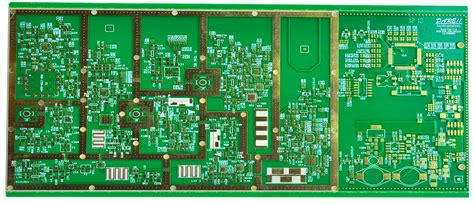

What is FR4 PCB?

FR4 PCB, also known as Flame Retardant 4 Printed Circuit Board, is a type of PCB material that is widely used in the electronics industry. It is a composite material made from woven fiberglass cloth with an epoxy resin binder that is flame resistant. FR4 PCB is known for its excellent mechanical, electrical, and thermal properties, making it an ideal choice for a wide range of applications.

Composition of FR4 PCB

FR4 PCB is composed of two main materials: fiberglass and epoxy resin. The fiberglass is woven into a cloth and then impregnated with the epoxy resin. The resulting material is then cured under heat and pressure to create a strong, durable, and flame-resistant board.

The fiberglass used in FR4 PCB is typically E-glass, which is a type of glass that is known for its excellent electrical insulation properties. The epoxy resin used in FR4 PCB is a thermoset plastic that is known for its excellent mechanical and thermal properties.

Properties of FR4 PCB

FR4 PCB has several properties that make it an ideal choice for a wide range of applications. These properties include:

-

High mechanical strength: FR4 PCB has excellent mechanical strength, making it resistant to bending, twisting, and impact.

-

Excellent electrical insulation: FR4 PCB has excellent electrical insulation properties, making it suitable for use in high-voltage applications.

-

Good thermal stability: FR4 PCB has good thermal stability, meaning it can withstand high temperatures without deforming or losing its mechanical properties.

-

Flame resistance: FR4 PCB is flame resistant, meaning it will not easily catch fire or spread flames.

-

Low water absorption: FR4 PCB has low water absorption, meaning it is resistant to moisture and humidity.

| Property | Value |

|---|---|

| Dielectric Constant | 4.5-5.5 |

| Dielectric Loss Tangent | 0.02-0.04 |

| Thermal Conductivity | 0.3-0.4 W/mK |

| Thermal Expansion Coefficient | 13-16 ppm/°C |

| Flexural Strength | 450-550 MPa |

| Tensile Strength | 350-450 MPa |

| Water Absorption | 0.1-0.2% |

Yellowing of FR4 PCB

One of the main concerns with FR4 PCB is yellowing. Yellowing of FR4 PCB can occur due to several factors, including exposure to high temperatures, humidity, and UV light. Yellowing can also occur due to the presence of certain additives in the epoxy resin, such as bromine-based flame retardants.

Causes of Yellowing in FR4 PCB

-

High temperatures: Exposure to high temperatures can cause the epoxy resin in FR4 PCB to degrade and turn yellow.

-

Humidity: Exposure to high humidity can cause the fiberglass in FR4 PCB to absorb moisture, leading to yellowing and other defects.

-

UV light: Exposure to UV light can cause the epoxy resin in FR4 PCB to degrade and turn yellow.

-

Bromine-based flame retardants: The presence of bromine-based flame retardants in the epoxy resin can cause yellowing of FR4 PCB over time.

Effects of Yellowing on FR4 PCB

Yellowing of FR4 PCB can have several negative effects on the performance and reliability of the board. These effects include:

-

Reduced mechanical strength: Yellowing of FR4 PCB can cause the board to become brittle and lose its mechanical strength, making it more susceptible to cracking and breaking.

-

Reduced electrical insulation: Yellowing of FR4 PCB can cause the board to lose its electrical insulation properties, leading to increased leakage current and reduced signal integrity.

-

Reduced thermal stability: Yellowing of FR4 PCB can cause the board to lose its thermal stability, making it more susceptible to warping and deformation at high temperatures.

-

Reduced aesthetics: Yellowing of FR4 PCB can make the board look old and worn, reducing its aesthetic appeal.

Solutions to Yellowing of FR4 PCB

There are several solutions to the problem of yellowing in FR4 PCB. These solutions include:

Use of Non-Brominated Flame Retardants

One of the main causes of yellowing in FR4 PCB is the presence of bromine-based flame retardants in the epoxy resin. To reduce yellowing, manufacturers can use non-brominated flame retardants instead. Non-brominated flame retardants are less likely to cause yellowing and are also more environmentally friendly.

Examples of non-brominated flame retardants include:

- Phosphorus-based flame retardants

- Nitrogen-based flame retardants

- Inorganic flame retardants

Use of UV Stabilizers

Another way to reduce yellowing in FR4 PCB is to use UV stabilizers in the epoxy resin. UV stabilizers are additives that absorb UV light and prevent it from damaging the epoxy resin. This can help to reduce yellowing and extend the life of the board.

