Understanding Common PCB Soldering Defects

Printed circuit boards (PCBs) are essential components in modern electronics, providing a platform for electrical components to be mounted and interconnected. The process of soldering these components onto the PCB is crucial for ensuring reliable electrical connections and overall circuit functionality. However, various defects can occur during the soldering process, leading to poor performance or even complete failure of the PCB assembly.

In this article, we will explore the common types of PCB soldering defects, their causes, and methods for prevention and correction. By understanding these defects and implementing best practices in soldering techniques, manufacturers can improve the quality and reliability of their PCB assemblies.

Types of PCB Soldering Defects

Several types of defects can occur during the PCB soldering process. These defects can be categorized based on their appearance and the underlying causes. Some of the most common PCB soldering defects include:

- Bridging

- Cold joints

- Insufficient solder

- Excessive solder

- Solder balls

- Tombstoning

- Lifted pads

- Solder flags or spikes

Bridging

Bridging is a defect that occurs when excess solder creates an unintended connection between two or more adjacent pads or traces. This can lead to short circuits and improper circuit functioning. Bridging can be caused by several factors, such as:

- Excessive solder paste application

- Incorrect component placement

- Inadequate solder mask design

- High soldering temperature or prolonged soldering time

To prevent bridging, it is essential to control the amount of solder paste applied, ensure accurate component placement, design proper solder mask clearances, and optimize soldering temperature and time.

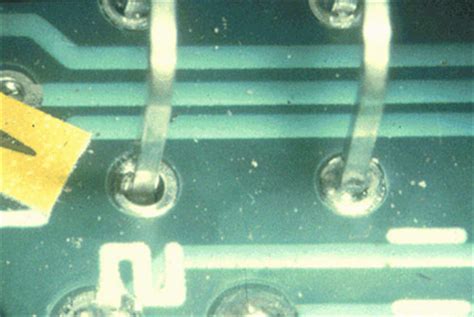

Cold Joints

Cold joints occur when the solder fails to melt completely or when there is insufficient wetting of the solder to the pad and component lead. This results in a weak, brittle connection that is prone to cracking and failure. Cold joints can be caused by:

- Insufficient soldering temperature

- Inadequate flux activation

- Contaminated or oxidized surfaces

- Improper soldering technique

To prevent cold joints, ensure that the soldering temperature is adequate, use fresh and active flux, clean and prepare the surfaces before soldering, and follow proper soldering techniques.

Insufficient Solder

Insufficient solder defects occur when there is not enough solder to create a proper connection between the component lead and the pad. This can lead to weak or intermittent connections. Causes of insufficient solder include:

- Inadequate solder paste application

- Incorrect solder stencil design

- Insufficient soldering time or temperature

- Component placement issues

To prevent insufficient solder defects, ensure adequate solder paste application, design proper solder stencils, optimize soldering parameters, and verify component placement accuracy.

Excessive Solder

Excessive solder defects occur when too much solder is applied to the joint, resulting in a bulky or domed appearance. While excessive solder may not always cause immediate problems, it can lead to issues such as bridging, increased joint stress, and difficulties in inspection. Causes of excessive solder include:

- Overprinting of solder paste

- Incorrect solder stencil design

- Excessive soldering time or temperature

- Manual soldering with too much solder

To prevent excessive solder defects, control the amount of solder paste applied, design appropriate solder stencils, optimize soldering parameters, and use the correct amount of solder during manual soldering.

Solder Balls

Solder balls are small, spherical particles of solder that can form during the reflow soldering process. They can cause short circuits if they come into contact with adjacent pads or traces. Solder balls can be caused by:

- Excessive solder paste

- High soldering temperature

- Inadequate flux activation

- Contamination on the PCB surface

To prevent solder balls, control the amount of solder paste applied, optimize soldering temperature, ensure proper flux activation, and maintain a clean PCB surface.

Tombstoning

Tombstoning, also known as drawbridging, is a defect that occurs when a surface-mount component stands up on one end, resembling a tombstone. This can happen when there is an imbalance in the surface tension of the molten solder on the component pads. Causes of tombstoning include:

- Uneven heating of the component pads

- Incorrect component placement

- Mismatched pad sizes or shapes

- Inadequate solder paste volume

To prevent tombstoning, ensure even heating of the component pads, accurate component placement, matched pad sizes and shapes, and appropriate solder paste volume.

