What is Reflow Soldering?

Reflow soldering is a process used in printed circuit board (PCB) assembly to attach surface mount components to the board. It involves applying solder paste, a mixture of tiny solder particles and flux, to the pads on the PCB. The components are then placed onto the solder paste. The entire board is heated in a reflow oven, which melts the solder particles and bonds the components to the pads.

Reflow soldering is an efficient and reliable method for attaching large numbers of small components to a PCB. It allows for high-volume, automated assembly of complex boards with many surface mount devices (SMDs). Compared to other methods like wave soldering, reflow provides more precise control and works well for high-density boards.

The Reflow Soldering Process

The reflow soldering process can be broken down into several key steps:

-

Solder Paste Application: Solder paste is applied to the pads on the PCB, typically using a stencil and squeegee. The stencil has holes that match the pad locations, allowing a precise amount of paste to be deposited.

-

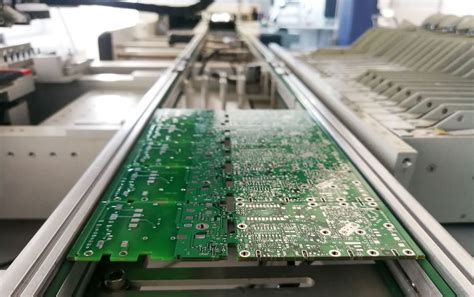

Component Placement: The surface mount components are placed onto the solder paste deposits on the pads. This is often done by automated Pick-and-Place machines for speed and accuracy.

-

Reflow Heating: The PCB is passed through a reflow oven, which has multiple heating zones. The oven heats up gradually to activate the flux, then reaches a peak temperature above the melting point of the solder (217°C for tin-lead solder or 240°C for lead-free). This melts the solder particles, creating electrical and mechanical bonds between the component leads and PCB pads.

-

Cooling: After reaching the peak temperature, the board is cooled in a controlled manner to allow the solder joints to solidify without defects.

-

Inspection: The reflowed boards are visually inspected and may undergo electrical testing and other quality checks.

Here is a table summarizing the typical temperature profile for a tin-lead solder reflow process:

| Zone | Temperature Range (°C) | Time (seconds) |

|---|---|---|

| Preheat | 150-170 | 60-120 |

| Soak | 170-200 | 60-120 |

| Reflow | 200-225 (peak 220) | 30-60 |

| Cooling | Below 200 | 30-60 |

Lead-free solder has a higher melting point, so the peak temperature is around 240-250°C.

Advantages of Reflow Soldering

There are several key benefits to using reflow soldering for PCB Assembly:

High Throughput

Reflow soldering is well-suited for high-volume production. Automated equipment can handle the solder paste application, component placement, and reflow oven processing. This allows large numbers of boards to be assembled quickly and efficiently.

Precision and Consistency

The reflow process provides a high degree of control over the solder joint formation. The solder paste is applied in precise amounts, and the heating profile can be finely tuned. This leads to consistent, reliable solder connections across the board.

Works with High-Density Boards

As electronic devices get smaller and more complex, PCBs need to pack more components into less space. Reflow soldering can handle boards with fine-pitch leads and small pad sizes. It is an enabling technology for miniaturization.

Compatibility with Surface Mount Components

Reflow soldering is the primary method used to attach surface mount devices to PCBs. It works with a wide range of component package types, including chip resistors/capacitors, SOICs, QFPs, BGAs, and more.

Fewer Defects

When the reflow profile is optimized and the process is well-controlled, reflow soldering produces solder joints with a low rate of defects. Common problems like bridging, tombstoning, and insufficient wetting are minimized.

Challenges in Reflow Soldering

While reflow soldering is a robust and capable process, it does have some potential issues to watch out for:

Thermal Damage

The high temperatures used in reflow can cause damage to heat-sensitive components. Parts like electrolytic capacitors, connectors, and batteries may need to be hand soldered after reflow. The board itself and any plastics must also be able to withstand the reflow conditions.

Moisture Sensitivity

Many plastic SMD packages can absorb moisture from the air. If not dried properly before reflow, this moisture can turn to steam and cause the package to crack or “pop.” Components have a moisture sensitivity level (MSL) rating that determines their floor life and drying requirements.

Solder Joint Defects

A variety of defects can occur in reflowed solder joints, such as:

- Bridging – Solder shorts between adjacent pins or pads

- Tombstoning – One end of a component lifts up vertically

- Insufficient Wetting – Solder doesn’t fully coat the pad/lead

- Voids – Trapped gas bubbles in the solder joint

Careful control of the paste deposition, component placement, and reflow profile helps avoid these issues.

Flux Residue

The flux in solder paste is designed to clean the metal surfaces and aid solder wetting. After reflow, flux residues are left behind on the board. While some fluxes are formulated to be “no-clean,” others may require cleaning for high-reliability applications.

