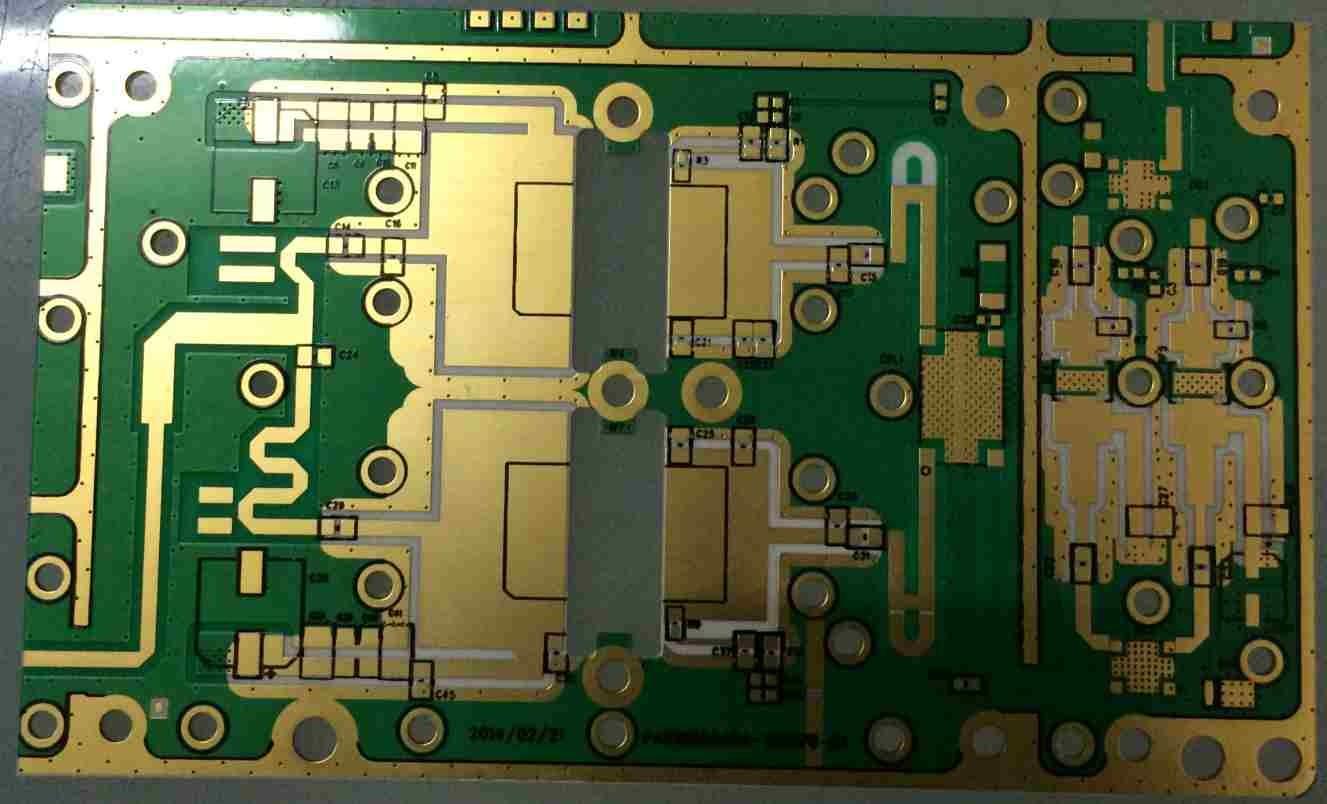

The Rogers RO4835 is a high-performance laminate material that has gained popularity in the electronics industry due to its impressive electrical properties. This material is a woven glass-reinforced hydrocarbon/ceramic laminate that is designed to provide excellent electrical stability and low dielectric loss. It is commonly used in high-frequency applications such as power amplifiers, antennas, and filters.

One of the key benefits of the Rogers RO4835 material is its ability to maintain its electrical properties over a wide range of frequencies and temperatures. This makes it an ideal choice for applications that require stable performance in harsh environments. Additionally, the material has a low coefficient of thermal expansion, which helps to reduce stress on the components and ensure reliable performance over time.