Lifted Pads

Lifted pads occur when the pad on the PCB separates from the substrate during the soldering process. This can lead to broken connections and component detachment. Lifted pads can be caused by:

- Poor PCB design or manufacturing

- Excessive soldering temperature or time

- Mechanical stress during component placement or removal

- Contamination or oxidation of the pad surface

To prevent lifted pads, ensure proper PCB design and manufacturing quality, control soldering temperature and time, minimize mechanical stress, and maintain clean and oxide-free pad surfaces.

Solder Flags or Spikes

Solder flags or spikes are sharp, pointed protrusions of solder that can occur on the edges of solder joints. While they may not always cause immediate issues, they can lead to short circuits or mechanical interference. Solder flags or spikes can be caused by:

- Excessive soldering time or temperature

- Incorrect soldering technique

- Contamination or oxidation on the component leads or pads

To prevent solder flags or spikes, control soldering time and temperature, use proper soldering techniques, and ensure clean and oxide-free surfaces on component leads and pads.

Preventing and Correcting PCB Soldering Defects

Preventing PCB soldering defects requires a combination of proper design, material selection, process control, and operator training. Some key strategies for preventing soldering defects include:

-

Design for manufacturability (DFM): Ensure that the PCB design follows best practices for solder pad sizes, shapes, and spacing to minimize the risk of defects.

-

Material selection: Choose high-quality PCB substrates, solder paste, and components that are compatible with the soldering process and meet the required specifications.

-

Process control: Monitor and control critical soldering parameters such as temperature, time, and atmosphere to ensure consistent and reliable solder joint formation.

-

Operator training: Provide adequate training to operators involved in the soldering process, covering topics such as component placement, soldering techniques, and defect identification.

When soldering defects do occur, there are several methods for correction, depending on the type and severity of the defect. Some common correction methods include:

-

Rework: Manually remove the defective solder joint and resolder the component using appropriate techniques and tools.

-

Solder paste touch-up: Apply additional solder paste to the defective joint and reflow the PCB to correct insufficient solder or cold joint defects.

-

Solder wick or vacuum desoldering: Use solder wick or a vacuum desoldering tool to remove excess solder from bridged or excessive solder joints.

-

Component replacement: If a component is damaged or improperly soldered, remove it from the PCB and replace it with a new component.

It is important to note that while correction methods can address some soldering defects, preventing defects through proper design, process control, and operator training is always preferable to minimize rework and maximize PCB assembly quality.

Visual Inspection and Testing

Visual inspection and testing are critical steps in identifying and addressing PCB soldering defects. By incorporating these processes into the manufacturing workflow, manufacturers can catch defects early, reduce rework costs, and improve overall product quality.

Visual Inspection Techniques

Visual inspection is the first line of defense in identifying soldering defects. Inspectors use various techniques and tools to examine solder joints and detect anomalies. Some common visual inspection techniques include:

-

Manual inspection: Trained operators visually examine the PCB assembly using magnification tools such as magnifying glasses or microscopes to identify defects.

-

Automated optical inspection (AOI): AOI systems use high-resolution cameras and image processing algorithms to automatically detect soldering defects based on predefined criteria.

-

X-ray inspection: X-ray systems allow inspectors to examine solder joints that are hidden under components or within the PCB, enabling the detection of defects such as voids or insufficient solder.

When conducting visual inspections, inspectors look for specific characteristics of solder joints that indicate the presence of defects. These characteristics include:

- Solder joint shape and size

- Wetting angle and coverage

- Presence of voids, cracks, or contamination

- Alignment and placement of components

By comparing the observed solder joint characteristics with established quality standards and acceptance criteria, inspectors can identify defects and determine the need for rework or correction.

Electrical Testing

In addition to visual inspection, electrical testing is essential for verifying the functionality and reliability of PCB assemblies. Electrical testing can help detect soldering defects that may not be visually apparent but can still impact circuit performance. Some common electrical testing methods include:

-

In-circuit testing (ICT): ICT involves using a bed-of-nails fixture to make electrical contact with specific points on the PCB and measure the electrical characteristics of the components and interconnections.

-

Flying probe testing: Flying probe testers use movable probes to make electrical contact with test points on the PCB, allowing for flexible and programmable testing of various circuit parameters.

-

Functional testing: Functional testing involves applying power to the PCB and verifying that it performs according to its specified requirements, such as signal integrity, timing, and input/output functionality.

