Introduction

Desoldering is the process of removing solder from a circuit board hole, which is an essential skill for anyone involved in electronics repair or modification. Whether you need to replace a faulty component, modify a circuit, or salvage parts from an old board, knowing how to properly desolder a hole is crucial. In this comprehensive guide, we will cover everything you need to know about desoldering holes on a circuit board, including the tools and techniques required, step-by-step instructions, and helpful tips to ensure success.

What is Desoldering?

Desoldering is the opposite of soldering. While soldering involves melting solder to create an electrical connection between components and the circuit board, desoldering involves removing the solder to disconnect components or clear a hole for a new connection. Desoldering is necessary when replacing faulty components, modifying circuits, or salvaging parts from old boards.

Why Desolder a Hole?

There are several reasons why you might need to desolder a hole on a circuit board:

-

Component replacement: If a component on the board is faulty or needs to be upgraded, you will need to desolder it from the board before installing a new one.

-

Circuit modification: Sometimes, you may need to modify a circuit by adding or removing components. Desoldering allows you to clear the necessary holes for these changes.

-

Part salvage: If you have an old or broken circuit board, you may want to salvage usable components for future projects. Desoldering is necessary to remove these components from the board.

-

Repair work: Desoldering is often required during repair work, such as fixing broken traces or removing short circuits.

Tools Required for Desoldering

To effectively desolder a hole on a circuit board, you will need the following tools:

-

Soldering iron: A soldering iron is the most essential tool for desoldering. Choose a high-quality, temperature-controlled soldering iron with a fine tip for precision work.

-

Desoldering pump (solder sucker): A desoldering pump, also known as a solder sucker, is a spring-loaded device that quickly sucks up molten solder from a hole.

-

Desoldering braid (solder wick): Desoldering braid, or solder wick, is a copper braid that absorbs molten solder when placed on a heated joint.

-

Tweezers: Fine-tipped tweezers are useful for handling small components and cleaning debris from the board.

-

Solder: Having some fresh solder on hand can be helpful for adding to a joint to make it easier to remove.

-

Safety equipment: Always wear safety glasses and work in a well-ventilated area to protect yourself from solder fumes.

| Tool | Purpose |

|---|---|

| Soldering iron | Melts solder for removal |

| Desoldering pump | Sucks up molten solder |

| Desoldering braid | Absorbs molten solder |

| Tweezers | Handles small components and debris |

| Solder | Adds to joint for easier removal |

| Safety equipment | Protects from solder fumes and debris |

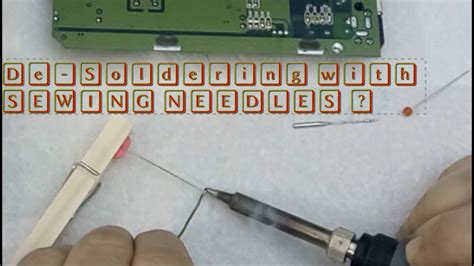

Step-by-Step Guide to Desoldering a Hole

Follow these steps to successfully desolder a hole on a circuit board:

Step 1: Prepare Your Workspace

- Ensure your workspace is clean, well-lit, and well-ventilated.

- Gather all the necessary tools and materials.

- Secure the circuit board using a PCB holder or a helping hand tool.

Step 2: Clean the Area

- Remove any dirt, dust, or debris from the area around the hole using tweezers or a soft brush.

- If the hole is filled with old solder, add a small amount of fresh solder to the joint to help the old solder melt more easily.

Step 3: Heat the Joint

- Set your soldering iron to the appropriate temperature (typically between 300°C and 400°C).

- Place the tip of the soldering iron on the joint, making sure it contacts both the component lead and the solder pad.

- Hold the iron in place for a few seconds until the solder melts completely.

Step 4: Remove the Solder

Using a Desoldering Pump

- Prime the desoldering pump by pushing the plunger down until it locks.

- Position the nozzle of the pump close to the molten solder, without touching the soldering iron tip.

- Release the plunger to suck up the molten solder. Repeat if necessary.

Using Desoldering Braid

- Place the desoldering braid on top of the molten solder.

- Press the soldering iron tip onto the braid, allowing it to heat up and absorb the solder.

- Move the braid around the joint to absorb as much solder as possible.

Step 5: Clean the Hole

- Once most of the solder has been removed, use tweezers to remove any remaining debris or component leads from the hole.

- If necessary, use a small drill bit or a specialized desoldering tool to clear any stubborn solder from the hole.

Step 6: Inspect the Result

- Visually inspect the hole to ensure it is clean and free of solder and debris.

- Use a multimeter to check for continuity between the hole and its corresponding pad to ensure a successful desoldering process.

Tips for Successful Desoldering

-

Use the right tools: Invest in high-quality desoldering tools to make the process easier and more effective.

-

Apply the right amount of heat: Too little heat will make it difficult to remove the solder, while too much heat can damage the board or surrounding components.

-

Work quickly: Once the solder melts, remove it promptly to avoid damaging the board or components.

-

Keep the area clean: Regularly clean your workspace and tools to prevent contamination and ensure optimal results.

-

Practice proper safety: Always wear safety glasses and work in a well-ventilated area to protect yourself from solder fumes and debris.

Frequently Asked Questions (FAQ)

1. What temperature should I set my soldering iron to for desoldering?

A: The ideal temperature for desoldering depends on the type of solder and the components involved. Generally, a temperature between 300°C and 400°C is suitable for most desoldering tasks. Consult your solder’s documentation for specific recommendations.

2. Can I reuse the solder removed during desoldering?

A: While it is possible to reuse solder, it is not recommended. Desoldered solder may contain impurities and debris that can affect the quality of future soldering joints. It is best to use fresh solder for new connections.

3. How do I prevent damaging the circuit board while desoldering?

A: To minimize the risk of damage, use the correct tools and techniques, apply heat only as long as necessary, and work quickly once the solder melts. Avoid applying excessive force or heat, which can damage the board or surrounding components.

4. What should I do if the solder won’t come out of the hole?

A: If the solder is not coming out easily, try adding a small amount of fresh solder to the joint to help the old solder melt more efficiently. You can also use a specialized desoldering tool, such as a desoldering station or a heated tweezers, to remove stubborn solder.

5. Can I desolder surface-mounted components (SMDs)?

A: Yes, you can desolder SMDs, but it requires a different technique than Through-Hole components. To desolder SMDs, use a hot air rework station or a specialized SMD desoldering tool. Apply heat evenly to the component and its pads, then carefully lift the component away from the board using tweezers.

Conclusion

Desoldering is an essential skill for anyone involved in electronics repair, modification, or salvage. By following the steps outlined in this guide and using the right tools and techniques, you can safely and effectively remove solder from a circuit board hole. Remember to work carefully, apply heat judiciously, and always prioritize safety. With practice and patience, you’ll master the art of desoldering and be well-equipped to tackle a wide range of electronics projects.

Leave a Reply