Overall, the Rogers RO4835 material is a high-quality laminate that offers excellent electrical properties and stability. Its versatility and reliability make it a popular choice for a wide range of applications in the electronics industry.

Rogers RO4835 Overview

Rogers RO4835 is a high-frequency circuit material that is designed to provide excellent electrical performance at frequencies up to 40 GHz. The material is a ceramic-filled hydrocarbon laminate that has a dielectric constant of 3.48 and a dissipation factor of 0.0037 at 10 GHz. It is widely used in applications such as antennas, cellular base stations, and high-speed digital designs.

One of the key benefits of Rogers RO4835 is its low loss tangent, which makes it ideal for use in high-frequency applications where signal attenuation is a concern. The material also has a low coefficient of thermal expansion, which helps to ensure that circuits maintain their performance over a wide temperature range.

Rogers RO4835 is available in a range of thicknesses, from 4 mils to 40 mils, making it suitable for a variety of applications. The material is also compatible with a range of processing techniques, including laser drilling, mechanical drilling, and routing.

Overall, Rogers RO4835 is a reliable and high-performance circuit material that is well-suited for a range of high-frequency applications. Its excellent electrical properties and compatibility with various processing techniques make it a popular choice among engineers and designers who require high-quality circuit materials.

Key Features of Rogers RO4835

Thermal Performance

Rogers RO4835 is a high-frequency circuit material that offers superior thermal performance. Its low thermal coefficient of expansion (TCE) ensures that it can withstand extreme temperatures without losing its electrical properties. The material has a high glass transition temperature (Tg) of 200°C, making it ideal for use in high-temperature applications.

RO4835 also has a low dissipation factor (Df) of 0.003 at 10 GHz, which means that it generates less heat than other circuit materials. This low Df is particularly important in high-frequency applications where heat dissipation can affect the performance of the circuit.

Electrical Stability

In addition to its thermal performance, Rogers RO4835 also offers excellent electrical stability. The material has a low dielectric constant (Dk) of 3.48 at 10 GHz, which makes it ideal for high-frequency applications. Its low Dk ensures that it has a low signal loss and a high signal speed, making it ideal for use in high-speed digital circuits.

RO4835 also has a tight tolerance on its Dk, which ensures that the material’s electrical properties remain consistent over time. This consistency is essential in applications where the circuit’s performance must remain stable over a long period.

Overall, Rogers RO4835 is a high-performance circuit material that offers superior thermal performance and electrical stability. Its low dissipation factor and low dielectric constant make it ideal for use in high-frequency applications, while its tight tolerance on Dk ensures that its electrical properties remain consistent over time.

Applications of Rogers RO4835

Communication Systems

Rogers RO4835 is a high-frequency laminate material that is widely used in the design and manufacture of communication systems. This material has excellent electrical properties, including low dielectric loss, high thermal conductivity, and low moisture absorption. These properties make it ideal for high-frequency applications such as antennas, filters, and amplifiers.

The material’s low dielectric loss and high thermal conductivity make it ideal for applications that require high power handling capabilities. Additionally, its low moisture absorption helps maintain the electrical properties of the material over a wide range of temperatures and humidities.

Automotive Radar

Rogers RO4835 is also used in the design and manufacture of automotive radar systems. These systems are used to detect and avoid obstacles in the road, making them an essential component of modern driver assistance systems.

The material’s excellent electrical properties, combined with its ability to withstand high temperatures and harsh operating conditions, make it an ideal choice for automotive radar applications. Additionally, the material’s high thermal conductivity helps dissipate heat generated by the radar system, ensuring reliable and accurate performance.

In conclusion, Rogers RO4835 is a versatile material that is widely used in communication systems and automotive radar applications. Its excellent electrical properties, high thermal conductivity, and low moisture absorption make it an ideal choice for high-frequency and high-power applications.

Rogers RO4835 Manufacturing Process

Rogers RO4835 material is a high-frequency laminate with a dielectric constant of 3.48 and a loss tangent of 0.0037. The manufacturing process of this material involves several steps, including resin mixing, prepreg production, and lamination.

