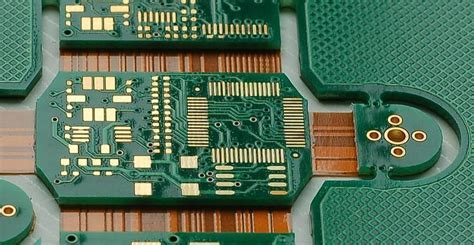

Introduction to Rigid-Flex PCB

Rigid-flex PCB is a type of printed circuit board that combines the benefits of both rigid and flexible PCBs. It consists of rigid PCB sections connected by flexible PCB sections, allowing for a more compact and reliable design compared to using separate rigid and flexible PCBs. Rigid-flex PCBs are increasingly being used in various electronic projects due to their numerous advantages over traditional flexible PCBs.

What is a Rigid-Flex PCB?

A rigid-flex PCB is a hybrid printed circuit board that incorporates both rigid and flexible substrates. The rigid sections provide structural support and stability, while the flexible sections allow for bending and folding of the PCB to fit into tight spaces or conform to unique shapes. The rigid and flexible sections are laminated together to form a single, integrated PCB.

Advantages of Rigid-Flex PCB

- Space Savings: Rigid-flex PCBs enable a more compact design by eliminating the need for separate rigid and flexible PCBs and their associated connectors.

- Increased Reliability: The integrated design of rigid-flex PCBs reduces the number of interconnects and solder joints, resulting in improved reliability and reduced risk of connection failures.

- Enhanced Flexibility: The flexible sections of rigid-flex PCBs allow for bending and folding, enabling the PCB to fit into tight spaces or conform to unique shapes.

- Improved Signal Integrity: Rigid-flex PCBs offer better signal integrity compared to separate rigid and flexible PCBs due to reduced interconnects and shorter signal paths.

- Cost Reduction: Although the initial cost of rigid-flex PCBs may be higher, they can lead to overall cost savings by reducing assembly time, eliminating connectors, and improving reliability.

Applications of Rigid-Flex PCB

Rigid-flex PCBs find applications in various industries and electronic projects where space constraints, reliability, and flexibility are critical factors. Some common applications include:

Consumer Electronics

Rigid-flex PCBs are widely used in consumer electronics, such as smartphones, tablets, laptops, and wearable devices. They enable compact designs, reduce weight, and improve durability by eliminating the need for separate rigid and flexible PCBs and their associated connectors.

Medical Devices

Medical devices often require compact and reliable PCBs that can withstand repeated use and sterilization processes. Rigid-flex PCBs are well-suited for medical applications, such as implantable devices, diagnostic equipment, and wearable health monitors, due to their ability to fit into small spaces and provide reliable performance.

Aerospace and Defense

In aerospace and defense applications, PCBs must withstand harsh environments, vibrations, and extreme temperatures. Rigid-flex PCBs offer a robust and reliable solution by reducing the number of interconnects and providing a more secure and stable design compared to separate rigid and flexible PCBs.

Automotive Electronics

Rigid-flex PCBs are increasingly being used in automotive electronics, such as infotainment systems, driver assistance systems, and electronic control units (ECUs). They enable compact designs, improve reliability, and withstand the harsh environmental conditions encountered in automotive applications.

Designing Rigid-Flex PCB

Designing a rigid-flex PCB requires careful consideration of various factors to ensure optimal performance and reliability. Some key aspects to consider when designing rigid-flex PCBs include:

Layer Stack-up

The layer stack-up of a rigid-flex PCB determines the number and arrangement of rigid and flexible layers. It is essential to select the appropriate materials and thicknesses for each layer to ensure the desired flexibility and durability of the PCB.

Bend Radius

The bend radius is a critical parameter in rigid-flex PCB design, as it determines the minimum radius at which the flexible sections can be bent without causing damage or stress to the PCB. The bend radius should be carefully calculated based on the thickness and material properties of the flexible layers.

Signal Integrity

Maintaining signal integrity is crucial in rigid-flex PCB design, especially for high-speed and high-frequency applications. Proper signal routing, impedance matching, and shielding techniques should be employed to minimize crosstalk, reflections, and electromagnetic interference (EMI).

Mechanical Considerations

Rigid-flex PCBs must be designed to withstand the mechanical stresses associated with bending and folding. Proper placement of components, reinforcement of flexible sections, and strain relief techniques should be incorporated to ensure the long-term reliability of the PCB.

Manufacturing Rigid-Flex PCB

Manufacturing rigid-flex PCBs involves a combination of processes used for both rigid and flexible PCBs. Some key steps in the manufacturing process include:

Material Selection

Selecting the appropriate materials for the rigid and flexible sections of the PCB is crucial for achieving the desired performance and reliability. Common materials used for rigid-flex PCBs include FR-4, polyimide, and adhesives with specific properties to ensure proper bonding and flexibility.

Lamination

The rigid and flexible layers are laminated together using specialized equipment and processes to ensure a strong and reliable bond. The lamination process involves applying heat and pressure to the stack-up of materials to create a single, integrated PCB.

Drilling and Plating

Holes are drilled through the rigid and flexible sections of the PCB to accommodate components and interconnects. The holes are then plated with copper to provide electrical connectivity between layers.

