Introduction to Wire-to-Board Connections

Connecting wires to circuit boards is a fundamental skill in electronics. Whether you’re building a simple project or working on a complex system, understanding how to properly connect wires to a circuit board is essential for ensuring reliable electrical connections and avoiding potential issues. In this comprehensive guide, we’ll dive into the various methods and best practices for making wire-to-board connections.

Understanding Circuit Boards and Wires

Before we delve into the specifics of wire-to-board connections, let’s briefly discuss circuit boards and wires.

Circuit Boards

A circuit board, also known as a printed circuit board (PCB), is a flat board made of insulating material, such as fiberglass or plastic, with conductive tracks etched onto its surface. These tracks, called traces, allow electrical current to flow between components mounted on the board. Circuit boards come in various sizes and complexity, ranging from simple single-layer boards to multi-layer boards with intricate designs.

Wires

Wires are conductive materials, typically made of copper, used to transmit electrical signals or power between components. They are insulated with a non-conductive material, such as plastic or rubber, to prevent short circuits and protect the copper core. Wires come in different gauges (thicknesses) and insulation ratings, depending on the application and current-carrying requirements.

Types of Wire-to-Board Connections

There are several methods for connecting wires to a circuit board, each with its own advantages and considerations. Let’s explore the most common types of wire-to-board connections.

Through-Hole Connections

Through-hole connections involve inserting the wire through a hole drilled in the circuit board and soldering it in place. This method provides a strong mechanical connection and is suitable for applications where the wire may be subject to stress or vibration.

Steps for Making Through-Hole Connections

- Strip the insulation from the end of the wire, exposing about 1/4 inch (6mm) of the copper core.

- Insert the stripped end of the wire through the designated hole on the circuit board.

- Bend the wire at a 90-degree angle to secure it in place.

- Apply solder to the connection point, ensuring a solid electrical and mechanical bond.

Surface Mount Connections

Surface mount connections involve soldering the wire directly to a pad or trace on the surface of the circuit board. This method is commonly used in modern electronics due to its space-saving nature and compatibility with automated assembly processes.

Steps for Making Surface Mount Connections

- Strip the insulation from the end of the wire, exposing about 1/8 inch (3mm) of the copper core.

- Tin the exposed wire by applying a small amount of solder to it.

- Place the tinned wire onto the designated pad or trace on the circuit board.

- Apply heat to the connection point using a soldering iron, allowing the solder to flow and create a secure bond.

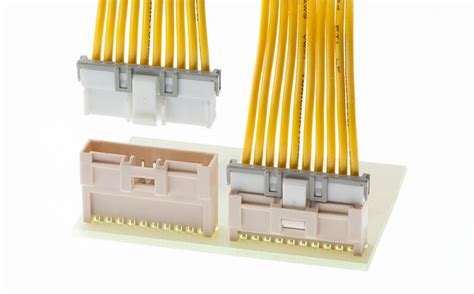

Crimped Connections

Crimped connections involve using a specialized tool called a crimping tool to attach a terminal or connector to the end of the wire. The terminal or connector is then inserted into a corresponding socket or header on the circuit board. This method provides a removable and reusable connection, making it ideal for prototyping or applications where wires may need to be disconnected and reconnected frequently.

Steps for Making Crimped Connections

- Strip the insulation from the end of the wire, exposing the appropriate length of the copper core based on the terminal or connector specifications.

- Insert the stripped end of the wire into the terminal or connector.

- Use a crimping tool to compress the terminal or connector around the wire, creating a secure mechanical and electrical connection.

- Insert the terminal or connector into the corresponding socket or header on the circuit board.

Best Practices for Wire-to-Board Connections

To ensure reliable and long-lasting wire-to-board connections, consider the following best practices:

Choosing the Right Wire Gauge

Select the appropriate wire gauge based on the current-carrying requirements of your application. Thicker wires (lower gauge numbers) can handle higher currents, while thinner wires (higher gauge numbers) are suitable for lower current applications. Refer to a wire gauge chart to determine the suitable gauge for your project.

Proper Insulation Stripping

When stripping the insulation from the wire, be careful not to nick or damage the copper core. Use a wire stripper tool with the appropriate gauge setting to ensure a clean and precise strip. Avoid using tools like scissors or knives, as they can easily damage the wire.

Soldering Techniques

Soldering is a crucial skill for making secure wire-to-board connections. Use a high-quality soldering iron with a clean, tinned tip. Apply heat to both the wire and the connection point on the circuit board, allowing the solder to flow evenly. Avoid using excessive solder, as it can create bulky connections and potentially cause short circuits.