The resin mixing process involves combining the resin, hardener, and filler materials in a specific ratio. The mixture is then stirred thoroughly to ensure that the components are evenly distributed. This mixture is then poured onto a release paper and spread evenly using a doctor blade.

The prepreg production process involves layering the resin mixture onto a layer of fiberglass cloth. The fiberglass cloth is then rolled to ensure that the resin mixture is evenly distributed. The prepreg is then cut to the required size and stored in a temperature- and humidity-controlled environment.

The lamination process involves layering the prepreg onto a copper foil and placing it in a press. The press applies heat and pressure to the material to bond the layers together. The resulting material is then cooled and trimmed to the required size.

Overall, the manufacturing process of Rogers RO4835 material involves precise measurements and controlled environments to ensure that the material meets the required specifications.

Handling and Storage of Rogers RO4835

Rogers RO4835 is a high-frequency laminate material that requires careful handling and storage to maintain its integrity and performance. Here are some guidelines to follow when working with RO4835:

Handling

When handling RO4835, it is important to wear gloves and avoid touching the surfaces of the material with bare hands. This is because oils and other contaminants can transfer from the skin to the surface of the material, which can affect its electrical properties. It is also important to handle the material gently and avoid bending or creasing it, as this can cause cracking or delamination.

Storage

RO4835 should be stored in a dry, cool place, away from direct sunlight and sources of heat. The material should be stored flat, with no heavy objects placed on top of it, to prevent warping or deformation. It is also important to store RO4835 in its original packaging or in a protective covering to prevent dust, dirt, and other contaminants from settling on the surface of the material.

Cleaning

If RO4835 becomes contaminated with dust, dirt, or other debris, it can be cleaned using a soft, lint-free cloth and a mild detergent solution. Harsh chemicals or abrasive cleaners should be avoided, as they can damage the surface of the material. After cleaning, the material should be rinsed thoroughly with clean water and dried with a soft cloth or allowed to air dry.

Following these guidelines for handling and storage can help ensure that Rogers RO4835 maintains its electrical properties and performance over time.

Safety Measures for Rogers RO4835

When working with Rogers RO4835, it is important to take certain safety measures to prevent any accidents or injuries. Here are some of the safety measures that should be taken:

- Wear personal protective equipment (PPE) such as gloves, safety glasses, and a respirator when handling Rogers RO4835. This will help protect you from any potential health hazards associated with the material.

- Store Rogers RO4835 in a cool, dry place away from any sources of heat or ignition. This material is flammable and can ignite if exposed to high temperatures or flames.

- Avoid inhaling or ingesting Rogers RO4835. If you accidentally inhale or ingest the material, seek medical attention immediately.

- When cutting or shaping Rogers RO4835, use appropriate tools and techniques to prevent any accidents. Always use a dust mask or respirator to prevent inhaling any dust or particles.

- Dispose of Rogers RO4835 properly. Do not throw it in the trash or pour it down the drain. Follow local regulations for hazardous waste disposal.

By following these safety measures, you can ensure that you are working with Rogers RO4835 safely and effectively. Remember to always read and follow the manufacturer’s instructions and take any necessary precautions.

Conclusion

In conclusion, the Rogers RO4835 is a high-performance laminate material that offers excellent electrical and mechanical properties. It is widely used in a variety of applications, including aerospace, defense, and telecommunications.

One of the key benefits of the RO4835 is its low dielectric constant and loss, which makes it an ideal choice for high-frequency applications. It also has a low coefficient of thermal expansion, which makes it suitable for use in harsh environments where temperature fluctuations are common.

Another advantage of the RO4835 is its high thermal conductivity, which allows it to dissipate heat quickly and efficiently. This property is particularly important in high-power applications where heat buildup can cause performance issues.

Overall, the Rogers RO4835 is a reliable and versatile material that can meet the demands of a wide range of applications. Its combination of high performance and durability make it an excellent choice for engineers and designers looking for a high-quality laminate material.

Leave a Reply