Optimizing the Reflow Profile

Getting good results from reflow soldering depends heavily on having the right heating profile. The temperatures and times of the preheat, soak, reflow, and cooling phases must be optimized for the particular solder paste and PCB characteristics. Here are some key considerations:

Ramp Rate

The speed of temperature change, both up and down, affects how the solder and components behave. Heating too fast can cause thermal stress and outgassing. Cooling too slowly lets the solder solidify gradually, which can lead to a dull, pitted surface.

Peak Temperature

The peak temperature has to be high enough to fully melt the solder and allow it to wet the surfaces. However, excessive temperature causes more intermetallic formation, flux burning, and damage to components and the board.

Time Above Liquidus

The liquidus is the temperature above which the solder is completely melted. Sufficient time above liquidus (TAL) is needed to allow the solder to flow and form a good joint. Extending the TAL can help reduce voiding.

Preheat and Soak

Preheating the board and components reduces thermal shock. The soak period lets the board reach a uniform temperature and activates the flux. Soak time and temperature influence wetting and voiding.

Profiling a reflow oven involves attaching thermocouples to the PCB and measuring the actual temperatures reached at each stage. The oven settings are then adjusted to achieve the desired profile. Profiling is especially important when setting up a new product, but periodic checks are also helpful for ensuring consistency.

RAYPCB’s Reflow Soldering Capabilities

At RAYPCB, we are experts in reflow soldering for PCB assembly. Our state-of-the-art facilities are equipped with the latest automated solder paste printers, pick-and-place machines, and reflow ovens. We have extensive experience assembling a wide range of boards, from simple single-sided designs to complex, high-density SMT assemblies.

Our process engineering team optimizes the reflow profile for each PCB design and component mix. We carefully control the paste deposition, component placement, and heating/cooling parameters to ensure reliable solder joints with minimal defects. Automated optical inspection (AOI) and X-ray systems are used to verify the soldering quality.

RAYPCB is also well-versed in the special requirements for lead-free soldering, such as higher processing temperatures and the need for tighter control of the reflow profile. We can handle moisture-sensitive devices and bake out components prior to assembly when needed.

In addition to our reflow soldering services, RAYPCB offers PCB design review, component sourcing, and box build/systems integration. We are your one-stop shop for turning your concepts into finished products.

Frequently Asked Questions

What is the difference between reflow and wave soldering?

Reflow soldering is used for surface mount components, while wave soldering is for through-hole parts. In reflow, solder paste is applied to the pads, the components are placed, and the board is heated to melt the solder. In wave soldering, the board is passed over a wave of molten solder, which wicks up through the holes to coat the leads.

Can reflow soldering be used for through-hole components?

In general, reflow soldering is only suitable for surface mount devices. The solder paste and heating profile are designed for parts that sit on top of the board. Through-hole components typically require wave soldering or hand soldering. However, there are some specialized “intrusive reflow” techniques that can reflow certain types of through-hole parts.

What is the maximum temperature reached during reflow soldering?

The peak reflow temperature depends on the type of solder being used. For traditional tin-lead solder, the maximum is typically around 220-225°C. Lead-free solder has a higher melting point, so peak temperatures of 240-250°C are common.

How do I select the right solder paste for my application?

Solder paste selection involves considering the alloy type (tin-lead vs. lead-free), particle size, flux activity, and printing/reflow behavior. The size and spacing of the pads/leads on your PCB will dictate the particle size. More active fluxes are better for hard-to-solder surfaces but may leave more residue. It’s best to work with your solder paste and PCB assembly suppliers to choose a paste that meets your needs.

What kind of defects can occur in reflow soldering?

Some common reflow soldering defects include:

- Bridging – Solder forms a short between adjacent pads/pins

- Insufficient Wetting – Solder doesn’t fully coat the surfaces, leading to a weak joint

- Tombstoning – One end of a component lifts up vertically due to uneven heating or pad sizes

- Voids – Trapped gases form bubbles in the solder joint

- Solder Balls – Small spheres of solder are scattered on the board

Careful process control and optimization of the reflow profile help minimize these issues.

Conclusion

Reflow soldering is a critical process in the assembly of printed circuit boards with surface mount components. By applying solder paste to the pads, placing the components, and heating the board in a controlled profile, reliable electrical and mechanical bonds are formed.

Reflow soldering enables the efficient, high-volume production of complex PCB assemblies. It provides precise control over the solder joint formation and is compatible with high-density designs. While there are challenges in terms of potential thermal damage, moisture sensitivity, and defects, these can be managed through proper process optimization.

At RAYPCB, we have the expertise and equipment to handle all your reflow soldering needs. From paste printing to component placement to thermal profiling, our team will ensure that your boards are assembled with the highest quality and consistency. Contact us today to learn more about our PCB assembly services.

Leave a Reply