Examples of UV stabilizers include:

- Benzotriazoles

- Benzophenones

- Triazines

Use of High-Quality Raw Materials

The quality of the raw materials used in FR4 PCB can also affect the likelihood of yellowing. Using high-quality fiberglass and epoxy resin can help to reduce yellowing and improve the overall performance and reliability of the board.

Comparison of FR4 PCB with Other PCB Materials

FR4 PCB is just one of many types of PCB materials available. Other common PCB materials include:

- Polyimide (PI)

- Polytetrafluoroethylene (PTFE)

- Ceramic

- Aluminum

Each of these materials has its own unique properties and advantages. The following table compares the properties of FR4 PCB with these other materials:

| Material | Dielectric Constant | Dielectric Loss Tangent | Thermal Conductivity (W/mK) | Thermal Expansion Coefficient (ppm/°C) | Flexural Strength (MPa) | Tensile Strength (MPa) | Water Absorption (%) |

|---|---|---|---|---|---|---|---|

| FR4 | 4.5-5.5 | 0.02-0.04 | 0.3-0.4 | 13-16 | 450-550 | 350-450 | 0.1-0.2 |

| PI | 3.5-4.5 | 0.001-0.005 | 0.2-0.3 | 12-20 | 350-450 | 250-350 | 0.3-0.5 |

| PTFE | 2.1-2.3 | 0.0002-0.001 | 0.2-0.3 | 50-120 | 20-30 | 20-30 | 0.01-0.03 |

| Ceramic | 6-10 | 0.001-0.005 | 20-30 | 5-7 | 300-400 | 200-300 | 0.0-0.05 |

| Aluminum | 8-9 | 0.01-0.02 | 150-200 | 23-24 | 300-400 | 200-300 | 0.0-0.1 |

As can be seen from the table, each material has its own strengths and weaknesses. FR4 PCB is a good all-around material with excellent mechanical, electrical, and thermal properties. However, it is not the best choice for every application.

For example, if a high degree of thermal conductivity is required, aluminum or ceramic may be a better choice. If low dielectric loss is required, PTFE may be a better choice. If high temperature resistance is required, PI may be a better choice.

FAQ

-

What is the difference between FR4 PCB and other types of PCB?

FR4 PCB is a specific type of PCB material that is made from woven fiberglass cloth and epoxy resin. It is known for its excellent mechanical, electrical, and thermal properties, as well as its flame resistance. Other types of PCB materials, such as polyimide, PTFE, ceramic, and aluminum, have their own unique properties and advantages. -

Can yellowing of FR4 PCB be prevented?

Yes, yellowing of FR4 PCB can be prevented or reduced through the use of non-brominated flame retardants, UV stabilizers, and high-quality raw materials. However, it is not always possible to completely eliminate yellowing, especially in applications where the board is exposed to high temperatures, humidity, or UV light. -

Is FR4 PCB suitable for all applications?

No, FR4 PCB is not suitable for all applications. While it is a good all-around material with excellent properties, there may be other materials that are better suited for specific applications. For example, if a high degree of thermal conductivity is required, aluminum or ceramic may be a better choice. -

What are the advantages of using non-brominated flame retardants in FR4 PCB?

Non-brominated flame retardants are less likely to cause yellowing of FR4 PCB compared to bromine-based flame retardants. They are also more environmentally friendly and less toxic. However, they may not provide the same level of flame resistance as bromine-based flame retardants. -

How does the quality of raw materials affect the performance of FR4 PCB?

The quality of the raw materials used in FR4 PCB, such as the fiberglass and epoxy resin, can have a significant impact on the performance and reliability of the board. Using high-quality raw materials can help to reduce yellowing, improve mechanical and electrical properties, and extend the life of the board. On the other hand, using low-quality raw materials can lead to defects, reduced performance, and premature failure of the board.

Conclusion

FR4 PCB is a widely used material in the electronics industry due to its excellent mechanical, electrical, and thermal properties, as well as its flame resistance. However, one of the main concerns with FR4 PCB is yellowing, which can occur due to exposure to high temperatures, humidity, UV light, and certain additives in the epoxy resin.

To reduce yellowing and improve the performance and reliability of FR4 PCB, manufacturers can use non-brominated flame retardants, UV stabilizers, and high-quality raw materials. While FR4 PCB is a good all-around material, it may not be the best choice for every application, and other materials such as polyimide, PTFE, ceramic, and aluminum may be better suited for specific requirements.

Overall, understanding the properties, advantages, and limitations of FR4 PCB and other PCB materials is essential for selecting the right material for a given application and ensuring the best possible performance and reliability of the finished product.

Leave a Reply