Introduction

Duroid 5880 is a high-frequency, high-performance microwave laminate that is widely used in the production of printed circuit boards (PCBs) for radar, satellite communication, and other microwave applications. With its unique properties, Duroid 5880 enables reliable performance at microwave frequencies up to Ku-band and beyond.

Key Properties

Duroid 5880 stands out for its exceptional electrical and mechanical properties that make it ideal for high-frequency applications:

Low Loss

Duroid 5880 has a low dissipation factor (Df) of 0.0019 at 10 GHz, enabling excellent power handling with minimal signal loss. The low loss allows for improved signal integrity.

High Dielectric Constant

With a dielectric constant (Er) of 2.20 at 10 GHz, Duroid 5880 helps miniaturize circuit dimensions making it suitable for compact designs.

Excellent Dielectric Stability

The dielectric constant of Duroid 5880 remains stable over a wide frequency range (up to Ku-band), temperature range (-60°C to 100°C) and during exposure to high humidity. This stability prevents variations in circuit performance.

Good Thermal Conductivity

With a thermal conductivity of 0.71 W/m/K, Duroid 5880 promotes efficient heat dissipation from components mounted on it. This enhances reliability and lifetime.

Strong Peel Strength

The bond between laminate and copper cladding is durable with a minimum peel strength of 14.5 N/mm. This allows PCBs to withstand mechanical stress during assembly and use.

Applications

The unique properties of Duroid 5880 make it suitable for:

- Radar and satellite communication circuits

- Microwave radio links

- Missile guidance systems

- Microwave test equipment

- High-speed digital circuits

- Aerospace and aviation electronics

It can be used to produce single, double, and multilayer boards for various demanding microwave applications.

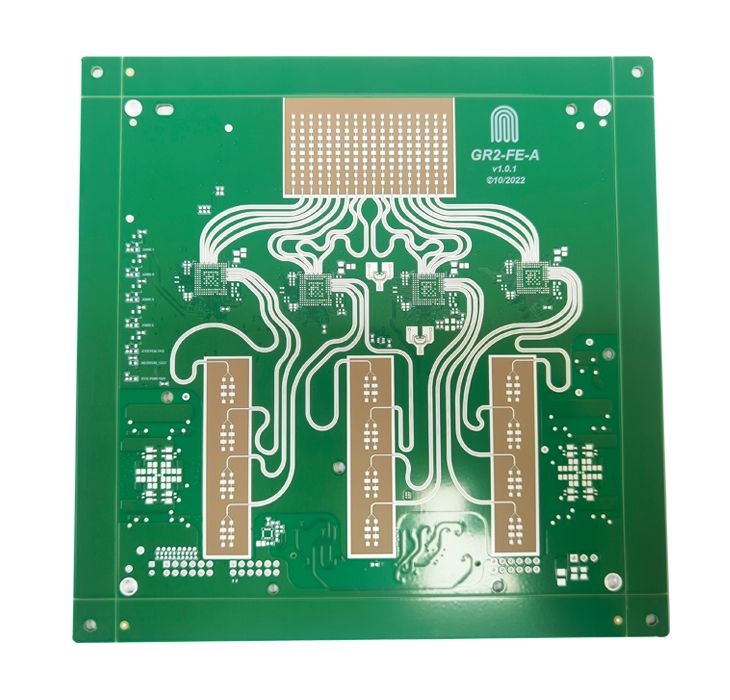

PCB Fabrication with Duroid 5880

PCBs with Duroid 5880 as the substrate can be fabricated using standard PCB manufacturing processes:

Lamination

Multiple layers of Duroid 5880 prepreg are laminated using high temperature and pressure to form a multi-layer board. The prepreg flows well for uniform lamination.

Drilling

The laminated board is drilled with small holes for creating plated-through holes (PTHs) to interconnect layers. Duroid 5880 has good drillability.

Metallization

The holes are plated with copper to create the PTH interconnects. Standard electroless copper plating can be used with Duroid 5880.

Etching

Unwanted copper is etched away to form the desired circuit pattern on the PCB. Duroid 5880 is compatible with standard etchants.

Solder mask

A solder mask is applied over the PCB for insulating exposed copper from solder and protecting circuits. Duroid 5880 accepts most liquid photoimageable solder masks.

FQA

What are some key benefits of using Duroid 5880?

Some key benefits are low loss, excellent dielectric stability, high frequency capability, good thermal conductivity and strong peel strength. This combination of properties makes it highly suitable for demanding microwave applications.

Does Duroid 5880 require any special PCB fabrication processes?

No, standard PCB manufacturing processes including lamination, drilling, plating, etching and solder mask application can be used to fabricate boards with Duroid 5880. No special tools or processes are required.

What is the typical dielectric constant of Duroid 5880?

Duroid 5880 has a dielectric constant of 2.20 at 10 GHz. This remains stable over frequency, temperature and humidity variations.

What are some typical applications of Duroid 5880?

Typical applications include radar and satellite communication circuits, microwave radio links, missile guidance systems, microwave test equipment and aerospace electronics.

What is the maximum operating temperature for Duroid 5880?

Duroid 5880 offers stable performance over a wide temperature range from -60°C to 100°C making it suitable for demanding applications. The high thermal conductivity also aids thermal management.

Leave a Reply