Strain Relief

Provide strain relief for your wire-to-board connections to prevent excessive stress on the wires. This can be achieved by using cable ties, adhesive pads, or dedicated strain relief features on the circuit board. Proper strain relief helps maintain the integrity of the connections and reduces the risk of wires breaking or becoming disconnected.

Insulation and Protection

After making the wire-to-board connections, consider applying additional insulation or protective measures. Heat shrink tubing can be used to insulate exposed connections and provide a neat, professional appearance. Conformal coating or potting compounds can be applied to protect the connections from moisture, dust, or other environmental factors.

Common Challenges and Troubleshooting

Despite following best practices, you may encounter challenges when making wire-to-board connections. Here are some common issues and troubleshooting tips:

Cold Solder Joints

Cold solder joints occur when the solder fails to properly bond with the wire or the connection point on the circuit board. This can happen due to insufficient heat, improper soldering technique, or contaminated surfaces. To fix a cold solder joint, reheat the connection with a soldering iron and apply fresh solder if necessary.

Lifted Pads or Traces

Lifted pads or traces can occur when excessive force is applied to the wire or when the soldering iron is held in place for too long. If a pad or trace lifts from the circuit board, carefully scrape away the solder mask around the affected area and use a jumper wire to bridge the connection.

Short Circuits

Short circuits can happen when exposed wires or excessive solder inadvertently connects two or more points on the circuit board that should not be connected. To troubleshoot a short circuit, visually inspect the connections for any unintended bridges or contact between wires. Use a multimeter to test for continuity between suspected points.

Advanced Wire-to-Board Connection Techniques

As you gain experience with wire-to-board connections, you may come across more advanced techniques and considerations. Here are a few examples:

Multi-Conductor Cables

When working with multi-conductor cables, such as ribbon cables or shielded cables, you may need to use specialized connectors or termination techniques. IDC (Insulation Displacement Connector) and D-Sub connectors are commonly used for multi-conductor cable connections. Follow the manufacturer’s guidelines for proper termination and assembly.

High-Frequency Signals

For applications involving high-frequency signals, such as radio frequency (RF) or high-speed digital signals, special considerations must be taken to maintain signal integrity. Use appropriate shielding techniques, such as coaxial cables or shielded twisted pair wires, to minimize interference and crosstalk. Follow proper grounding and termination practices to ensure optimal signal quality.

Flexible Circuit Boards

Flexible circuit boards, also known as flex PCBs, require special attention when making wire-to-board connections. Use flexible wire or stranded wire to accommodate the bending and flexing of the board. Apply strain relief techniques to prevent damage to the connections due to repeated flexing.

Frequently Asked Questions (FAQ)

-

What is the difference between through-hole and surface mount connections?

Through-hole connections involve inserting the wire through a hole in the circuit board and soldering it in place, while surface mount connections involve soldering the wire directly to a pad or trace on the surface of the board. -

How do I choose the right wire gauge for my project?

The choice of wire gauge depends on the current-carrying requirements of your application. Refer to a wire gauge chart to determine the appropriate gauge based on the maximum current expected in your circuit. -

Can I use any type of solder for wire-to-board connections?

It is recommended to use high-quality, lead-free solder specifically designed for electronics. Avoid using acid-core solder or plumbing solder, as they can damage the components and circuit board. -

How can I prevent short circuits when making wire-to-board connections?

To prevent short circuits, ensure that the exposed wires are properly stripped and trimmed to the appropriate length. Avoid using excessive solder, and visually inspect the connections for any unintended bridges or contact between wires. -

What should I do if a pad or trace lifts from the circuit board?

If a pad or trace lifts from the circuit board, carefully scrape away the solder mask around the affected area and use a jumper wire to bridge the connection. Be cautious not to damage the surrounding components or traces.

Conclusion

Connecting wires to a circuit board is a fundamental skill in electronics that requires attention to detail and proper techniques. By understanding the different types of wire-to-board connections, following best practices, and being aware of common challenges, you can create reliable and robust electrical connections in your projects.

Remember to choose the appropriate wire gauge, use proper soldering techniques, and provide strain relief and protection for your connections. As you gain experience, you may encounter more advanced techniques and considerations, such as working with multi-conductor cables, high-frequency signals, or flexible circuit boards.

With practice and patience, you’ll develop the skills and confidence to tackle wire-to-board connections in various applications, from simple hobby projects to complex electronic systems. Happy soldering!

Leave a Reply