Electrical testing can help identify soldering defects such as open circuits, short circuits, and component failures. By combining visual inspection and electrical testing, manufacturers can achieve a comprehensive evaluation of PCB assembly quality and ensure that the final product meets the required performance and reliability standards.

Best Practices for PCB Soldering

To minimize the occurrence of soldering defects and improve the overall quality of PCB assemblies, manufacturers should adopt best practices throughout the soldering process. Some key best practices include:

-

Use of solder paste stencils: Solder paste stencils help ensure consistent and accurate application of solder paste to the PCB pads. Proper stencil design and maintenance are crucial for achieving reliable solder joints.

-

Reflow profile optimization: The reflow soldering profile should be optimized based on the specific requirements of the PCB assembly, considering factors such as component thermal constraints, solder paste specifications, and PCB substrate characteristics.

-

Nitrogen atmosphere soldering: Soldering in a nitrogen atmosphere helps reduce oxidation and improve solder joint quality by minimizing the formation of oxides on the solder surface.

-

Cleanliness and contamination control: Maintaining a clean and contamination-free environment is essential for preventing soldering defects. This includes regular cleaning of the PCB surface, stencils, and soldering equipment, as well as using high-quality, contamination-free materials.

-

Operator training and qualification: Providing comprehensive training and qualification programs for operators involved in the soldering process helps ensure consistent and reliable solder joint formation. Operators should be trained on proper techniques for component placement, soldering, and defect identification.

-

Process monitoring and control: Implementing process monitoring and control systems, such as statistical process control (SPC), helps identify trends and variations in the soldering process, enabling timely corrective actions to prevent defects.

By adopting these best practices and continuously monitoring and improving the soldering process, manufacturers can significantly reduce the occurrence of soldering defects and enhance the overall quality and reliability of their PCB assemblies.

Frequently Asked Questions (FAQ)

-

What is the most common type of PCB soldering defect?

The most common type of PCB soldering defect is bridging, which occurs when excess solder creates an unintended connection between adjacent pads or traces. -

How can I prevent tombstoning defects during PCB soldering?

To prevent tombstoning defects, ensure even heating of the component pads, accurate component placement, matched pad sizes and shapes, and appropriate solder paste volume. -

What are the main causes of cold solder joints?

The main causes of cold solder joints include insufficient soldering temperature, inadequate flux activation, contaminated or oxidized surfaces, and improper soldering technique. -

How can visual inspection help identify PCB soldering defects?

Visual inspection techniques, such as manual inspection, automated optical inspection (AOI), and X-ray inspection, allow inspectors to examine solder joint characteristics and detect defects based on predefined quality criteria. -

What are some best practices for minimizing PCB soldering defects?

Some best practices for minimizing PCB soldering defects include using solder paste stencils, optimizing reflow profiles, soldering in a nitrogen atmosphere, maintaining cleanliness and contamination control, providing operator training and qualification, and implementing process monitoring and control systems.

By understanding the common types of PCB soldering defects, their causes, and methods for prevention and correction, manufacturers can improve the quality and reliability of their PCB assemblies. Implementing best practices in soldering techniques, visual inspection, and electrical testing, along with continuous process improvement, can help minimize defects and ensure the production of high-quality PCB assemblies.

Table: Common PCB Soldering Defects and Their Causes

| Defect Type | Causes |

|---|---|

| Bridging | – Excessive solder paste application – Incorrect component placement – Inadequate solder mask design – High soldering temperature or prolonged soldering time |

| Cold Joints | – Insufficient soldering temperature – Inadequate flux activation – Contaminated or oxidized surfaces – Improper soldering technique |

| Insufficient Solder | – Inadequate solder paste application – Incorrect solder stencil design – Insufficient soldering time or temperature – Component placement issues |

| Excessive Solder | – Overprinting of solder paste – Incorrect solder stencil design – Excessive soldering time or temperature – Manual soldering with too much solder |

| Solder Balls | – Excessive solder paste – High soldering temperature – Inadequate flux activation – Contamination on the PCB surface |

| Tombstoning | – Uneven heating of the component pads – Incorrect component placement – Mismatched pad sizes or shapes – Inadequate solder paste volume |

| Lifted Pads | – Poor PCB design or manufacturing – Excessive soldering temperature or time – Mechanical stress during component placement or removal – Contamination or oxidation of the pad surface |

| Solder Flags or Spikes | – Excessive soldering time or temperature – Incorrect soldering technique – Contamination or oxidation on the component leads or pads |

Leave a Reply