Patterning and Etching

The copper layers are patterned and etched to create the desired circuit traces and pads. This process involves applying a photoresist, exposing it to UV light through a photomask, and then etching away the unwanted copper.

Solder Mask and Silkscreen

A solder mask is applied to the PCB to protect the copper traces and prevent short circuits. Silkscreen printing is used to add component designators, logos, and other markings to the PCB for ease of assembly and identification.

Advantages of Rigid-Flex PCB over Flexible PCB

While both rigid-flex PCBs and flexible PCBs offer benefits in terms of flexibility and space savings, rigid-flex PCBs have several advantages over traditional flexible PCBs:

Increased Durability

Rigid-flex PCBs are more durable than flexible PCBs due to the presence of rigid sections that provide structural support and stability. The rigid sections help to protect the flexible sections from excessive bending and stress, improving the overall reliability of the PCB.

Better Signal Integrity

Rigid-flex PCBs offer better signal integrity compared to flexible PCBs due to the reduced number of interconnects and shorter signal paths. The integrated design of rigid-flex PCBs minimizes the need for connectors and long traces, reducing the risk of signal degradation and interference.

Reduced Assembly Time

Rigid-flex PCBs can significantly reduce assembly time compared to using separate rigid and flexible PCBs. The integrated design eliminates the need for manual assembly of connectors and cables, streamlining the manufacturing process and reducing the risk of human error.

Cost Savings

Although the initial cost of rigid-flex PCBs may be higher than flexible PCBs, they can lead to overall cost savings in the long run. The reduced assembly time, eliminated connectors, and improved reliability can result in lower manufacturing and maintenance costs over the life of the product.

Challenges and Considerations

While rigid-flex PCBs offer numerous advantages, there are also some challenges and considerations to keep in mind when using them in electronic projects:

Design Complexity

Designing rigid-flex PCBs can be more complex than designing separate rigid and flexible PCBs. The integration of rigid and flexible sections requires careful consideration of various factors, such as bend radius, layer stack-up, and signal integrity, to ensure optimal performance and reliability.

Higher Initial Cost

The initial cost of rigid-flex PCBs can be higher compared to using separate rigid and flexible PCBs due to the specialized materials, processes, and equipment required for manufacturing. However, the long-term cost savings and benefits often outweigh the initial investment.

Limited Flexibility

While rigid-flex PCBs offer flexibility in the flexible sections, they are not as flexible as pure flexible PCBs. The presence of rigid sections limits the overall flexibility of the PCB, which may not be suitable for applications requiring extreme bending or folding.

Manufacturing Challenges

Manufacturing rigid-flex PCBs can be more challenging than manufacturing separate rigid and flexible PCBs. The lamination process, which involves bonding the rigid and flexible layers together, requires specialized equipment and precise control to ensure a reliable and durable bond.

FAQ

-

What is the difference between rigid-flex PCB and flexible PCB?

Rigid-flex PCB is a hybrid PCB that combines rigid and flexible sections, while flexible PCB is entirely flexible. Rigid-flex PCB offers the benefits of both rigid and flexible PCBs, providing structural support and flexibility in a single, integrated design. -

Can rigid-flex PCBs be used in high-temperature applications?

Yes, rigid-flex PCBs can be designed to withstand high temperatures by selecting appropriate materials and using specialized manufacturing processes. High-temperature materials, such as polyimide and high-Tg FR-4, can be used to ensure the PCB’s performance and reliability in high-temperature environments. -

How does the cost of rigid-flex PCB compare to flexible PCB?

The initial cost of rigid-flex PCB is typically higher than flexible PCB due to the specialized materials, processes, and equipment required for manufacturing. However, rigid-flex PCBs can lead to overall cost savings in the long run through reduced assembly time, eliminated connectors, and improved reliability. -

What are the typical applications of rigid-flex PCB?

Rigid-flex PCBs find applications in various industries, including consumer electronics, medical devices, aerospace and defense, and automotive electronics. They are particularly well-suited for applications requiring compact designs, high reliability, and flexibility, such as smartphones, wearable devices, implantable medical devices, and avionics systems. -

Can rigid-flex PCBs be repaired or reworked?

Repairing or reworking rigid-flex PCBs can be more challenging compared to traditional rigid or flexible PCBs due to the integrated nature of the design. However, with proper techniques and equipment, minor repairs and rework can be performed on rigid-flex PCBs. It is essential to follow the manufacturer’s guidelines and use specialized tools to avoid damaging the PCB during the repair process.

Conclusion

Rigid-flex PCBs offer numerous advantages over traditional flexible PCBs in electronic projects, including space savings, increased reliability, enhanced flexibility, improved signal integrity, and potential cost reductions. By combining the benefits of rigid and flexible PCBs into a single, integrated design, rigid-flex PCBs enable more compact, reliable, and versatile electronic devices across various industries.

However, designing and manufacturing rigid-flex PCBs also presents some challenges and considerations, such as design complexity, higher initial costs, limited flexibility, and manufacturing challenges. It is essential to carefully evaluate the specific requirements of the project and weigh the benefits and challenges of using rigid-flex PCBs before making a decision.

As technology continues to advance and the demand for compact and reliable electronic devices grows, rigid-flex PCBs are likely to play an increasingly important role in the development of innovative and high-performance electronic projects.

Leave a Reply