What is a PCB?

A Printed Circuit Board, or PCB, is the backbone of modern electronic devices. It is a flat board made of insulating materials, such as fiberglass or composite epoxy, with conductive pathways etched or printed onto its surface. These pathways, known as traces, connect various electronic components, such as resistors, capacitors, and integrated circuits, to form a complete electrical circuit.

PCBs come in various types, depending on the number of layers and the specific manufacturing process used:

- Single-sided PCBs: These have conductive traces on only one side of the board.

- Double-sided PCBs: These have conductive traces on both sides of the board, allowing for more complex circuit designs and higher component density.

- Multi-layer PCBs: These consist of multiple layers of conductive traces separated by insulating layers, enabling even more complex circuits and higher component density.

The main advantages of using PCBs in electronic devices include:

- Compact size: PCBs allow for the miniaturization of electronic devices by enabling the dense packaging of components.

- Reliability: The robust construction of PCBs ensures stable electrical connections and minimizes the risk of short circuits or component failures.

- Cost-effectiveness: Mass production of PCBs is highly cost-effective compared to other wiring methods, such as point-to-point wiring.

- Consistency: PCBs ensure consistent performance across multiple units of the same device, as the manufacturing process is highly standardized and automated.

The Importance of PCB Quality and Reliability

In today’s fast-paced, technology-driven world, the quality and reliability of PCBs are more critical than ever. Electronic devices are becoming increasingly complex, with higher component densities and more demanding performance requirements. As a result, the PCBs that form the foundation of these devices must meet stringent quality standards to ensure optimal functionality and longevity.

Poor-quality PCBs can lead to a range of issues, including:

- Reduced device performance: Substandard PCBs may cause signal integrity issues, leading to slower data transmission, increased error rates, and overall reduced device performance.

- Premature device failure: Low-quality PCBs are more prone to manufacturing defects, such as poor soldering, incorrect trace widths, or inadequate insulation. These defects can cause components to fail prematurely, leading to device malfunction and costly repairs or replacements.

- Safety hazards: In extreme cases, poor-quality PCBs can pose safety risks, such as electrical fires or short circuits, which can damage the device and potentially harm users.

- Reputational damage: Companies that use substandard PCBs in their products risk damaging their reputation if the devices fail to perform as expected or experience frequent malfunctions.

To mitigate these risks and ensure the best possible performance and reliability, it is essential to source PCBs from reputable manufacturers who adhere to strict quality control standards and use high-quality materials and manufacturing processes.

Our Commitment to Quality

At our company, we have always been committed to providing our customers with the highest-quality PCBs. We understand the critical role that PCBs play in the performance and reliability of electronic devices, and we spare no effort in ensuring that our products meet or exceed industry standards.

Our quality assurance process begins with the selection of premium materials, including high-grade copper, advanced dielectric materials, and superior solder masks. We work closely with our suppliers to ensure consistent quality and timely delivery of these materials.

Our state-of-the-art manufacturing facilities are equipped with the latest technology and are staffed by highly skilled and experienced professionals. We employ a range of advanced manufacturing techniques, such as automated optical inspection (AOI), in-circuit testing (ICT), and Functional Testing, to ensure that every PCB we produce meets our rigorous quality standards.

Furthermore, we have implemented a comprehensive quality management system that covers every aspect of our operations, from product design and development to manufacturing, testing, and customer support. This system is based on the internationally recognized ISO 9001 standard, which provides a framework for continuous improvement and customer satisfaction.

The Benefits of Our Price Reduction

Our recent price reduction for PCBs is a testament to our ongoing efforts to optimize our manufacturing processes and strengthen our supplier relationships. By streamlining our operations and negotiating better terms with our suppliers, we have been able to reduce our production costs without compromising on quality.

This price reduction offers several significant benefits to our customers:

- Cost savings: Our customers can now enjoy high-quality PCBs at a lower price, enabling them to reduce their production costs and improve their profit margins.

- Increased competitiveness: With lower PCB costs, our customers can offer their products at more competitive prices, helping them to gain market share and grow their businesses.

- Enhanced value: Our price reduction allows our customers to get more value for their money, as they can now purchase superior-quality PCBs at a lower price point.

