What is Duroid?

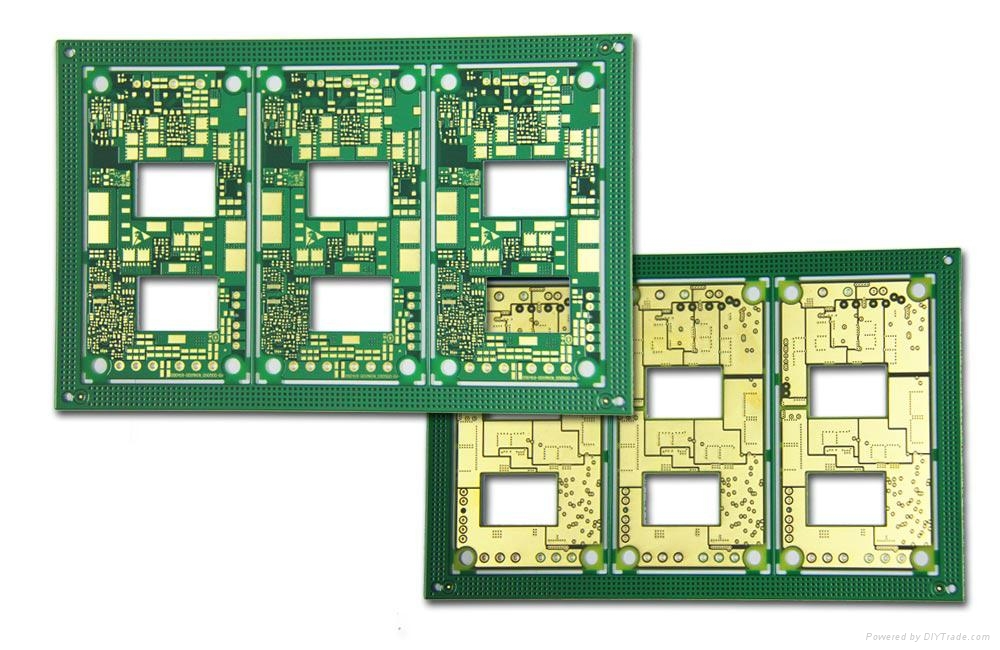

Duroid is a brand name for a family of high frequency dielectric materials manufactured by Rogers Corporation. These materials are some of the most widely used substrates for making printed circuit boards (PCBs) for microwave and mm-wave circuits and components.

Some key properties of Duroid materials:

- Stable dielectric constant over a wide frequency range

- Low dielectric loss

- Good thermal conductivity

- Excellent dimensional stability

- Easy to machine and fabricate

Duroid materials are available in many different dielectric formulations to suit various requirements and applications. Some popular versions include Duroid 5880, 5870, 6002 and 6010.

Applications of Duroid Materials

Duroid materials are ideal for designing:

- Microstrip and stripline circuits

- Patch antennas

- Slot antennas

- Filters and diplexers

- Mixers and detectors

- Oscillators and amplifiers

They are used in a wide variety of microwave systems and components, including:

- Radar and satellite communication systems

- Wireless infrastructure

- 5G cellular networks

- Automotive radars

- Aerospace and defense electronics

Manufacturing and Fabrication

Duroid materials are available as solid laminates or prepreg sheets. They can be easily machined, drilled, routed, punched and laser cut to make PCBs and components. The low shrinkage of Duroid results in excellent dimensional stability during PCB fabrication.

Duroid laminates bond well with electrodeposited and rolled copper foils. They can also be plated with gold, silver, nickel and tin-lead alloy for solderability. The materials can withstand soldering temperatures up to 288°C.

Modeling and Design

Accurate modeling of Duroid dielectrics is critical for optimal microwave circuit design. Rogers Corporation provides extensive property data for their materials, including frequency-dependent dielectric constant and loss tangent.

PCB design rules for Duroid are similar to FR-4 materials. Line width, spacing and thickness need to be adjusted to achieve 50Ω impedance with Duroid’s lower dielectric constant. Cross-sectional dimensions and models provided by Rogers should be used for simulations.

Key Takeaways

- Duroid materials offer stable, low-loss dielectric substrates for microwave frequencies

- Ideal for a wide range of microwave components and PCBs

- Easy to fabricate using standard PCB processes

- Excellent dimensional stability compared to other materials

- Extensive property data available for accurate modeling and simulations

Frequently Asked Questions

What are some commonly used Duroid materials and their applications?

Some common Duroid materials include:

- Duroid 5880 – Used for microwave components and PCBs up to 40 GHz

- Duroid 5870 – Optimized for mm-wave applications from 40-100 GHz

- Duroid 6002 – Lowest loss material, good for high Q circuits

- Duroid 6010 – Lowest dielectric constant material

How do Duroid materials compare to FR-4?

Duroid has much lower dielectric loss than FR-4, making it suitable for high frequency applications. It also has better thermal conductivity and dimensional stability. However, FR-4 is significantly lower cost than Duroid.

Can Duroid materials be used for flexible PCBs?

Yes, Rogers Corporation makes polyimide based flexible circuit materials under the Duroid brand, such as DuPont Pyralux AP. These provide similar electrical properties as rigid Duroid laminates.

What thickness of Duroid material is commonly used?

For microwave PCBs, common Duroid thicknesses are 20, 30 and 40 mils. For lower frequencies 10 mil thickness can be used. Thicker materials provide better power handling and thermal conductivity.

Does Rogers Corporation make pre-impregnated Duroid materials?

Yes, Rogers’ RT/duroid 6000 series materials are reinforced prepregs available in various dielectric formulations for fabricating multilayer boards using high temperature pressing.

Leave a Reply