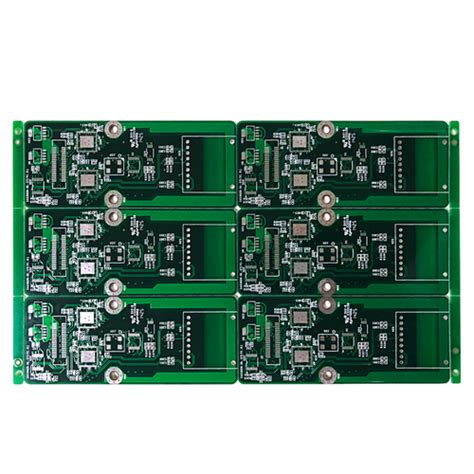

Introduction to High TG PCB

High TG PCB, also known as High-TG-PCB or High Glass Transition Temperature Printed Circuit Board, is a type of PCB that offers enhanced thermal stability and superior performance in high-temperature environments. These PCBs are designed to withstand elevated temperatures without compromising their structural integrity or electrical properties. In this comprehensive article, we will delve into the world of High TG PCBs, exploring their characteristics, manufacturing process, applications, and advantages over traditional PCBs.

What is Glass Transition Temperature (Tg)?

Before we dive into the specifics of High TG PCBs, it’s essential to understand the concept of Glass Transition Temperature (Tg). Tg is the temperature at which a polymer material transitions from a rigid, glassy state to a more flexible, rubbery state. In the context of PCBs, Tg refers to the temperature at which the PCB substrate material begins to soften and lose its mechanical stability.

Standard PCB vs. High TG PCB

Traditional PCBs are typically manufactured using FR-4 substrate material, which has a glass transition temperature of around 130°C to 140°C. While this is sufficient for most standard applications, it may not be adequate for environments where the PCB is exposed to higher temperatures. This is where High TG PCBs come into play.

High TG PCBs are manufactured using specialized substrate materials that have a higher glass transition temperature, typically ranging from 170°C to 200°C or even higher. These materials are formulated with advanced resin systems and reinforcements that provide enhanced thermal stability and resistance to heat-induced deformation.

Characteristics of High TG PCB

Thermal Stability

The primary characteristic of High TG PCBs is their exceptional thermal stability. With a higher glass transition temperature, these PCBs can maintain their structural integrity and mechanical properties even when exposed to elevated temperatures. This makes them ideal for applications where the PCB may encounter high-temperature environments, such as in automotive, aerospace, or industrial settings.

Improved Reliability

High TG PCBs offer improved reliability compared to standard PCBs. The enhanced thermal stability of the substrate material reduces the risk of warping, delamination, or other heat-related failures. This increased reliability is crucial in critical applications where PCB failure can have severe consequences.

Dimensional Stability

Another advantage of High TG PCBs is their dimensional stability. The specialized substrate materials used in their manufacturing process have a lower coefficient of thermal expansion (CTE) compared to standard FR-4. This means that High TG PCBs experience less expansion and contraction when subjected to temperature changes, resulting in improved dimensional stability and reduced stress on components and solder joints.

Electrical Properties

High TG PCBs maintain excellent electrical properties even at elevated temperatures. The advanced resin systems used in their construction provide good dielectric strength, insulation resistance, and low dielectric loss. This ensures reliable electrical performance and signal integrity, even in demanding high-temperature environments.

Manufacturing Process of High TG PCB

The manufacturing process of High TG PCBs follows a similar flow to that of standard PCBs, with a few key differences in material selection and processing parameters.

Substrate Material Selection

The first step in manufacturing High TG PCBs is selecting the appropriate substrate material. As mentioned earlier, these PCBs use specialized materials with higher glass transition temperatures. Some common High TG substrate materials include:

- High Tg FR-4: An enhanced version of the standard FR-4 material with a Tg of around 170°C to 180°C.

- Polyimide (PI): A high-performance polymer with a Tg of up to 260°C, offering excellent thermal stability and mechanical properties.

- PTFE (Teflon): A fluoropolymer with a Tg of around 327°C, known for its low dielectric constant and excellent thermal and chemical resistance.

Circuit Design and Artwork

Once the substrate material is selected, the next step is circuit design and artwork creation. The circuit design is developed based on the specific requirements of the application, taking into account factors such as signal integrity, power distribution, and thermal management. The artwork, which represents the copper patterns on the PCB, is generated using specialized PCB design software.

Lamination and Drilling

The High TG substrate material is then laminated with copper foil to create the base for the PCB. The lamination process involves applying heat and pressure to bond the layers together. After lamination, the PCB panel undergoes drilling to create holes for through-hole components and vias.

Copper Patterning

The drilled PCB panel is then subjected to a series of chemical processes to create the desired copper patterns. This typically involves applying a photoresist coating, exposing it to UV light through a patterned mask, and developing the resist to reveal the desired copper areas. The unwanted copper is then etched away using a chemical etching process, leaving behind the required copper traces and pads.

Solder Mask and Silkscreen

After copper patterning, a solder mask layer is applied to the PCB surface to protect the copper traces and prevent solder bridging during the assembly process. The solder mask also provides insulation and improves the PCB’s appearance. Additionally, a silkscreen layer is often applied to add text, logos, or component identifiers to the PCB surface.

Surface Finish

The final step in the High TG PCB manufacturing process is applying a surface finish to the exposed copper areas. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). The choice of surface finish depends on the specific requirements of the application, such as solderability, durability, and compatibility with the assembly process.