- Expanded design possibilities: With more affordable PCBs, our customers can explore more ambitious and innovative product designs, incorporating advanced features and functionalities that may have been cost-prohibitive before.

To illustrate the potential cost savings, consider the following example:

| PCB Type | Previous Price (per unit) | New Price (per unit) | Quantity | Total Savings |

|---|---|---|---|---|

| 4-layer PCB | $10.00 | $8.50 | 1,000 | $1,500 |

| 6-layer PCB | $15.00 | $12.75 | 500 | $1,125 |

| 8-layer PCB | $20.00 | $17.00 | 250 | $750 |

As the table shows, the price reduction can lead to significant cost savings, especially for larger order quantities. These savings can be reinvested into product development, marketing, or other areas of the business to drive growth and innovation.

Our Ongoing Commitment to Customer Satisfaction

While our price reduction is undoubtedly good news for our customers, it is just one aspect of our broader commitment to customer satisfaction. We understand that our success depends on the success of our customers, and we are dedicated to providing them with the support and services they need to thrive in today’s competitive marketplace.

In addition to our high-quality PCBs, we offer a range of value-added services to help our customers streamline their operations and accelerate their time-to-market. These services include:

- Design support: Our team of experienced PCB designers can work closely with customers to optimize their PCB layouts, ensuring optimal performance, manufacturability, and cost-effectiveness.

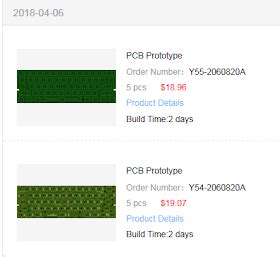

- Prototyping: We offer rapid prototyping services to help customers validate their designs and identify potential issues early in the development process, reducing the risk of costly delays or redesigns later on.

- Assembly services: We can provide full turnkey assembly services, including component sourcing, SMT and through-hole assembly, and final testing, allowing customers to focus on their core competencies while we handle the manufacturing process.

- Logistics support: We offer flexible shipping and logistics options to ensure that our customers receive their PCBs when and where they need them, minimizing inventory costs and reducing lead times.

Moreover, we are committed to building long-term partnerships with our customers based on trust, transparency, and mutual success. We believe in open and honest communication, and we are always ready to listen to our customers’ feedback and suggestions for improvement.

Frequently Asked Questions (FAQ)

- Q: How long will the price reduction last?

A: The price reduction is a permanent change to our pricing structure, reflecting our ongoing efforts to optimize our manufacturing processes and provide the best possible value to our customers. - Q: Will the price reduction affect the quality of the PCBs?

A: Absolutely not. We have achieved this price reduction through process improvements and stronger supplier partnerships, without compromising on the quality of our materials or manufacturing standards. - Q: Are the reduced prices available for all PCB types and quantities?

A: Yes, the price reduction applies to our entire range of PCBs, including single-sided, double-sided, and multi-layer boards, and across all order quantities. - Q: How can I place an order and take advantage of the new prices?

A: You can place an order through our website or by contacting our sales team directly. They will be happy to assist you with the ordering process and provide you with a detailed quote based on your specific requirements. - Q: What other services do you offer in addition to PCB manufacturing?

A: We offer a range of value-added services, including PCB design support, prototyping, assembly services, and logistics support. Our team is committed to providing comprehensive solutions to help our customers streamline their operations and achieve their business goals.

Conclusion

Our recent price reduction for PCBs is a significant milestone in our ongoing commitment to providing our customers with the best possible value and support. By optimizing our manufacturing processes and strengthening our supplier partnerships, we have been able to reduce our production costs without compromising on the quality or reliability of our products.

This price reduction offers numerous benefits to our customers, including cost savings, increased competitiveness, enhanced value, and expanded design possibilities. Moreover, it is just one aspect of our broader commitment to customer satisfaction, which includes high-quality products, value-added services, and long-term partnerships based on trust and transparency.

As we move forward, we will continue to invest in innovation, process improvement, and customer support to ensure that we remain at the forefront of the PCB Industry. We are excited about the opportunities that lie ahead and look forward to working closely with our customers to help them achieve their goals and succeed in today’s dynamic and challenging marketplace.

Leave a Reply