clean the area around the IC block on the PCB. Use isopropyl alcohol and a soft brush or cloth to remove any dust, dirt, or residue. A clean surface will make the removal process easier and more efficient.

Step 3: Apply Flux

Apply a small amount of flux to the solder joints of the IC block. Flux helps improve solder flow, prevents oxidation, and makes it easier to remove the solder. Use a flux pen or a small brush to apply the flux precisely on the solder joints.

Step 4: Heat the Solder Joints

Turn on your soldering iron and let it heat up to the appropriate temperature. The temperature setting depends on the type of solder used on the PCB. Refer to the solder manufacturer’s guidelines for the recommended temperature.

Once the soldering iron is heated, gently touch the tip to each solder joint of the IC block. Apply heat to the joint for a few seconds until the solder melts and becomes shiny. Be careful not to apply too much heat, as it can damage the PCB or the IC block.

Step 5: Remove the Solder

While the solder is still molten, use a desoldering pump or solder sucker to remove the solder from the joint. Place the tip of the desoldering pump near the molten solder and release the plunger to suck up the solder.

Alternatively, you can use desoldering braid or wick to remove the solder. Place the braid on the molten solder and apply heat with the soldering iron. The braid will absorb the solder, leaving the joint clean.

Repeat this process for all the solder joints of the IC block.

Step 6: Remove the IC Block

Once you have removed the solder from all the joints, gently lift the IC block from the PCB using tweezers. Be careful not to apply too much force, as it can damage the PCB pads or the IC block itself.

If the IC block is still stuck, apply a small amount of additional heat to the remaining solder joints while gently lifting the IC block. Avoid prying or forcing the IC block, as it can cause damage.

Step 7: Clean the PCB

After removing the IC block, clean the PCB pads and surrounding area with isopropyl alcohol and a soft brush or cloth. Remove any remaining solder, flux residue, or debris to ensure a clean surface for future use.

Step 8: Inspect the PCB and IC Block

Inspect the PCB pads and the IC block for any signs of damage, such as lifted pads, broken pins, or cracks. If you notice any damage, assess whether it can be repaired or if replacement is necessary.

Tips and Tricks for Successful IC Block Removal

Here are some additional tips and tricks to help you achieve successful IC block removal:

-

Use the right soldering iron tip: Choose a soldering iron tip that matches the size of the solder joints. A tip that is too large can damage the PCB, while a tip that is too small may not effectively melt the solder.

-

Apply the right amount of heat: Apply just enough heat to melt the solder without overheating the PCB or the IC block. Excessive heat can cause damage and make the removal process more difficult.

-

Work patiently and methodically: Take your time and work methodically to remove the solder from each joint. Rushing the process can lead to mistakes and potential damage.

-

Practice on scrap PCBs: If you are new to IC block removal, practice on scrap PCBs or old electronic devices to get a feel for the process before working on your main project.

-

Use magnification: If the IC block and solder joints are small, use magnification tools like a magnifying glass or a microscope to ensure precision and accuracy.

Frequently Asked Questions (FAQ)

- Can I reuse the IC block after removing it from the PCB?

-

It depends on the condition of the IC block after removal. If the IC block is undamaged and the pins are intact, it may be possible to reuse it. However, if there are any signs of damage or if the IC block has been exposed to excessive heat, it’s best to use a new one to ensure reliability.

-

What should I do if I accidentally damage the PCB pads while removing the IC block?

-

If the PCB pads are slightly lifted or damaged, you may be able to repair them using conductive epoxy or by carefully soldering a small wire to bridge the connection. However, if the damage is severe, you may need to replace the PCB or seek professional repair services.

-

Can I use a heat gun instead of a soldering iron to remove the IC block?

-

While a heat gun can be used to remove IC blocks, it is not recommended for precise removal. Heat guns apply heat over a larger area and can potentially damage nearby components. A soldering iron provides more controlled and localized heat, making it the preferred tool for IC block removal.

-

How do I identify the orientation of the IC block for reinstallation?

-

Most IC blocks have a notch, dot, or other markings that indicate the orientation. Refer to the IC block’s datasheet or the PCB schematic to determine the correct orientation. It’s crucial to install the IC block in the correct orientation to avoid damage and ensure proper functionality.

-

What should I do with the removed IC block and solder waste?

- Dispose of the removed IC block and solder waste properly. IC blocks may contain hazardous materials and should be disposed of in accordance with local electronic waste regulations. Solder waste, including used desoldering braid and solder debris, should also be disposed of responsibly to prevent environmental contamination.

Conclusion

Removing an IC block from a PCB requires patience, precision, and the right tools and techniques. By following the step-by-step guide outlined in this article and taking the necessary precautions, you can successfully remove an IC block without damaging the PCB or the component itself.

Remember to work methodically, apply the appropriate amount of heat, and handle the PCB and IC block with care. If you encounter any challenges or are unsure about the process, don’t hesitate to seek guidance from experienced professionals or refer to additional resources.

With practice and experience, IC block removal will become a more manageable task, allowing you to repair, replace, or salvage components from PCBs with confidence. Happy soldering!

Leave a Reply