Applications of High TG PCB

High TG PCBs find applications in various industries where reliable performance in high-temperature environments is critical. Some common applications include:

Automotive Electronics

Modern vehicles are equipped with numerous electronic systems that are subjected to high temperatures, especially those located near the engine compartment. High TG PCBs are used in automotive applications such as engine control units, power modules, and sensor interfaces to ensure reliable operation in these challenging conditions.

Aerospace and Defense

Aerospace and defense applications often involve extreme temperature ranges and harsh environmental conditions. High TG PCBs are employed in avionics systems, radar equipment, satellite communications, and military electronics to provide robust performance and long-term reliability.

Industrial Equipment

Industrial equipment, such as power converters, motor drives, and automation systems, often operates in high-temperature environments. High TG PCBs are used in these applications to withstand the elevated temperatures and ensure continuous operation without failure.

LED Lighting

High-power LED lighting systems generate significant heat during operation, which can affect the reliability and lifespan of the PCB and components. High TG PCBs are used in LED lighting applications to provide improved thermal management and ensure long-term performance.

Oil and Gas Industry

The oil and gas industry involves harsh environments with high temperatures, vibrations, and exposure to chemicals. High TG PCBs are used in downhole drilling equipment, sensors, and monitoring systems to withstand these challenging conditions and provide reliable data acquisition and control.

Advantages of High TG PCB

Enhanced Thermal Performance

The primary advantage of High TG PCBs is their enhanced thermal performance. With a higher glass transition temperature, these PCBs can withstand elevated temperatures without compromising their structural integrity or electrical properties. This makes them suitable for applications where the PCB may be exposed to high-temperature environments, ensuring reliable operation and reducing the risk of failure.

Improved Reliability and Longevity

High TG PCBs offer improved reliability and longevity compared to standard PCBs. The specialized substrate materials and advanced resin systems used in their construction provide better resistance to thermal stresses, reducing the likelihood of warping, delamination, or other heat-induced failures. This increased reliability translates to longer product lifetimes and reduced maintenance costs.

Reduced Thermal Expansion and Stress

The lower coefficient of thermal expansion (CTE) of High TG substrate materials results in reduced thermal expansion and contraction when subjected to temperature changes. This dimensional stability minimizes stress on components and solder joints, improving the overall reliability of the PCB assembly. Reduced thermal expansion also helps maintain consistent electrical performance and signal integrity.

Compatibility with High-Temperature Components

High TG PCBs are compatible with high-temperature components, such as ceramic capacitors, high-temperature resistors, and specialized ICs. These components are designed to operate reliably in elevated temperature ranges, and pairing them with High TG PCBs ensures optimal performance and longevity of the entire electronic assembly.

Cost-Effective Solution for Demanding Applications

While High TG PCBs may have a higher initial cost compared to standard PCBs due to the specialized materials and manufacturing processes involved, they offer a cost-effective solution for demanding applications. The improved reliability, longer lifespan, and reduced maintenance requirements associated with High TG PCBs can result in significant cost savings over the product’s lifecycle.

Frequently Asked Questions (FAQ)

- Q: What is the difference between standard FR-4 and High Tg FR-4 substrate materials?

A: Standard FR-4 has a glass transition temperature (Tg) of around 130°C to 140°C, while High Tg FR-4 offers a higher Tg of approximately 170°C to 180°C. The higher Tg of High Tg FR-4 provides enhanced thermal stability and improved performance in high-temperature environments.

- Q: Can High TG PCBs be used with standard PCB assembly processes?

A: Yes, High TG PCBs are compatible with standard PCB assembly processes, such as surface-mount technology (SMT) and through-hole assembly. However, it’s important to consider the temperature ratings of the components and the soldering process to ensure compatibility with the High TG PCB.

- Q: Are High TG PCBs suitable for multilayer designs?

A: Yes, High TG PCBs can be manufactured in multilayer configurations. The specialized substrate materials used in High TG PCBs are available in a range of thicknesses and can be laminated together to create multilayer structures. This allows for the design of complex, high-density PCBs with improved thermal performance.

- Q: How do I select the appropriate High TG substrate material for my application?

A: The selection of the appropriate High TG substrate material depends on the specific requirements of your application. Factors to consider include the operating temperature range, mechanical requirements, electrical properties, and cost constraints. Consulting with a PCB manufacturer or materials expert can help you make an informed decision based on your specific needs.

- Q: Are there any limitations or challenges associated with using High TG PCBs?

A: One potential limitation of High TG PCBs is their higher material cost compared to standard PCBs. Additionally, the specialized substrate materials used in High TG PCBs may have slightly different processing requirements, which can impact manufacturing lead times and availability. However, these challenges are often outweighed by the benefits of improved thermal performance and reliability in demanding applications.

Conclusion

High TG PCBs offer a reliable and robust solution for applications that require enhanced thermal stability and performance in high-temperature environments. By utilizing specialized substrate materials with higher glass transition temperatures, these PCBs can withstand elevated temperatures without compromising their structural integrity or electrical properties. The improved reliability, dimensional stability, and compatibility with high-temperature components make High TG PCBs an ideal choice for industries such as automotive, aerospace, industrial equipment, and oil and gas.

When considering the use of High TG PCBs for your application, it’s essential to carefully evaluate the specific requirements and consult with a reputable PCB manufacturer. By understanding the characteristics, manufacturing process, and advantages of High TG PCBs, you can make an informed decision and ensure the optimal performance and longevity of your electronic assemblies in demanding high-temperature environments.

Leave a Reply